LED with luminous front and rear sides

An LED chip, double-sided technology, applied to LEDs. It can solve the problems of luminous efficiency loss, unidirectional light emission from the packaging substrate, and poor flexibility of LED devices, so as to achieve the effect of reducing costs and reducing space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

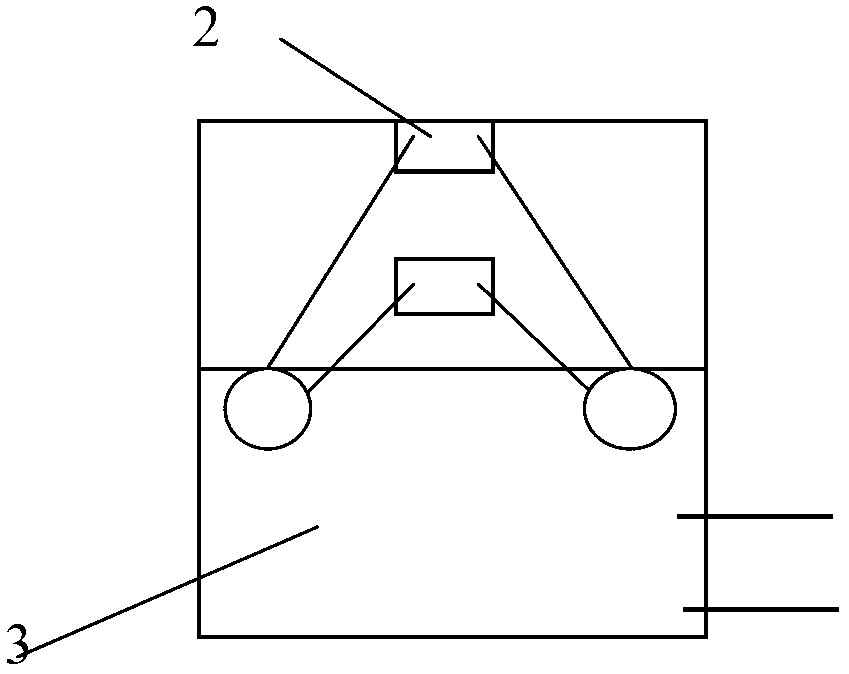

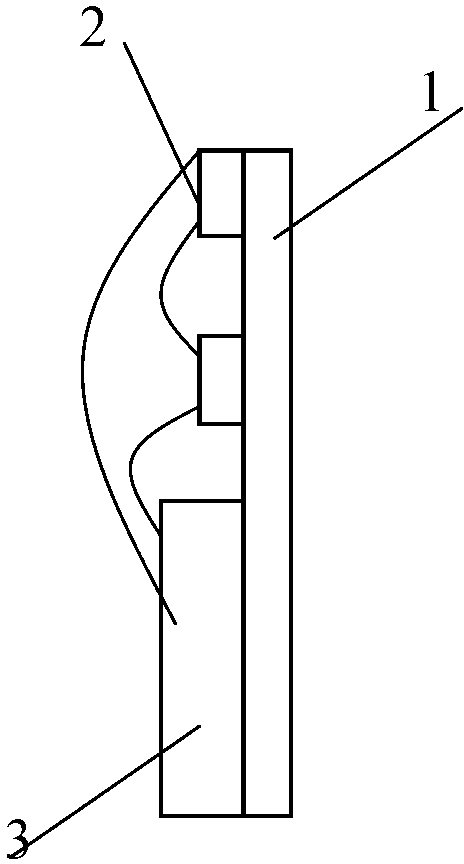

[0020] Such as figure 1 and 2 As shown, a kind of LED that emits light from both front and rear sides includes a glass carrier plate 1 with a thickness of 0.2 mm, and a plurality of LED chips 2 fixedly arranged on the glass carrier plate 1. The substrate of the LED chip is an electroless plated transparent substrate. The LED chips are fixed and arranged on the carrier board through transparent glue. Wherein, the transparent glue is a transparent two-component epoxy resin glue. The glass carrier plate has a light transmission performance of 92%, which can effectively ensure the uniformity of light emitted from both sides.

[0021] On the lower half of the glass carrier, that is, ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com