A cold-formed thin-walled steel composite floor and its modular prefabricated assembly method

A cold-formed thin-walled steel and cold-formed thin-walled technology, which is applied to floors, buildings, and building components, can solve problems such as large floor thicknesses, and achieve the effects of reduced self-weight, simple procedures, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

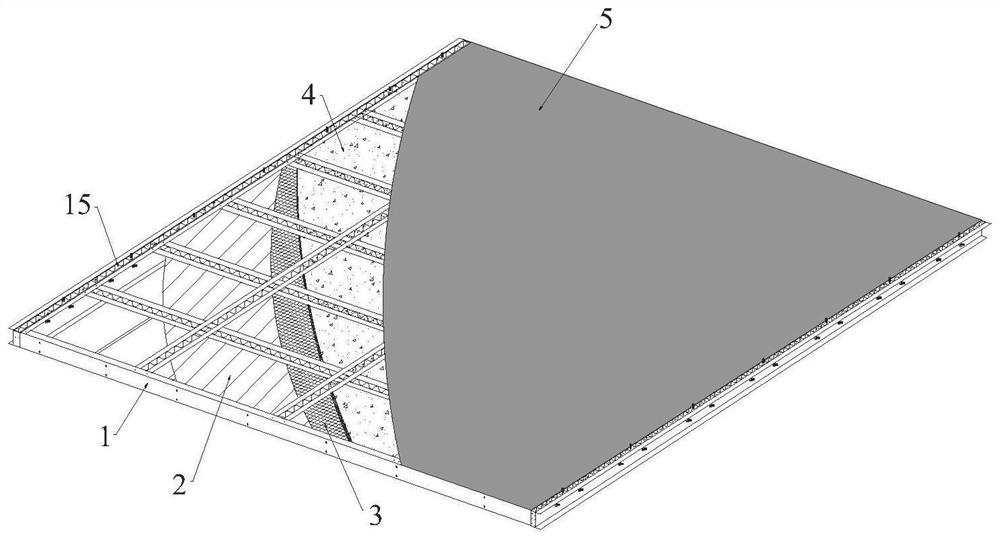

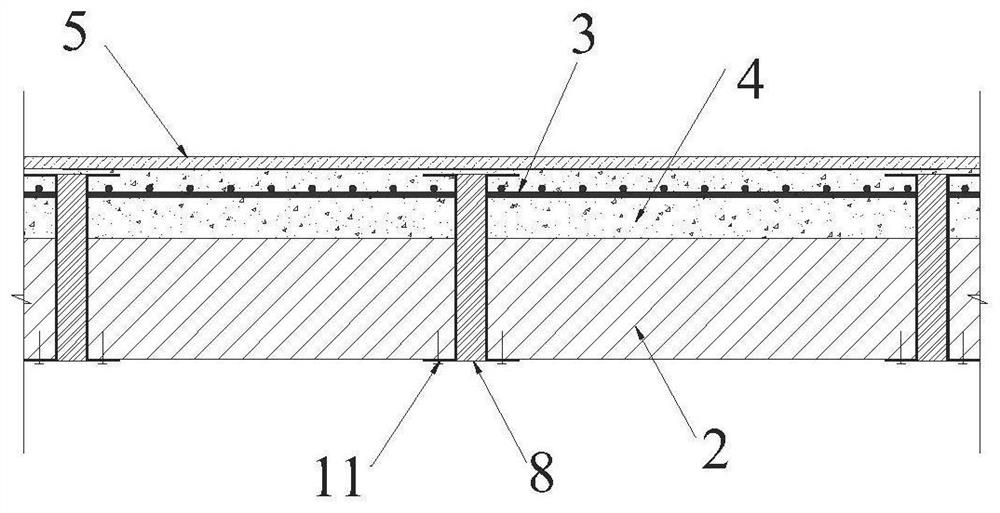

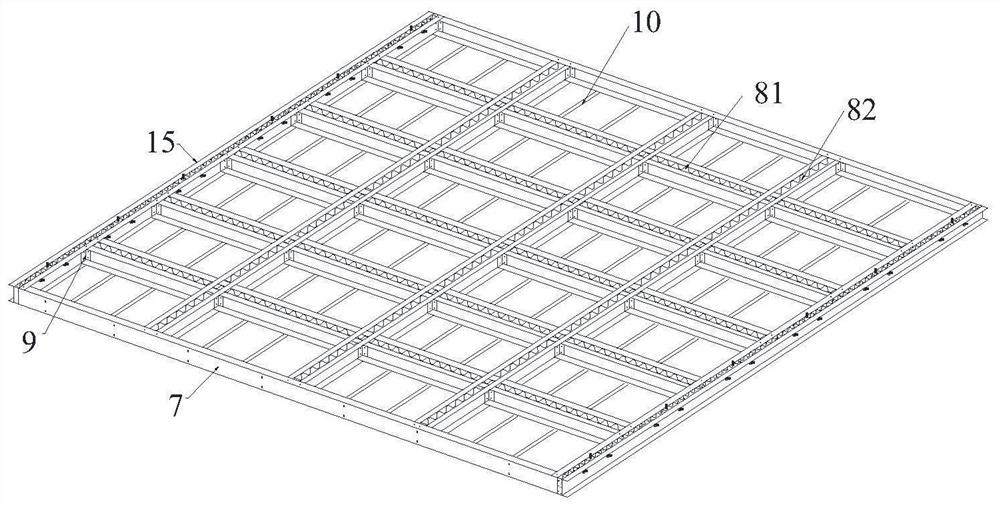

[0039] Such as figure 1 with figure 2 As shown, the composite floor of the present invention includes cold-formed thin-walled steel skeleton 1, autoclaved aerated concrete slab 2, steel mesh 3, lightweight concrete 4 and facing layer 5, and cold-formed thin-walled steel skeleton 1 passes through the process. The font-shaped rib beams 8 form a grid shape, and the autoclaved aerated concrete slab 2 is embedded between the adjacent I-shaped rib beams 8 of the cold-formed thin-walled steel skeleton 1, and the autoclaved aerated concrete slab 2 and the I-shaped rib beams The lower flange of 8 is fixedly connected by self-tapping screws 11; the reinforcement mesh 3 is located above the autoclaved aerated concrete slab 2, and is integrated with the lightweight concrete 4; above, and connected to the upper flange of the I-shaped rib beam 8 by self-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com