Separating ring of high-gradient magnetic separator

A high-gradient magnetic separator and magnetic separator technology, applied in the field of machinery, can solve problems such as difficulty in unloading medium concentrate, insufficient separation space, and affecting equipment processing capacity, etc., and achieve simple and reliable structure, low cost, and increased productivity. The effect of large sorting space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

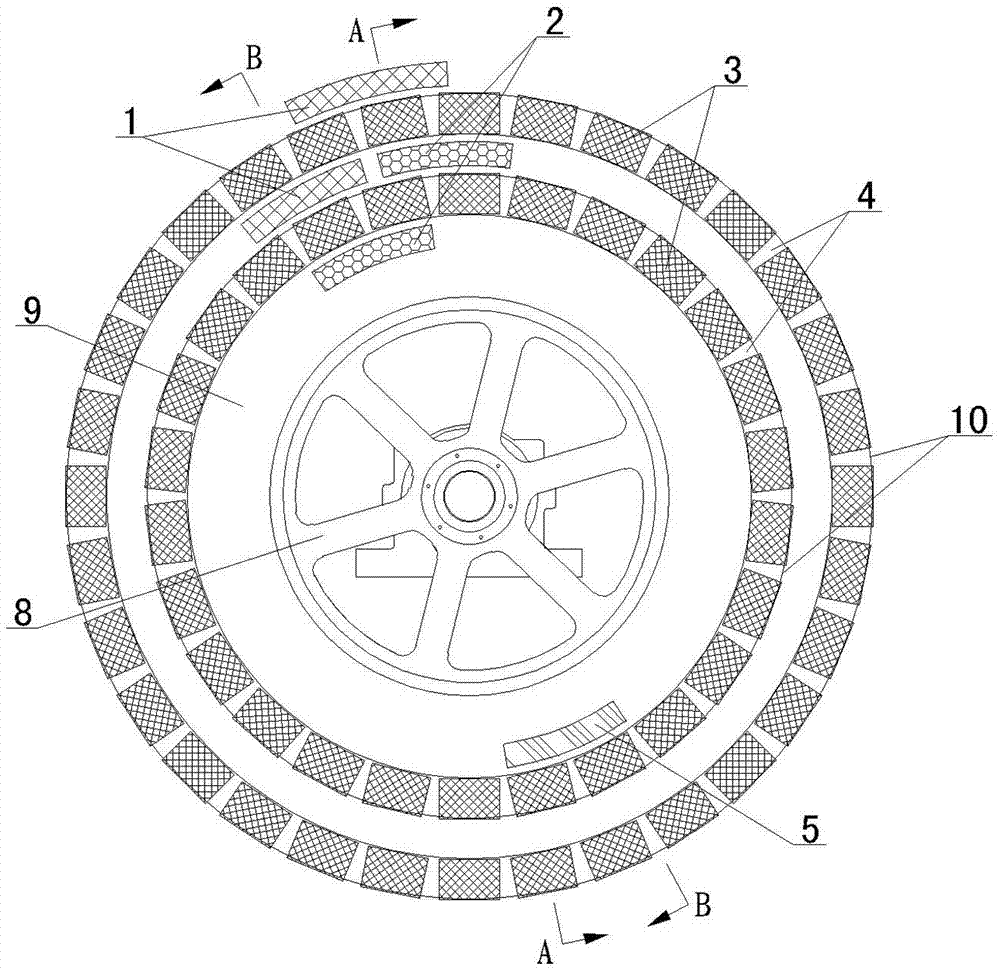

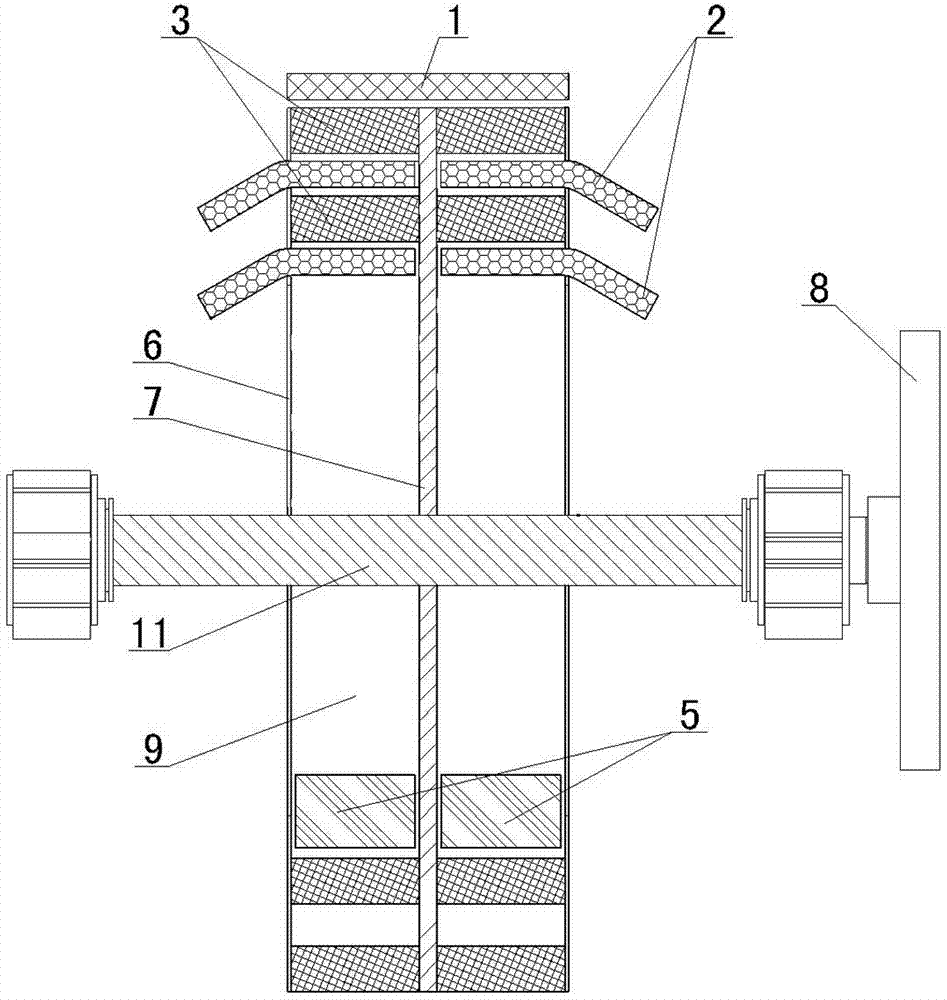

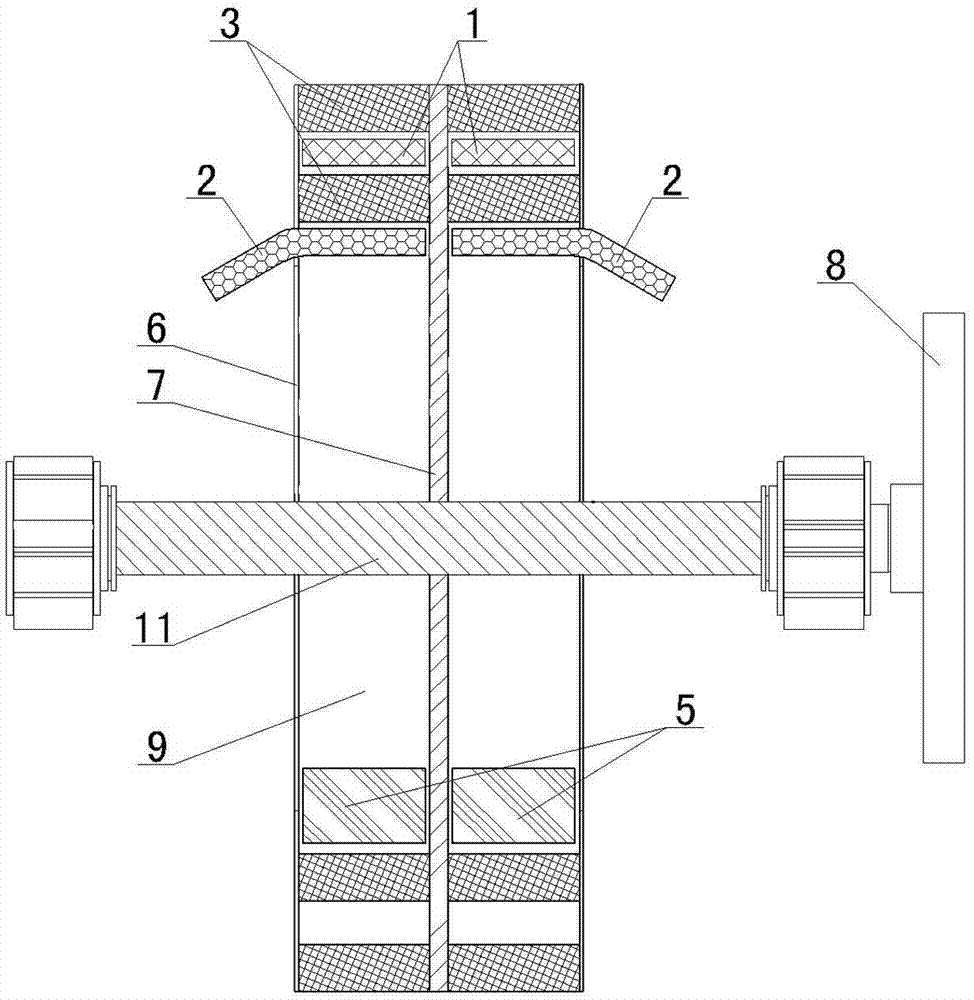

[0020] Such as Figure 1-Figure 6 As shown, the separation ring of the high-gradient magnetic separator of the present invention includes a ring body 9 that is installed on the turntable 8 of the magnetic separator and can rotate synchronously with the turntable and at least two rings that are installed on the periphery of the ring body 9. Layers are used to accommodate and fix the arc groove 10 of the medium box 3, the medium box 3, the ore unloading device 1 installed on the outer periphery of each arc groove 10, the ore receiving device 2 respectively installed on the inner periphery of each arc groove 10, and the The ore feeder 5 in the annulus 9. Wherein, the above-mentioned medium boxes 3 are welded by magnetically conductive stainless steel rods (medium) according to certain rules, and a partition 4 is arranged between two adjacent medium boxes 3 . The medium can gather magnetic force lines in the magnetic field, so a magnetic field with a high gradient can be formed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com