Low temperature test device of seal cover nuts

A low-temperature test and cap screw technology, which is applied in the field of mechanical parts testing, can solve the problem that the testing equipment for the tightness of nut connections has not been launched on the market, and achieves the effect of unlimited installation position, simple principle and good device sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

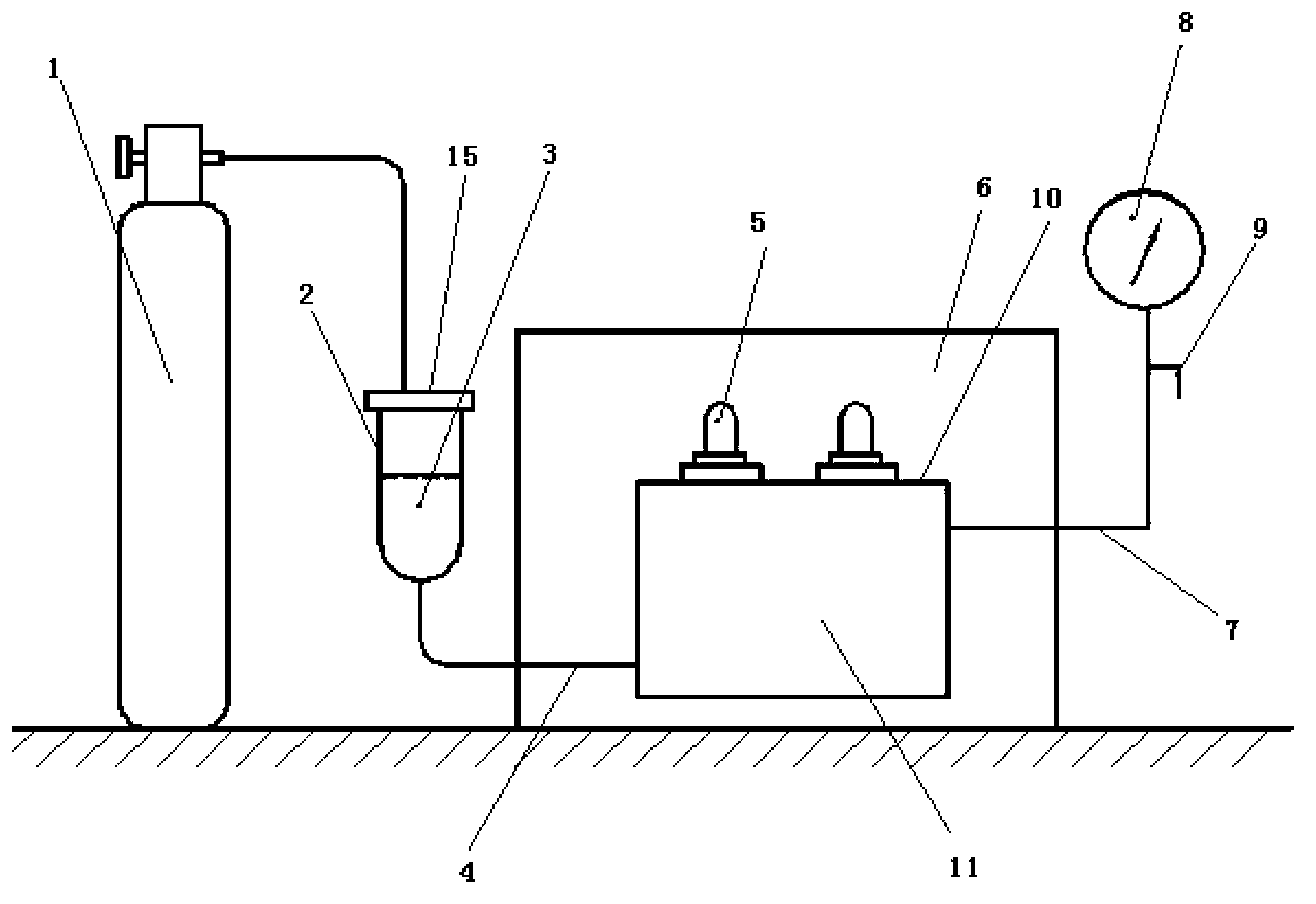

[0015] Such as figure 1 , figure 2 As shown, the present invention provides a low-temperature test device for sealing cover nuts, including an argon gas bottle 1, an oil cylinder 2, a low-temperature box 6, a test tooling 11, a pressure gauge 8 and an air release valve 9, an argon gas bottle 1, an oil cylinder 2, Both the pressure gauge 8 and the air release valve 9 are placed outside the low temperature box 6, and the test tooling 11 is placed inside the low temperature box 6.

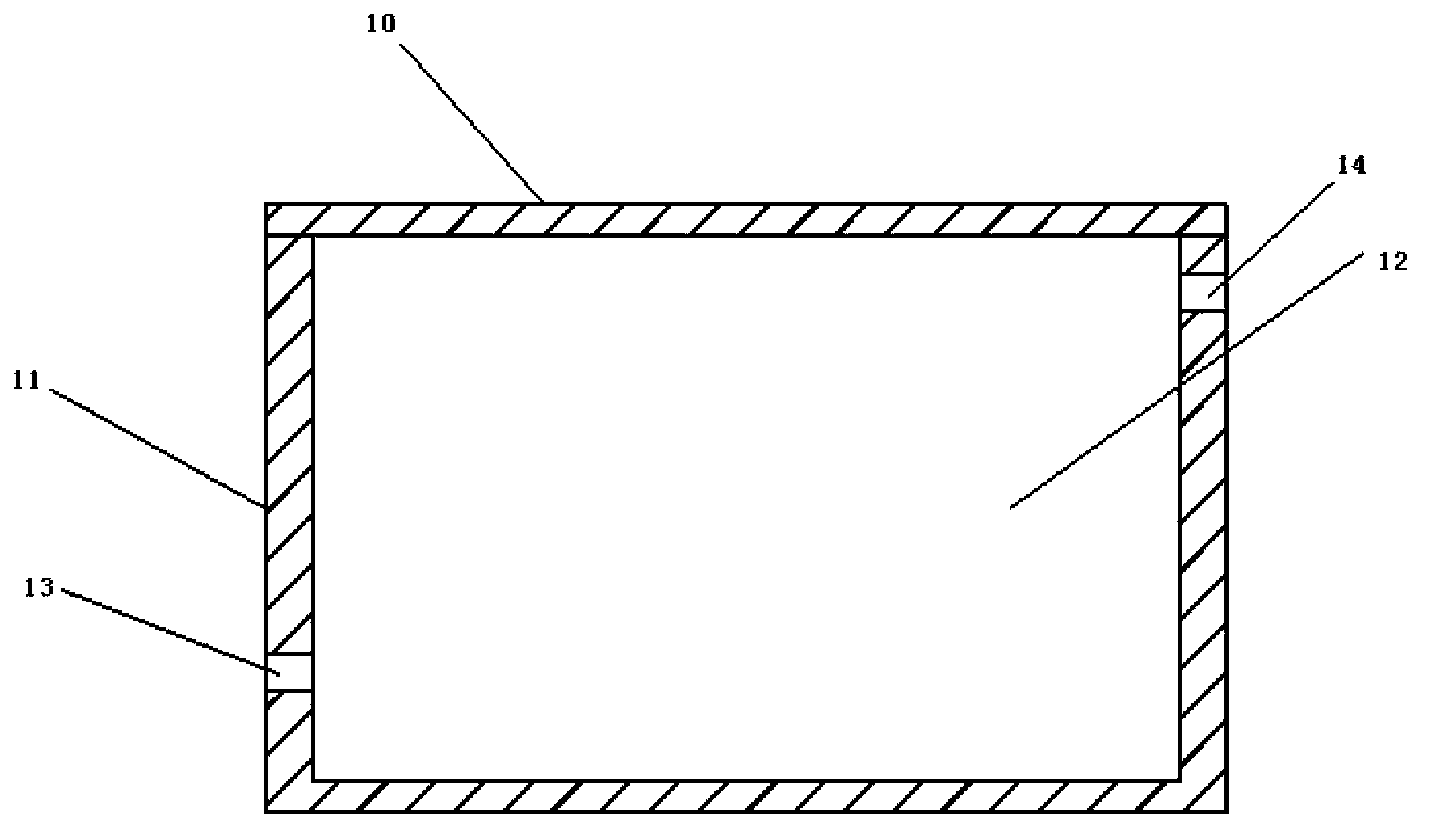

[0016] The test tooling includes a cover plate 10 and a box body with a cavity 12. The side of the box body has an oil inlet 13 and an air outlet 14 communicating with the cavity 12. The cover plate 10 has several holes for fixing the sealed cover to be tested. The through hole of the nut 5, the cover plate 10 and the cavity 12 are hermetically connected.

[0017] The argon cylinder 1 is connected with the oil tank 2, and the argon gas is delivered to the oil tank 2. The oil tank 2 is filled with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com