Method for determining gas permeability coefficient of concrete

A technology of gas permeation and gas permeability, which is applied in the field of construction engineering, can solve the problems of large errors and no consideration of the gas slip effect, and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

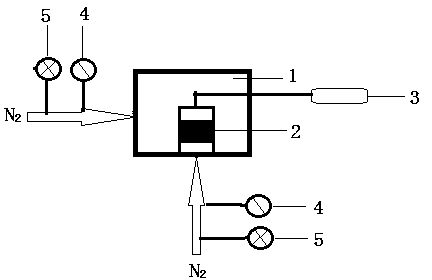

[0025] Example 1: After sealing the side of the concrete specimen (with a size of Φ100mm×50mm) formed and maintained for 28 days with epoxy resin, place it in the test tank of the gas permeability test device, fix it, and then, in the figure 1 Enter N into the test tank in the left direction 2 , adjust the outlet air pressure P through the pressure regulator and the pressure gauge 2 0.1N / m 2 . Then enter N on the lower side 2 , and the pressure regulator and pressure gauge to adjust the inlet air pressure P 1 0.3N / m respectively 2 , 0.5N / m 2 , 0.7N / m 2 , 0.9N / m 2 , 1.1N / m 2 . After waiting for the gas flow to be constant, measure the inlet air pressure P through the flowmeter 1 0.3N / m respectively 2 , 0.5N / m 2 , 0.7N / m 2 , 0.9N / m 2 , 1.1N / m 2 When, the outlet gas flow rate Q 2 7.9×10 -13 m 3 / s, 1.5×10 -12 m 3 / s, 2.5×10 -12 m 3 / s, 3.7×10 -12 m 3 / s, 4.9×10 -12 m 3 / s. Put μ=17.58×10 -6 Ns / m 2 、L=0.05m、P 2 =0.1N / m 2 ,P 1 , Q2 and A=7.85×10 -3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com