Self-propelled corn-harvesting straw-bundling combined machine

A combined working machine and self-propelled technology, applied in the direction of balers, harvesters, agricultural machinery and implements, etc., can solve the problems that affect the enthusiasm for recycling straw, increase the operating cost, and increase the impurity rate of straw, so as to increase the income of farmers. , The effect of reducing operating costs and reducing operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

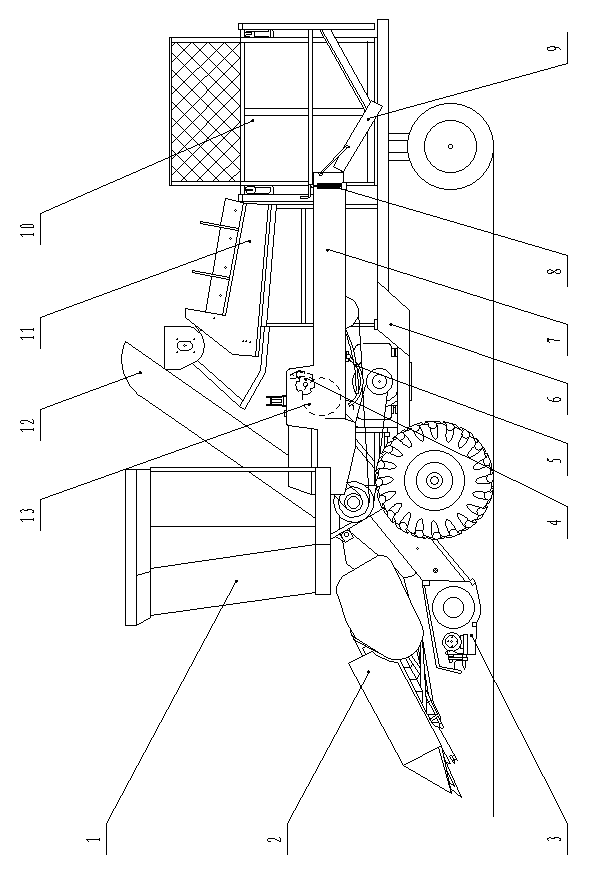

[0021] Such as Figure 1 to Figure 4 As shown: the compound header is installed on the front of the frame 6, the horizontal straw feeding auger 13 is installed on the frame 6, and is located at the rear and lower part of the cab 1, and the straw bundling device 7 is located on the left side of the frame 6; the compound header Including upper cutting platform 2 and lower cutting platform 3, upper cutting platform 2 is located above lower cutting platform 3, lower cutting platform 3 includes reciprocating straw cutting device 14, straw collecting auger 15 and straw conveying device 17, reciprocating straw cutting device 14 is positioned at lower cutting platform 3 front ends, and the back of reciprocating straw cutting device 14 is straw collection auger 15, and the output port of straw collection auger 15 is located in the middle, links to each other with straw delivery device 17.

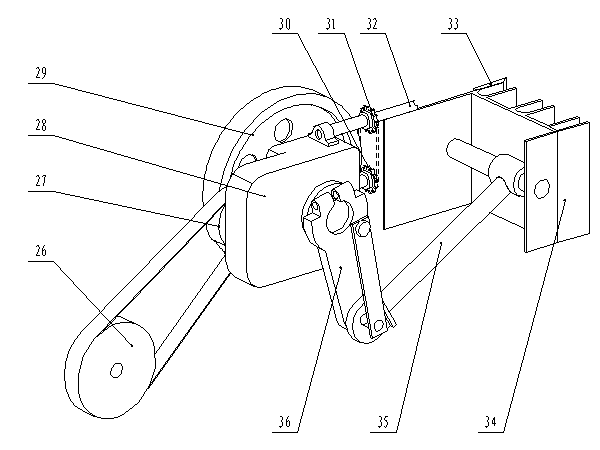

[0022] The straw conveying device 17 is composed of seven feeding rollers located on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com