Prefabricating assembling type cold molding steel floor system and construction method thereof

A technology of prefabricated assembly and section steel, applied in the direction of floors, building components, buildings, etc., can solve the problems of small self-weight and low cost, achieve the effect of light self-weight, reduce cost, and ensure integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

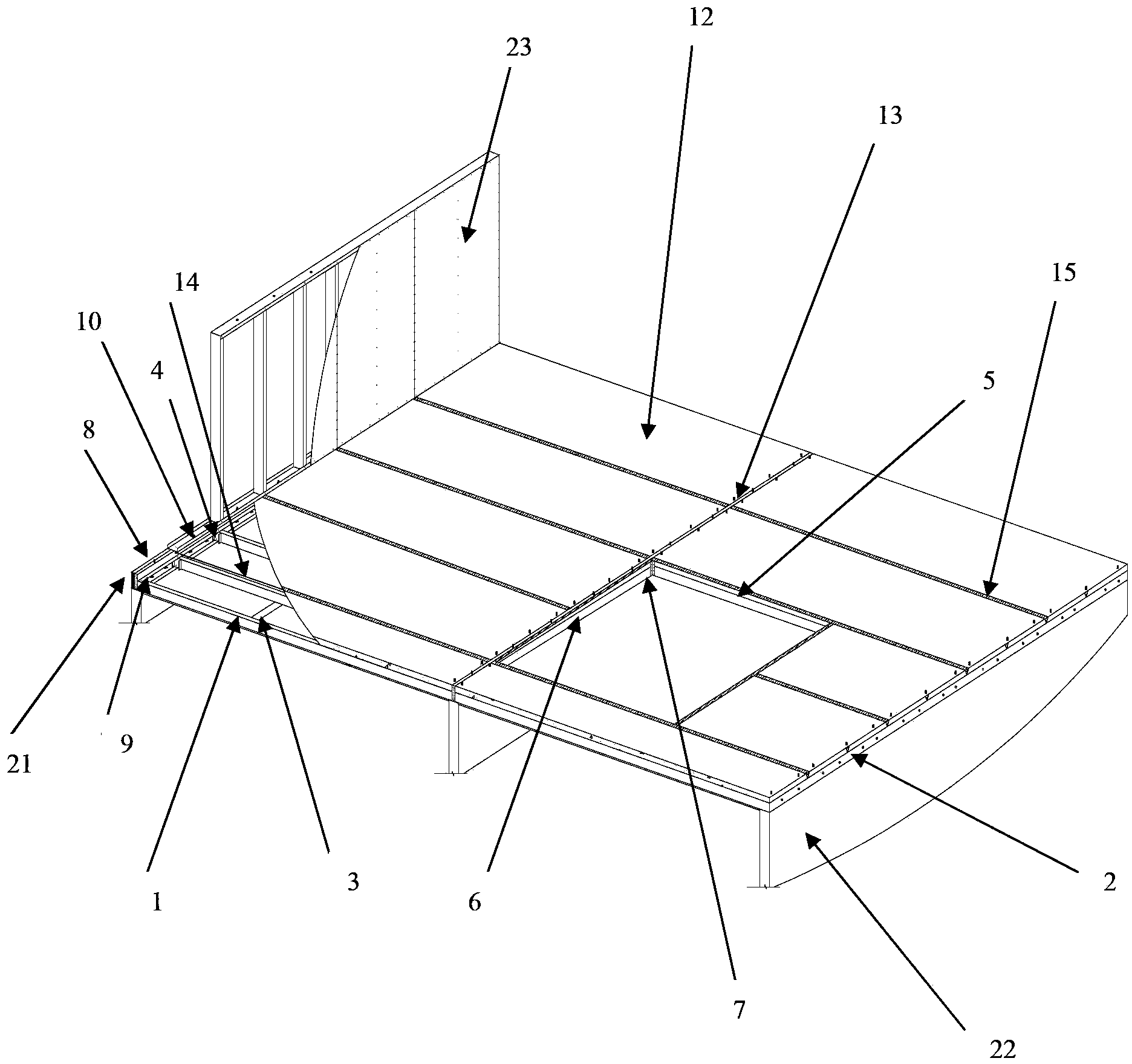

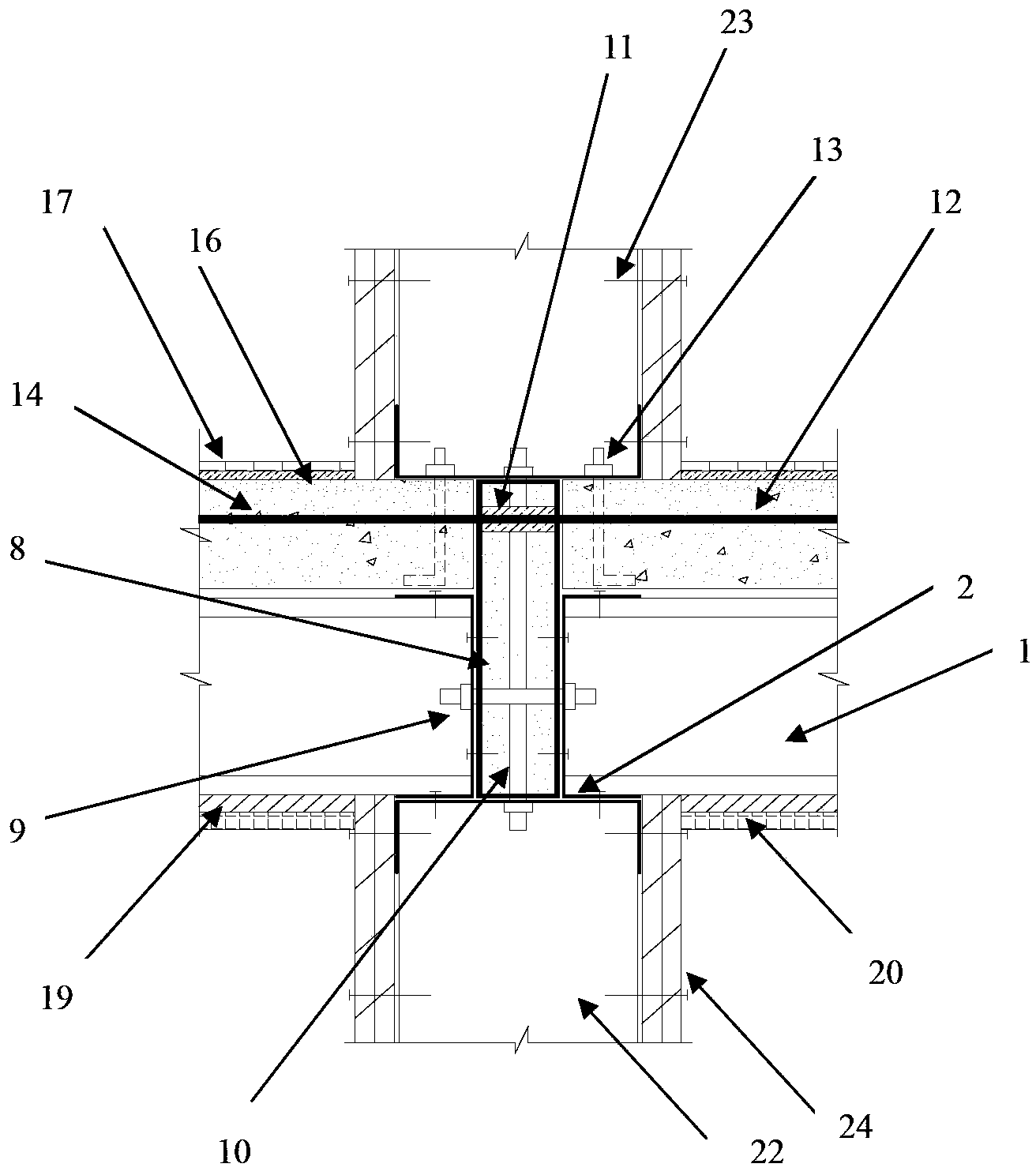

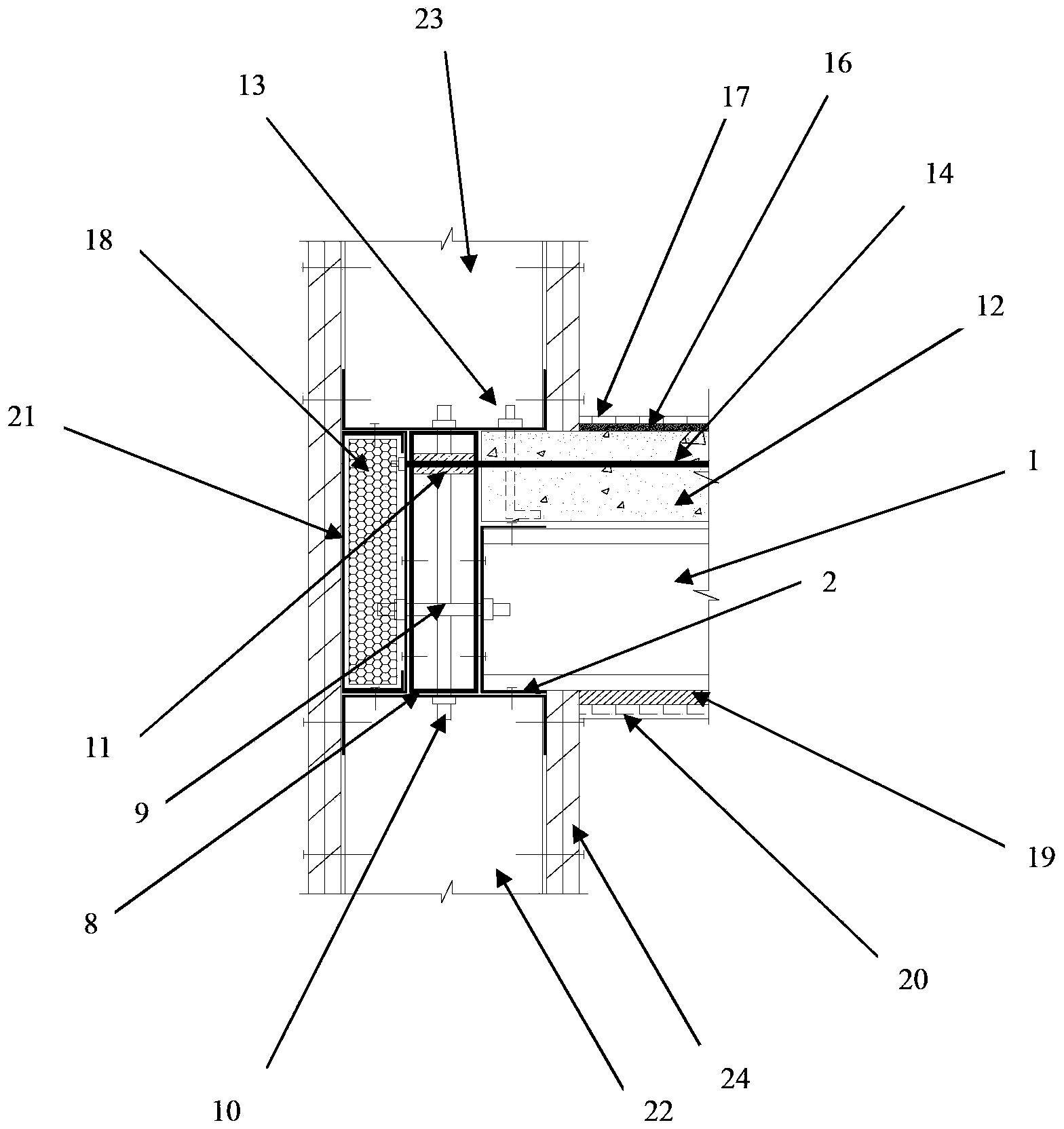

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] like Figure 1 to Figure 13As shown, a prefabricated assembled cold-formed steel floor of the present invention includes a keel unit, a rectangular steel tube concrete tension beam 8, a lightweight concrete slab 12, a long steel bar 14, a thermal insulation material layer 18, and a lower wall 22 And upper wall body 23. The upper wall 23 is located above the lower wall 22 , and the upper wall 23 is opposite to the lower wall 22 . The rectangular steel tube concrete tension beam 8 is located between the lower wall 22 and the upper wall 23 , and the rectangular steel tube concrete tension beam 8 is fixedly connected to the lower wall 22 and the upper wall 23 respectively. For example, the vertical screw rod 10 is used to connect the rectangular steel tube concrete tension beam 8 with the lower wall body 22 and the upper layer wall body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com