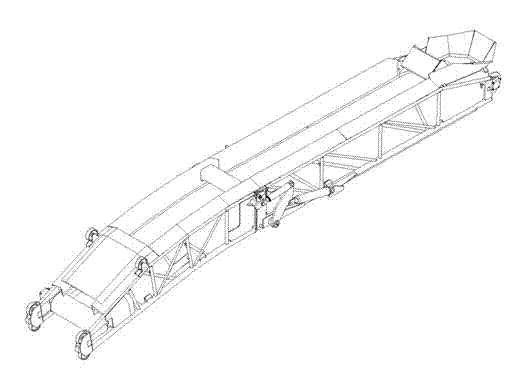

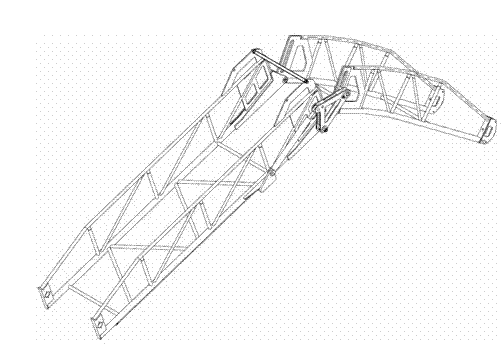

Single-oil-cylinder folding mechanism for milling machine conveying frame

A technology of folding mechanism and single oil cylinder, applied in roads, road repairs, roads, etc., can solve the problems of high cost, difficult installation, complex structure, etc., and achieve the effects of low manufacturing cost, convenient maintenance, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

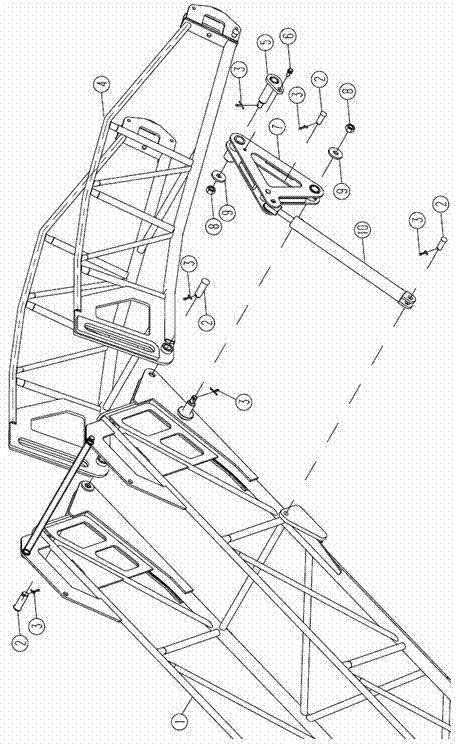

[0015] as attached image 3 As shown, the present invention comprises mutually hinged left steel frame 1, right steel frame 4, and described left steel frame 1 is hinged with a hinge point in the triangular support 7 that has three hinge points, and described triangular support 7 additionally Two hinge points respectively hinge the oil cylinder 10 and the right steel frame 4; one end of the oil cylinder 10 is hinged with a hinge point in the triangular bracket 7, and the other end is hinged with the left steel frame 1; Groove, the chute inner edge is the slide rail that cooperates with groove pin 5, and the groove pin 5 of the hinge of triangular support 7 is stuck in the chute and moves along the chute.

[0016] Described triangular support 7 is positioned at the side of feeding frame, is hinged with the side of left steel frame 1, right steel frame 4.

[0017] The left steel frame 1 and the right steel frame 4 are connected together through the first pin shaft 2 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com