Dust collecting device for foaming cement board production line

A technology of foamed cement board and dust removal device, which is applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of working environment and operator influence, large dust, etc., achieve high collection efficiency, ensure health, and improve work environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

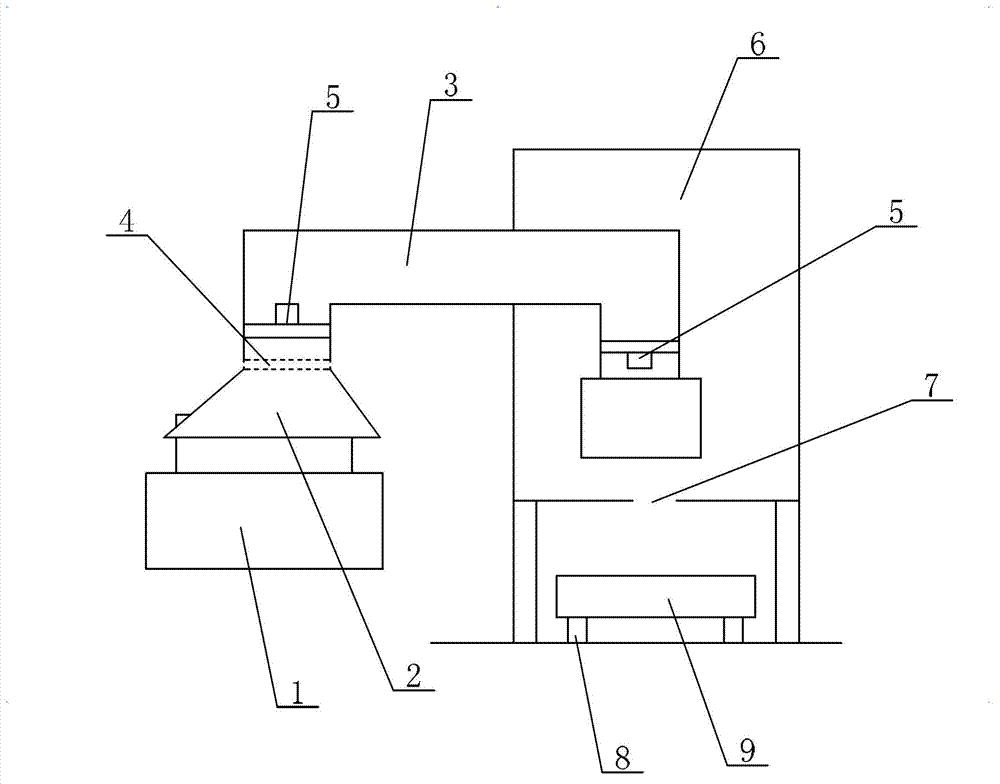

[0012] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0013] see figure 1 as shown, figure 1 It is a structural schematic diagram of the dust removal device for the foamed cement board production line provided in Embodiment 1 of the present invention.

[0014] In this embodiment, a dust removal device for a foamed cement board production line includes a windshield 2 arranged above the foamed cement board cutting machine 1, and the windshield 2 is an inverted funnel-shaped structure to ensure that the foamed cement board cutting machine 1. When cutting, the dust is caused to scatter around, which is convenient for collection. The wind cover 2 is connected to the dust collector 6 through the ventilation duct 3, and the two ends of the ventilation duct 3 are equipped with induced draft fans 5, and the wind cover 2 is connected with the ventilation duct. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com