A concrete pipe pile mold spreader

A technology of concrete pipe piles and molds, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of cumbersome mechanisms, inconvenient work, high maintenance costs, etc., and achieve the effects of eliminating potential safety hazards, improving work efficiency, and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

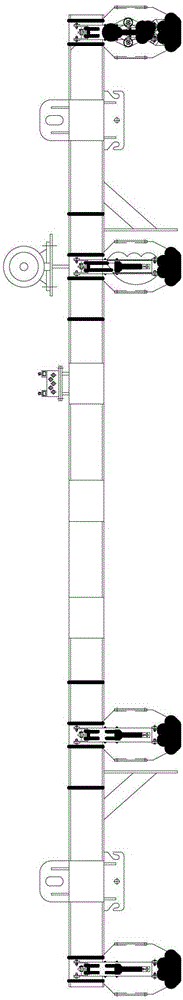

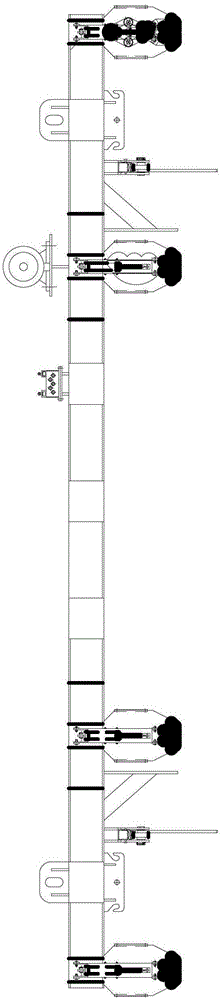

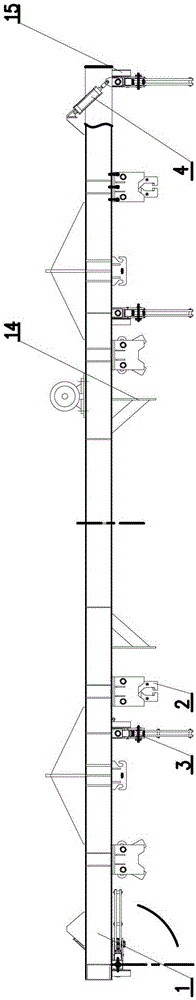

[0023] like Figure 3-6 The shown concrete pipe pile mold hanger includes a beam 1, four cover mold grab hooks 2 and four bottom mold grab hooks 3, the bottom mold grab hooks 3 are hinged with the beam 1, and the bottom mold grab hooks 3 also pass through the first piston Type reciprocating mechanism 4 is rotatably connected on the crossbeam 1; one end of the first piston type reciprocating mechanism 4 is hinged with crossbeam 1, and the other end is hinged with bottom mold grabber 3; the crossbeam 1 is provided with positioning card 14 for positioning the pipe mold, Next to each bottom mold grab hook 3 on the beam 1 is provided with a limit baffle plate 15 for limiting the bottom mold grab hook 3 rotation termination position, 4 cover mold grab hooks 2 and 4 bottom mold grab hooks 3 on the beam 1 The position from left to right is bottom mold grab hook 3, cover mold grab hook 2, bottom mold grab hook 3, cover mold grab hook 2, cover mold grab hook 2, bottom mold grab hook 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com