Paper tube machine

A paper tube machine and rack technology, which is used in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as low efficiency and easy adhesion of paper tubes up and down, so as to ensure product quality, uniform gluing, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific examples.

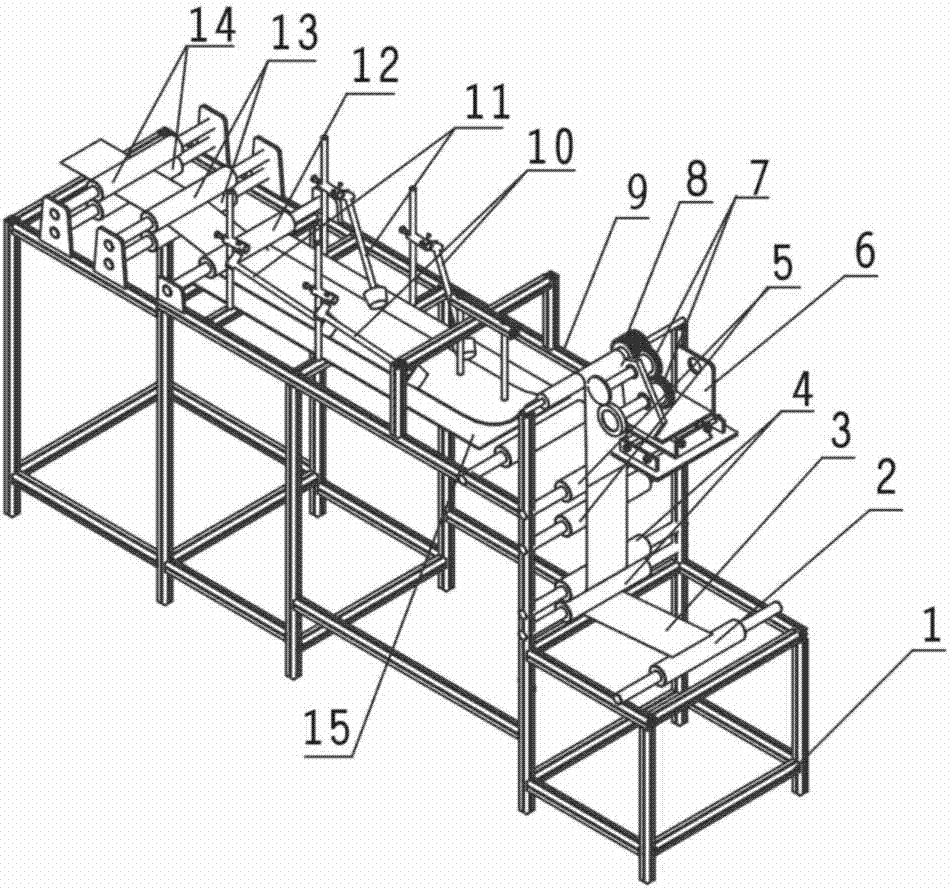

[0010] refer to figure 1 , the paper tube machine includes a large frame 9, a small frame 1, a tightening paper guide wheel combination 10, a tightening paper guide wheel combination 11, a traction guide wheel combination 13 and a traction guide wheel combination 2 14 , upper paper shaft 2, bridge template 15, damping paper roller combination one 4, damping paper roller combination two 5, damping paper roller combination three 12, upper rubber wheel 7, glue holder 6 and synchronous gear 8; upper paper shaft 2 is located On the small frame 1; damping paper roller combination 1 4, damping paper roller combination 2 5 (multiple sets of damping paper roller combinations can be set, and one group can also be set) set on the large frame 9 on the side of the small frame 1 At the side end, a glue frame 6 is arranged on the upper part of damping paper roller combination 1 4 , damping ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap