Energy-saving and dehumidifying system of screw refrigerator

A technology of screw type and refrigerator, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of large consumption, high operating costs, energy waste, etc., and achieve reduced installed capacity, improved energy efficiency ratio, and increased cooling capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

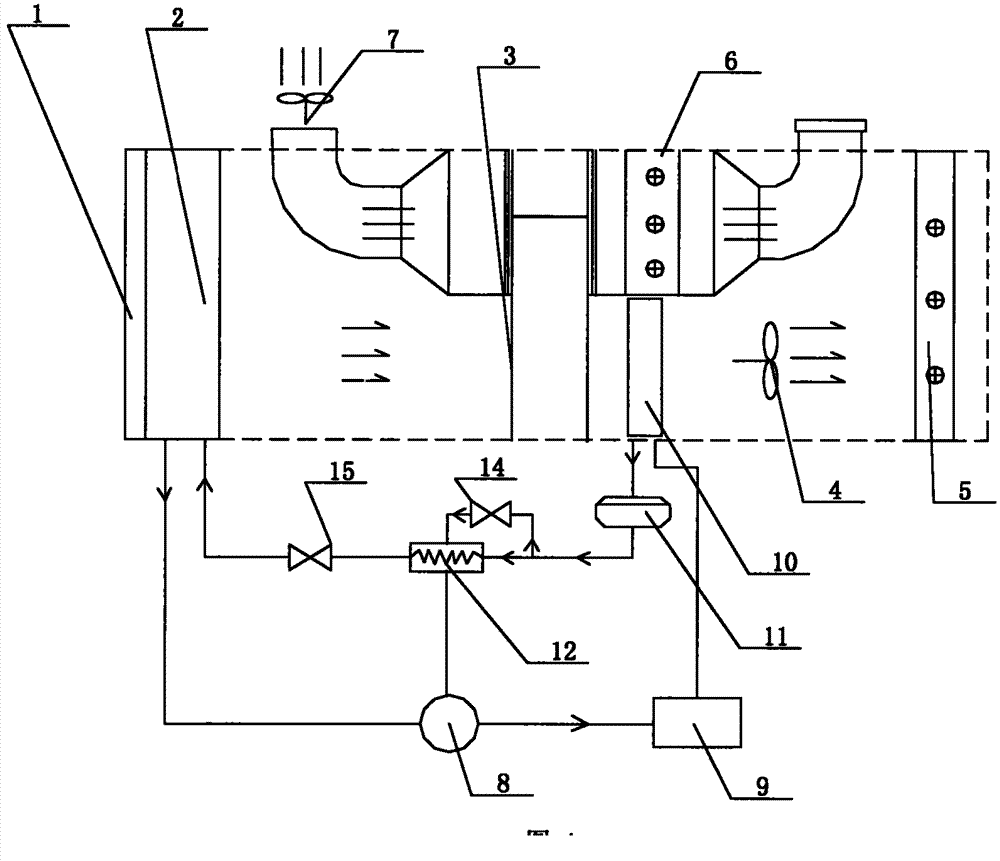

[0012] see figure 1 , the specific embodiment adopts the following technical solutions: it includes filter 1, evaporator 2, dehumidification runner 3, main fan 4, rear heater 5, regeneration heater 6, regeneration fan 7, and it also includes screw refrigeration Compressor 8, condensing agent 9, subcooler 10, liquid reservoir 11, economizer 12, first throttle valve 14 and second throttle valve 15; A screw refrigeration compressor 8, a condensing agent 9, a subcooler 10, a liquid reservoir 11, a first throttle valve 14, and a second throttle valve 15 are sequentially connected to the circulating road at one end of the evaporator 10 and the evaporator 2, and the liquid storage An economizer 12 is also arranged between the junction of the device 11 and the second throttle valve 15 .

[0013] Both ends of the economizer 12 are connected to the first throttle valve 14 and the screw refrigeration compressor 8 respectively.

[0014] A quarter of the upper end of the dehumidification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com