Method for manufacturing tire components

A manufacturing method and component technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of high fluidity and insufficient gas release, and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

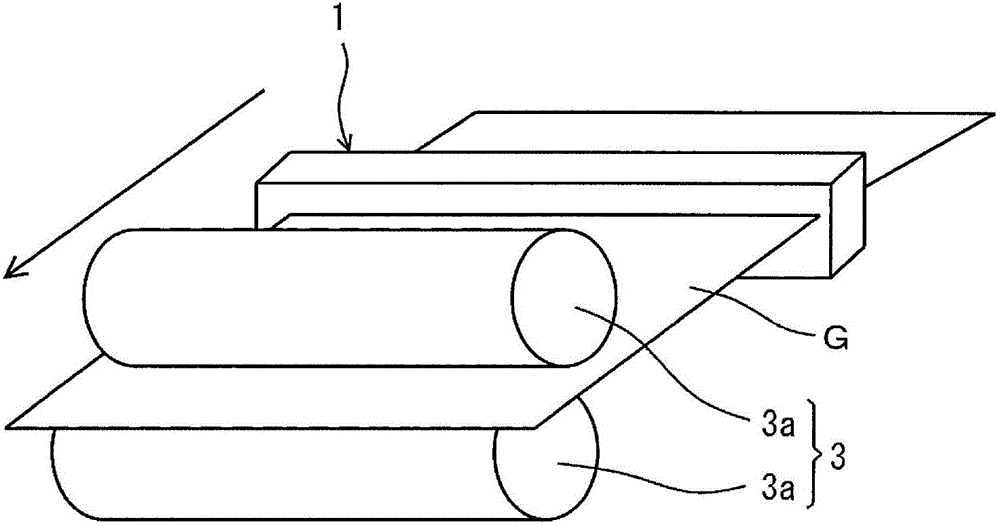

Method used

Image

Examples

Embodiment

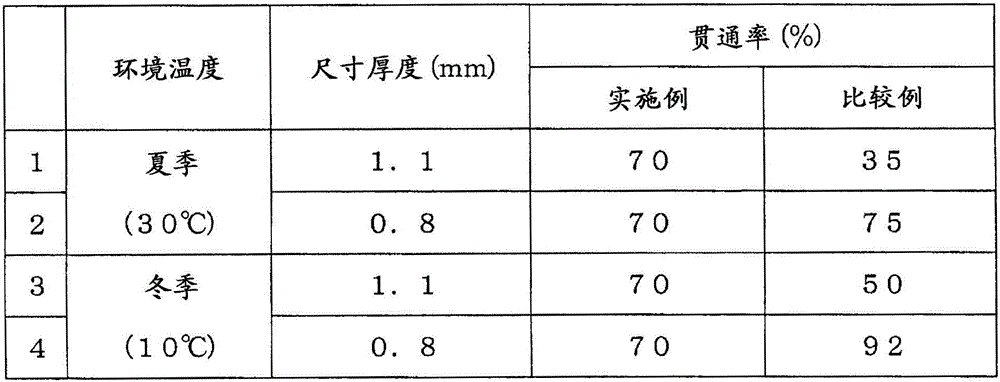

[0033] Next, the present invention will be described in more detail based on examples. Hereinafter, for two sheet-like tire components with different sizes and thicknesses, the change in penetration rate based on the presence or absence of the cooling process is measured.

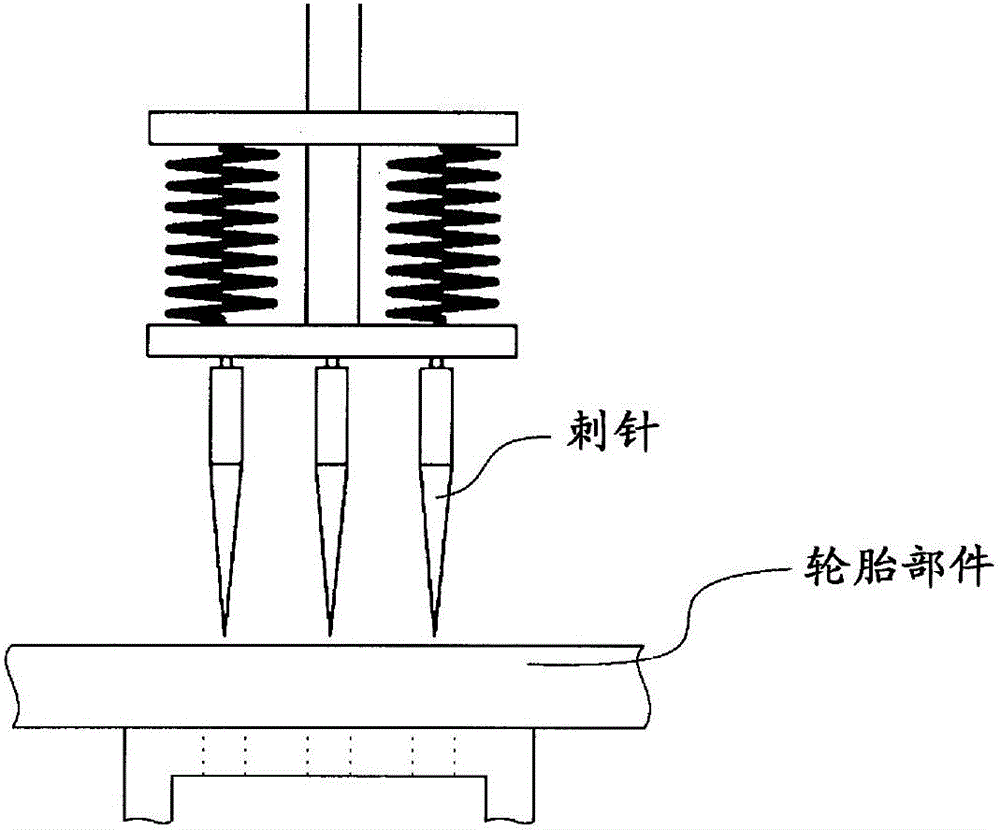

[0034] In the summer environment temperature (30℃) and winter environment temperature (10℃), two sizes and thicknesses (0.8mm and 1.1mm) of sheet tire components (both widths are about 1445mm) are produced. For each sheet tire component, The puncture was performed under a temperature condition of 90°C so that the penetration rate per 300 mm length became 60 to 85%.

[0035] A part of each sheet-like tire component was cooled by a roller arranged at a position 100 mm from the puncture device. Among them, the roller circulates water as a cooling medium inside, and the surface temperature is set at 10°C in summer and 25°C in winter so that the surface temperature is between the puncture temperature and the ambient...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com