Automatic cooker

A cooking machine and automatic technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of high labor intensity, affecting the level of dishes, and difficult to control the heat, and achieve the effect of consistent flavor, stable level, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

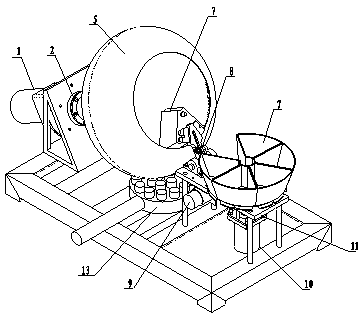

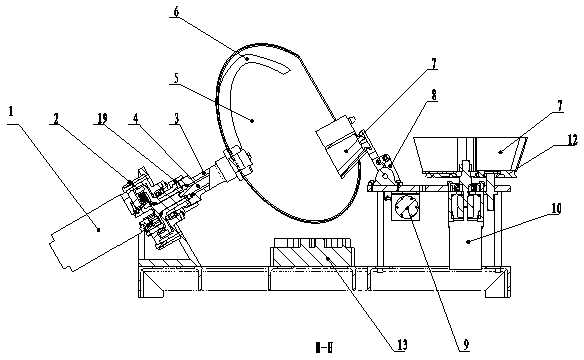

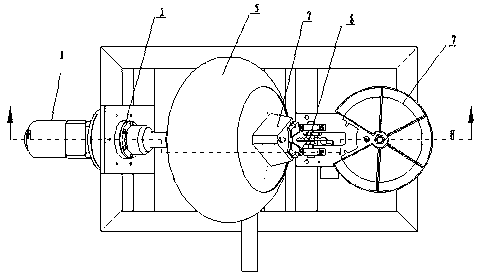

[0022] Shown in the figure, the present invention comprises speed-regulating motor 1, stir-fry variable speed mechanism 2, cooking pot 5, agitator 6, material box 7, material box rotating mechanism 11, feeding mechanism 8, programmable controller 17.

[0023] Shown in the figure, frying pan 5 is positioned at the top of gas stove 13, and frying pan 5 is placed obliquely, and the center of the bottom of frying pan 5 is connected with the rotating shaft of stir-fry speed change mechanism 2, and stir-fry speed change mechanism 2 is installed on the frame, adjusts The speed motor 1 is connected with the stir-fry speed change mechanism 2, and drives the stir-fry speed change mechanism 2 and the frying pan 5 to rotate.

[0024] Shown in the figure, stir-frying speed change mechanism 2 is made up of gear box 20, ring gear 21, sun gear 22, planetary gear 23, frying pan rotating shaft 3, agitator rotating shaft 4. The rotating shaft 3 of the frying pan is a hollow shaft, which is sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com