Variable-pressure gas release braking method and variable-pressure gas release brake for implementing same

A brake and oil draining technology, which is applied to non-mechanical actuated valves, engine components, engine control, etc., can solve the problems of slow brake response speed, unsatisfactory braking effect, low braking power, etc., and achieve braking effect Good, reasonable and reliable product structure design, high braking power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

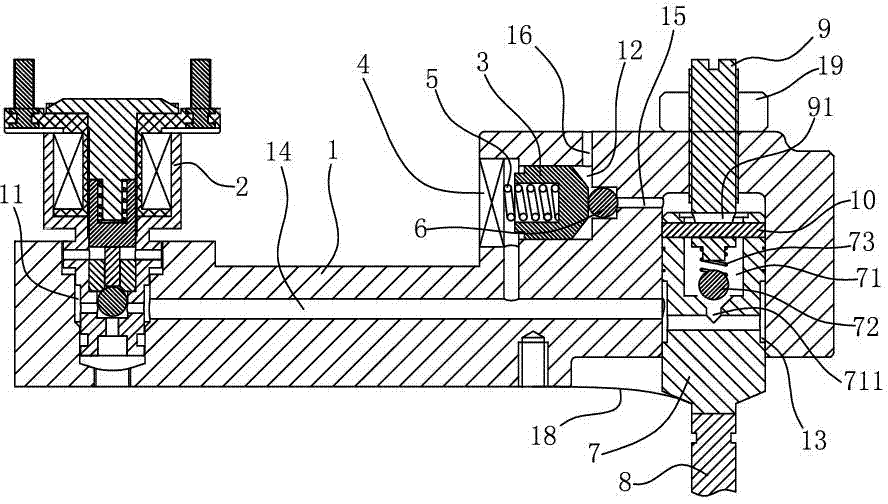

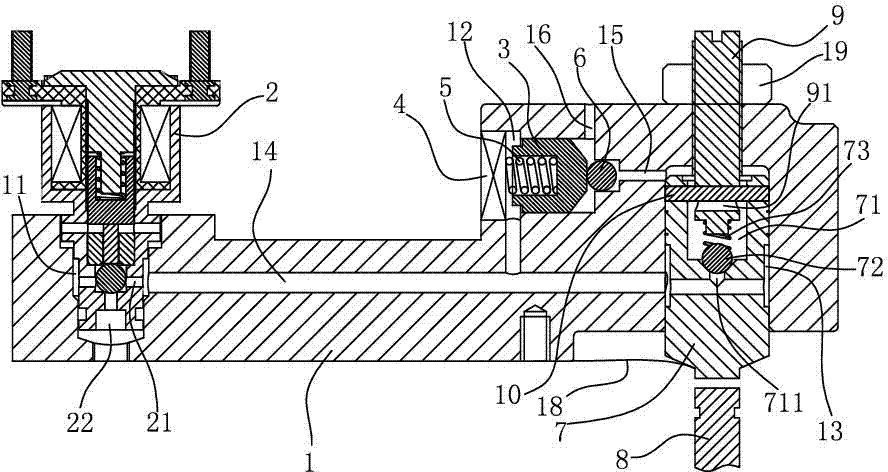

[0029] Example: see figure 1 with figure 2 , The present invention is a pressure-variable vented braking method, which includes the following steps:

[0030] (1) A brake housing 1 is provided. A first cavity 11, a second cavity 12, and a third cavity 13 are arranged on the brake housing 1 in sequence. An oil inlet 14 is connected between the middle part and the first cavity 11, an oil drain 15 is connected between the top of the third cavity 13 and the second cavity 12, and the rear part of the second cavity 12 is connected to the inlet The oil passage 14 is connected, and an oil drain 16 is provided at the front of the second cavity 12;

[0031] (2) Fix a solenoid valve 2 in the first cavity 11, and the oil outlet 21 on the solenoid valve is connected to the oil inlet 14;

[0032] (3) A slider 3 is slidably arranged in the second cavity 12 back and forth, and a plug 4 is used to seal the rear end of the second cavity 12, and a second cavity 12 is connected between the plug 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com