Method for fixedly installing and leveling base of metal upright column of bridge guardrail

A technology for guardrails and bridges, used in bridges, bridge parts, bridge construction and other directions, can solve the problems of low construction speed, waste of manpower, material resources and time, installation and fixation, etc., to achieve high construction speed and quality, easy operation process. , the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

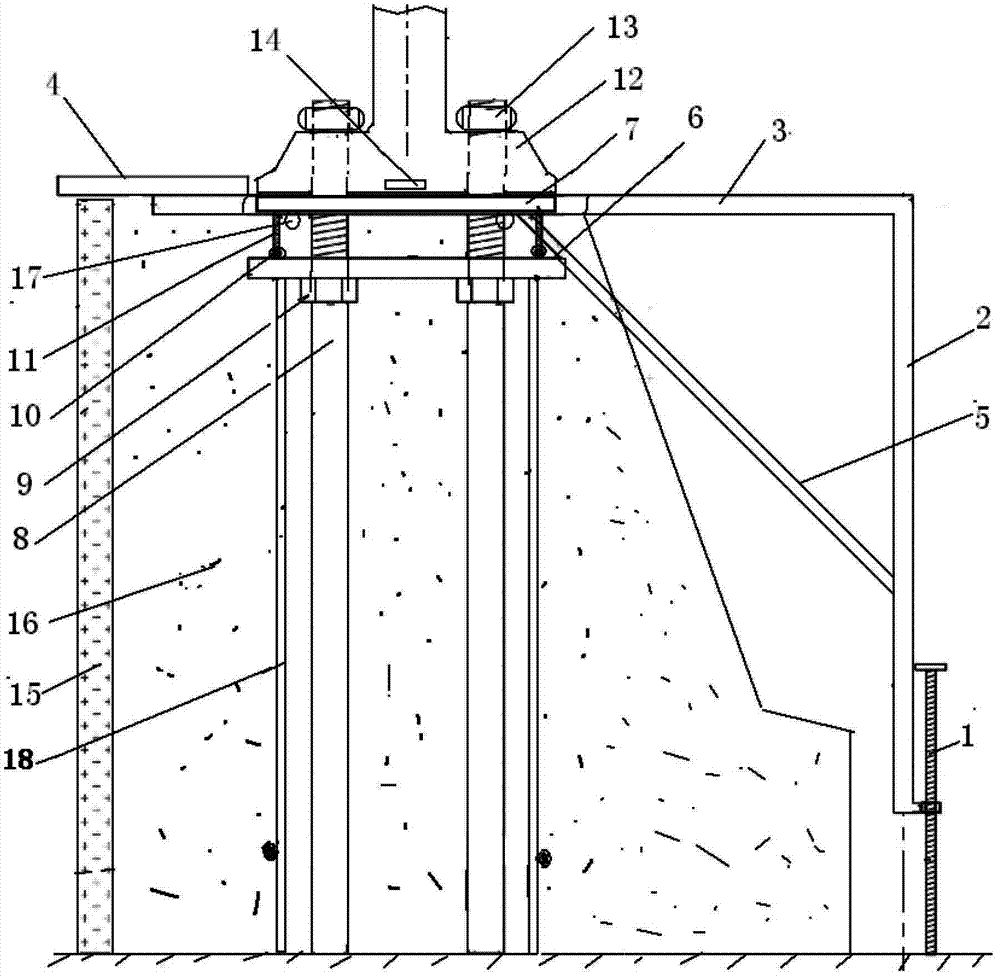

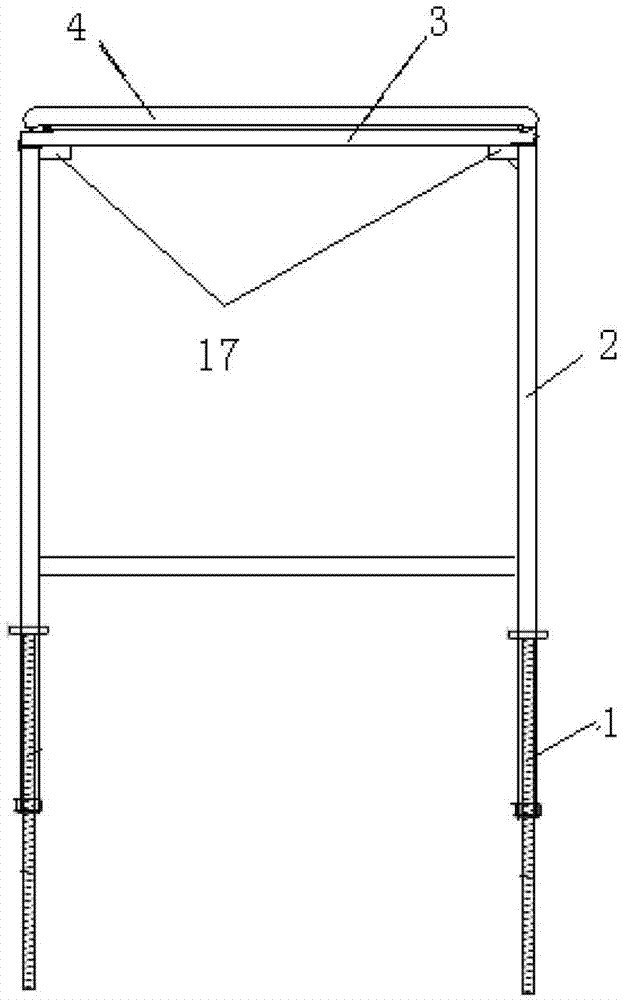

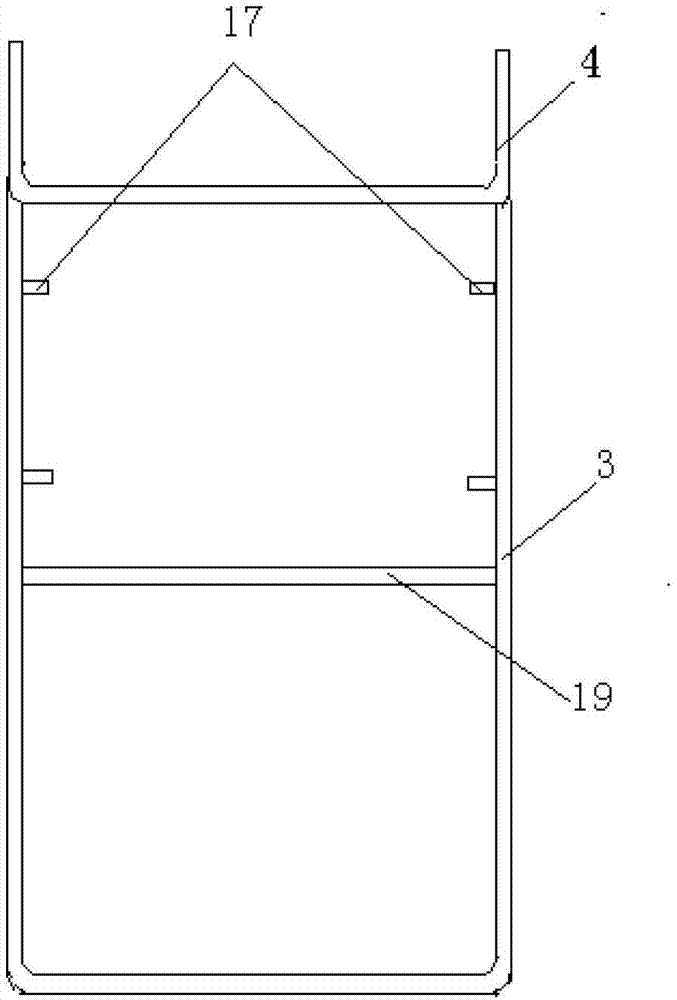

[0020] With reference to the accompanying drawings, the present invention will be described in further detail.

[0021] A method for installing, fixing and leveling the metal column base of a bridge guardrail, the following steps are taken:

[0022] The first step: first make a leveling device; the structure of the leveling device see Figure 1-3 , it is a right angle frame formed by fixed connection of a vertical side frame 2 and a horizontal top frame 3; Flat bolt 1; the top frame 3 is an open frame, that is to say the end of the top frame 3 is open, and two cross bars of the top frame 3 are provided with a reinforcing longitudinal bar 19 (see image 3 ), between the end of the top frame 3 and the reinforcing longitudinal bar 19, two sections of supporting steel bars protruding inward are respectively provided on the lower bottom surface on both sides of the top frame cross bar as the supporting claws 17, and the four supporting claws 17 form a horizontal support surface; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com