A kind of pouring method of electrode billet

A casting method and electrode technology are applied in the field of electrode blanks, which can solve the problems of high energy consumption and high cost of consumable electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In this embodiment, one furnace of G20Cr2Ni4A was smelted by electric furnace smelting + LF furnace refining + VD degassing process, and cast with extra-long electrode blanks.

[0038] The mass percentage of chemical composition after LF furnace refining is:

[0039] C0.19%; Si0.27%; Mn0.58%; P0.016%; S0.004%; Cr1.50%; Ni3.47%; Cu0.01%; Al0.062%;

[0040] The rest is Fe and unavoidable impurities.

[0041] When leaving the VD station, the temperature is 1570°C, the bottom blowing argon is stirred weakly for 15 minutes, and the flow rate of argon blowing per minute is 0.5-2.5Nm 3 , subject to the fact that the molten steel is not exposed, and then pouring. Two trays are used for pouring, and each tray is 4 ingot moulds.

[0042] The specific requirements and steps of pouring in this embodiment are as follows:

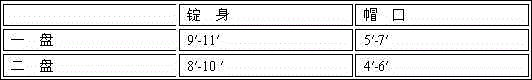

[0043] The specifications of the ingot mold are as follows:

[0044] The inner diameter of the upper mouth is 556; the inner diameter of the lower mouth is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com