A thermoforming mold temperature detection and control system

A mold temperature and control system technology, which is applied in the field of thermoforming mold temperature detection and control system, can solve the problems of consistent cooling speed, impact on the quality of hot stamping parts, and inability to accurately control the mold temperature, so as to improve stability and save energy. The effect of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific implementation plan

[0031] In the following, the specific structure and implementation of the present invention will be further described through examples and with reference to the drawings.

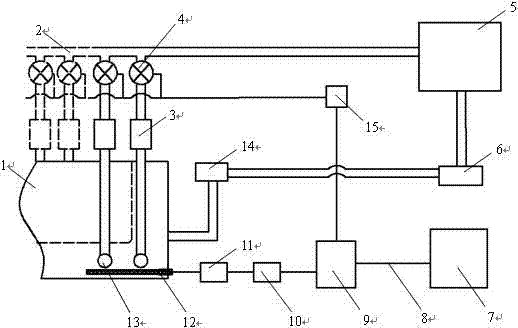

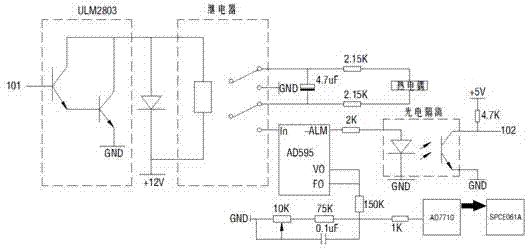

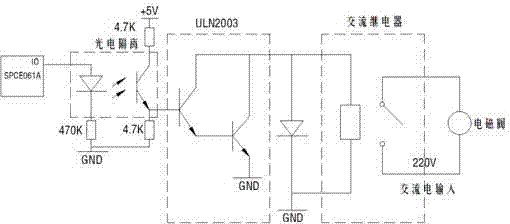

[0032] Such as figure 1 As shown, the thermoforming mold temperature control system described in the patent of the present invention includes a temperature detection system and a temperature control system; wherein the temperature detection system includes a thermocouple 12, a signal amplifier 11, an A / D converter 10, a single chip microcomputer 9, a wire 8 and Temperature display and data storage module 7; temperature control system includes cooling water pipe 2, flow meter 3, solenoid valve 4, cooling water tank 5, waste water tank 14, refrigeration cycle machine 6, single chip microcomputer 9, relay 15 and cooling water channel 13.

[0033] The working process of the whole system is as follows: the thermocouple 12 detects the temperature of the mold 1 in real time, and conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com