A plug-in method for making circuit boards of microwave instruments intelligent

A microwave instrument and smart plug-in technology, applied in the field of intelligence, can solve the problems of uneven circuit board software, long life cycle of microwave instrument products, and difficulty in guaranteeing later software, so as to facilitate mass production and after-sales maintenance, and facilitate Batch debugging and after-sales maintenance, convenient independent upgrade and improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

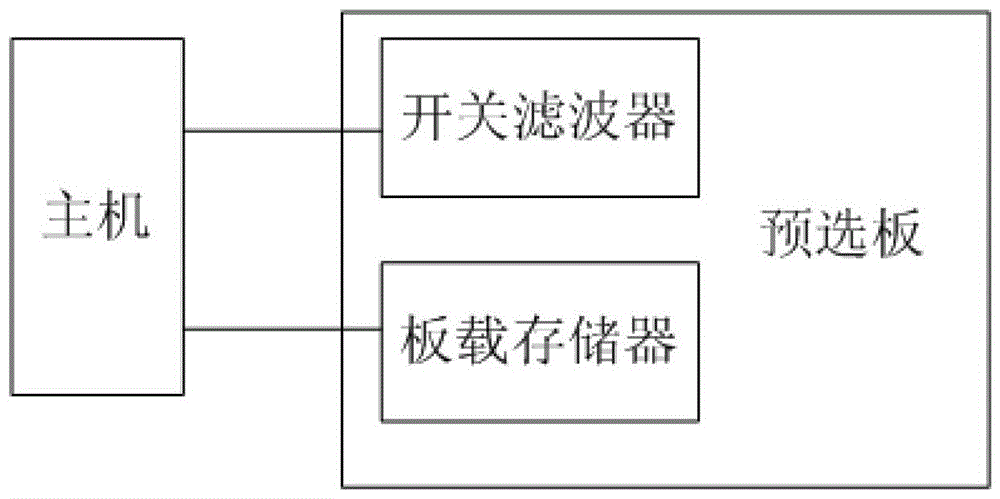

[0027] In the following, a preferred embodiment of the present invention will be given by taking a functional circuit board in a receiver of a certain model - the signal preselection board as an example, in order to describe the technical solution of the present invention in detail. The signal pre-selection board realizes signal pre-selection filtering in a wide range from 9Hz to 40GHz through the combination of multiple internal filters. The filters of each pre-selection board have different indicators such as bandwidth and frequency due to production and debugging.

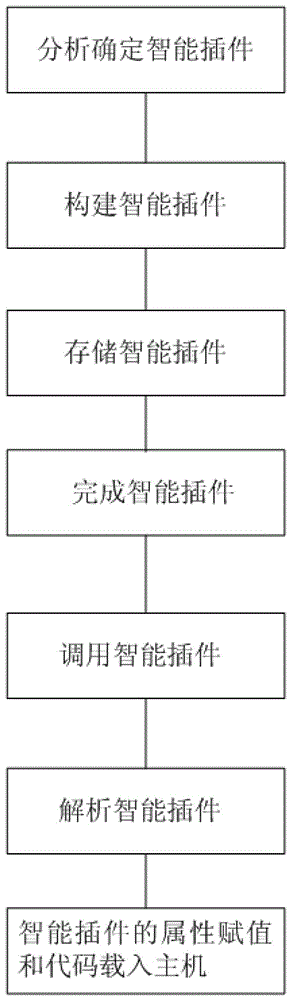

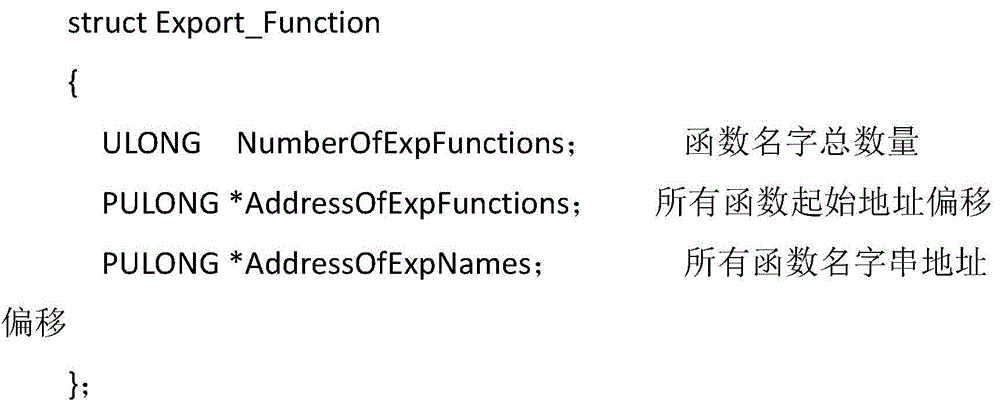

[0028] Such as figure 1 Shown, the plug-in method that the present invention makes microwave instrument circuit board intelligence makes each microwave instrument circuit board have on-board memory, main frame, switch filter, and on-board memory, switch filter are all connected with main frame, and on-board memory uses It is used to store the characteristic attribute data and board-level function code of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com