Split vacuum pipe type solar water heater

A technology of solar water heaters and vacuum tubes, which is applied to solar collectors, solar collectors using working fluids, and solar thermal energy. Simple and reasonable, low manufacturing cost, and the effect of reducing scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

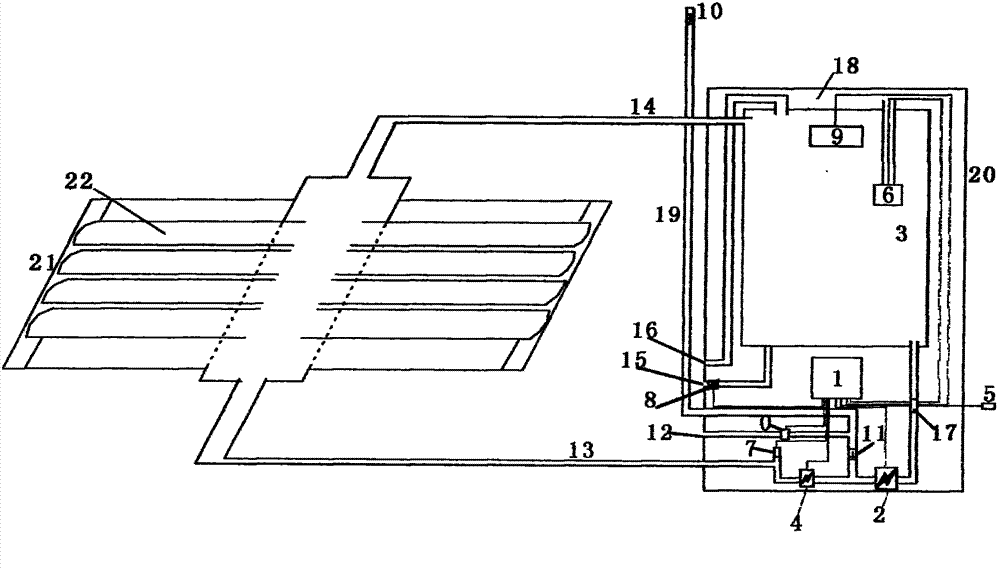

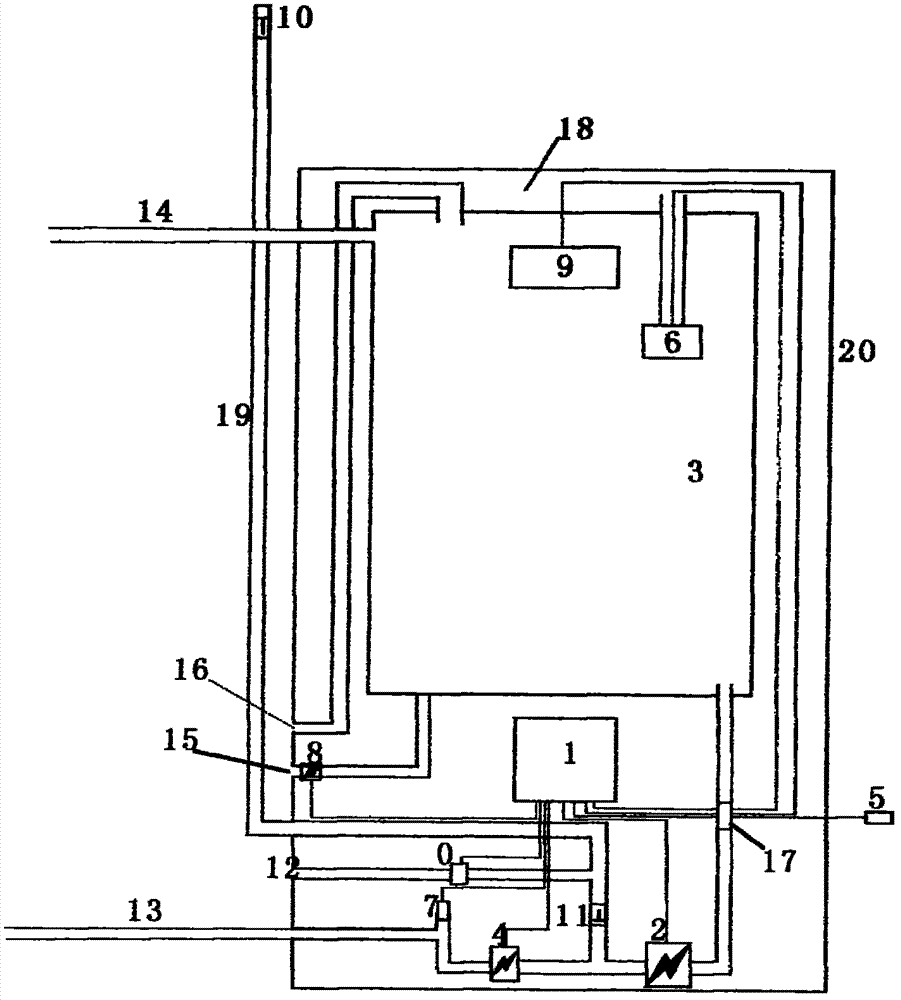

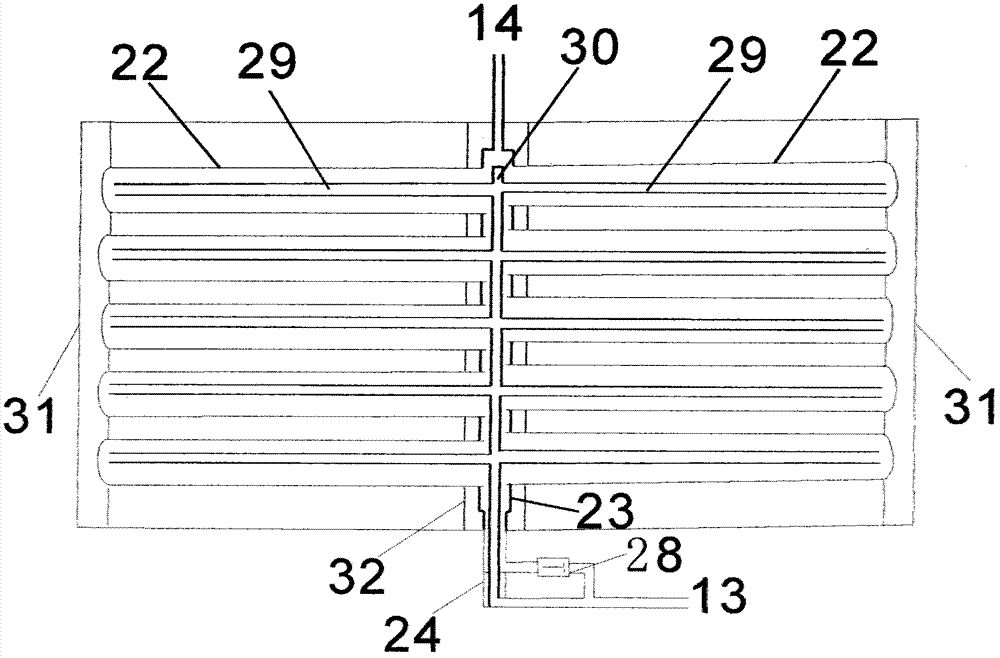

[0036] like figure 1 , 2 In the embodiment shown in: the vacuum tube type split solar water heater, it includes a non-pressure-bearing inner unit 20 and a vacuum tube type heat collecting outer unit 21, the inner unit 20 is composed of the integrator 1, and the light connected in parallel with it Sensor 5, two-way circulation pump 2, multiple control valves 4, 8, multiple water level sensors 6, 7, display panel 9, boost sensor 0, and multiple one-way valves 10, 11, filter valve 17, exhaust Air port 16, multi-channel water inlet and outlet pipelines 13, 14, circulation pipelines 12, 15, automatic pressurization pipeline 19, insulation layer 18 and water tank 3, etc., and are matched with the heat collecting external unit to form the whole machine and the whole machine. Operating system; it detects the external light through the optical sensor 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com