Sintering mold and sintering method of diode with square lead

A square and diode technology, which is applied in the sintering mold and sintering field of diodes, can solve problems such as the inability to maintain the upper and lower flatness of the square leads, exposure, and inconsistent process regulations, etc., and achieve the effect of improving operability and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

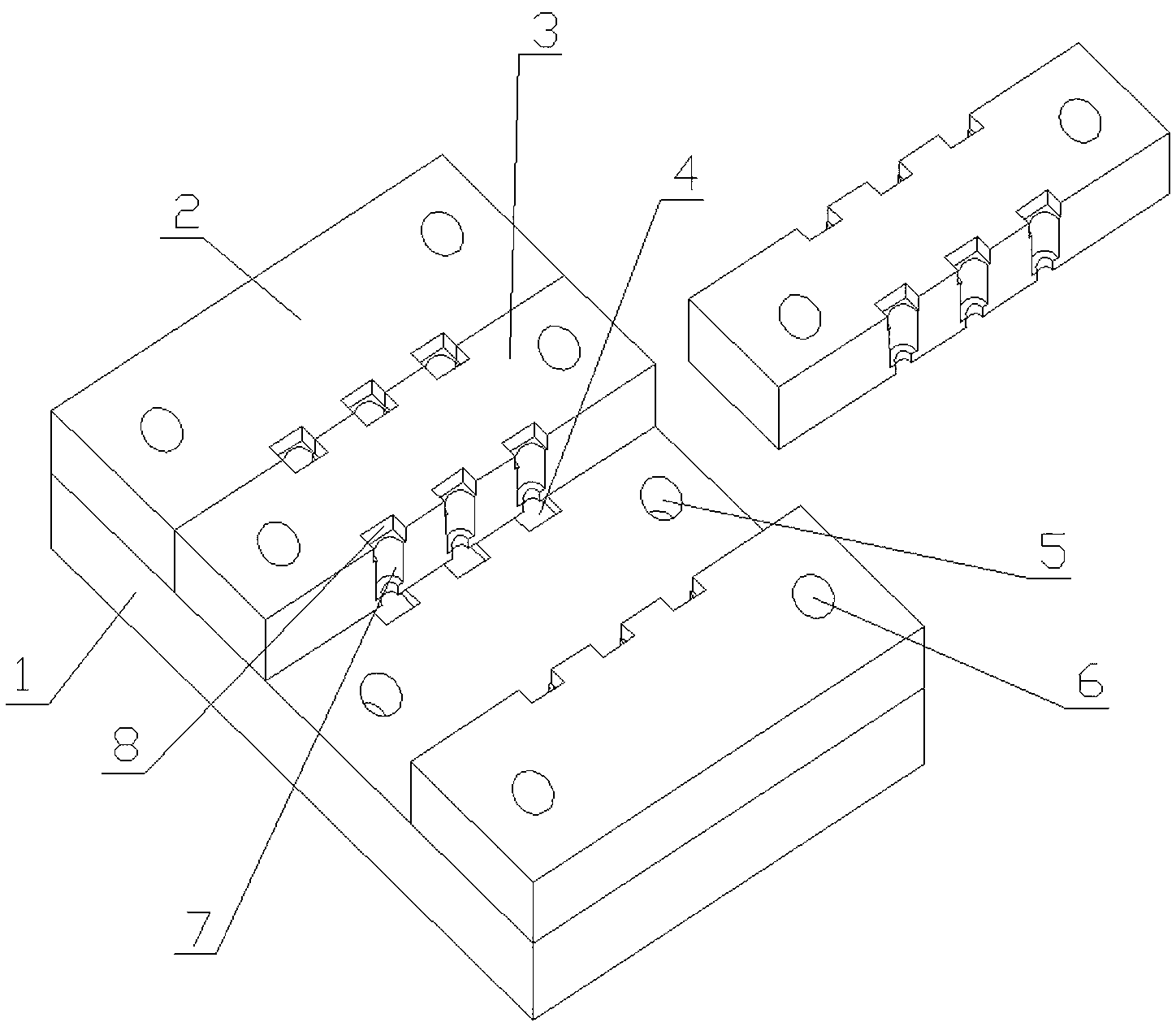

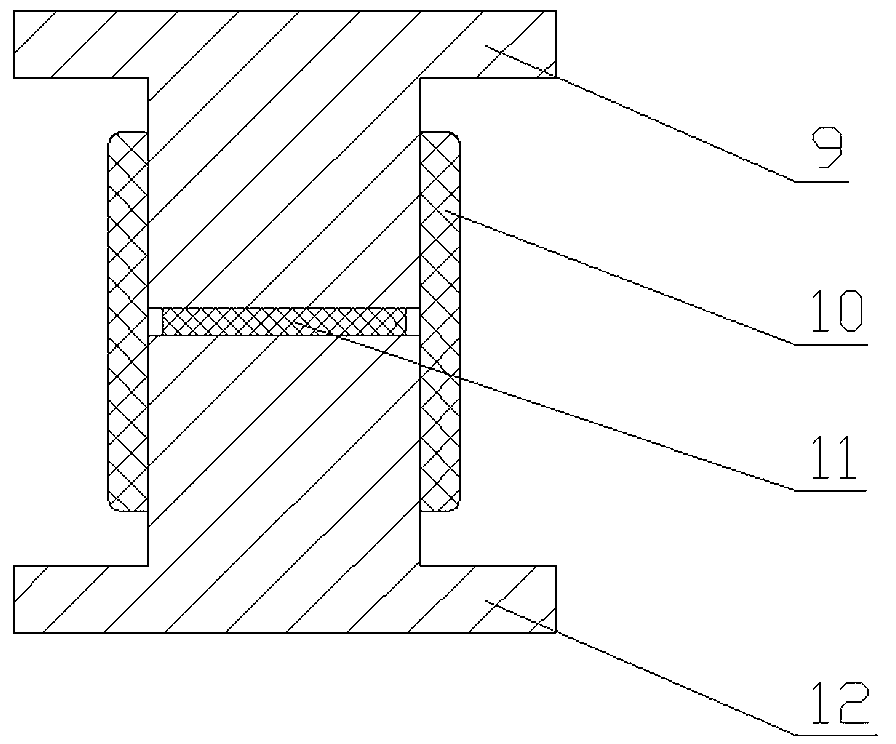

[0015] like figure 1 As shown, the sintering mold includes a base 1 and an upper positioning block. Two rows of diode cavities are arranged on the base and the upper positioning block. Each row has a plurality of diode cavities, and the diode cavities include lower rectangular grooves 4 connected in sequence. , The second-level stepped cylindrical hole 7 and the upper rectangular groove 8, the lower rectangular groove 4 is arranged on the base 1, the lower rectangular groove 4 matches the terminal of the lower square lead wire, and the matching means that the terminal of the lower square lead wire is exactly Can be put into the lower rectangular groove 4. Both the secondary stepped cylindrical hole 7 and the upper rectangular groove 8 are arranged on the upper positioning block, the small end of the secondary stepped cylindrical hole 7 faces downward, and the secondary stepped cylindrical hole 7 is connected with the glass bulb 10 and the lower part exposed outside the glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com