Vertical centerless grinder

A centerless grinding machine, vertical technology, applied in the direction of grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve the problems of complex adjustment, low grinding efficiency of cylindrical grinders, and inability to realize centerless grinders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

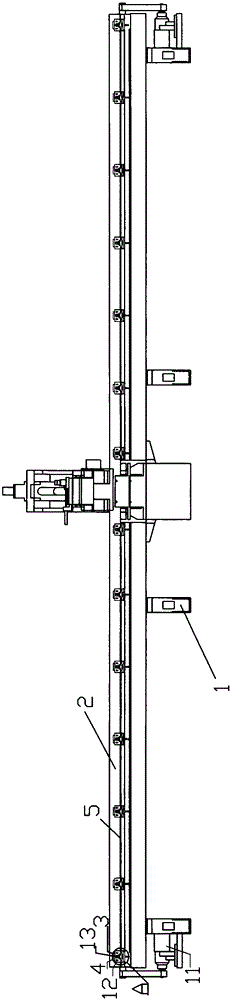

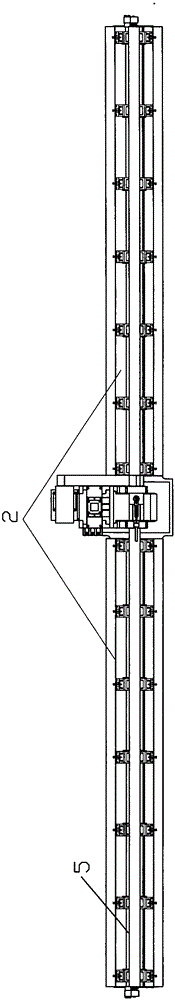

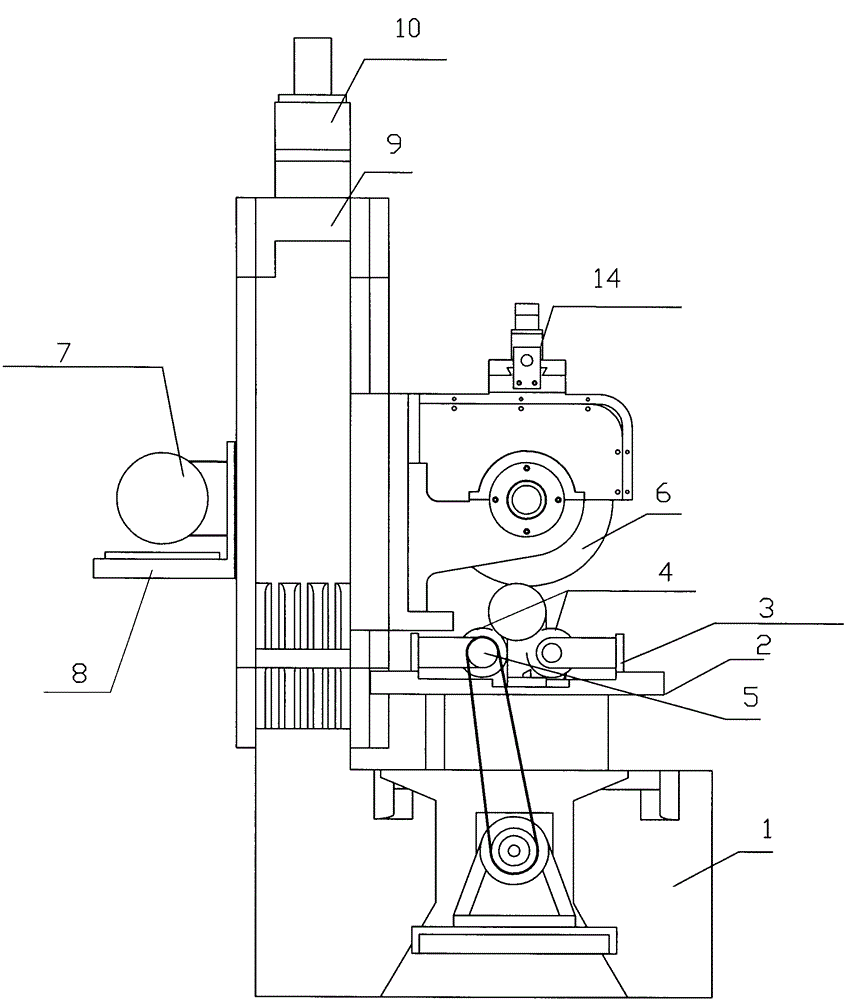

[0021] Embodiment 1: refer to Figure 1 to Figure 4 , a vertical centerless grinder, comprising a frame, a feeding frame, a roller, a roller, a grinding wheel, a grinding wheel transmission motor, a grinding wheel adjustment device, a grinding wheel support, a column, a servo motor, and a rolling wheel transmission motor; wherein:

[0022] The feeding frame is extended from left to right, supported by several rows of racks below, and there are two extending rollers on the top. Each roller drives several rollers. The bottom of the rollers is movably connected to the feeding frame. The cardan shaft driving the roller makes the roller rotate;

[0023] The column is located in the middle of the feeding rack and protrudes upwards. The top of the column is a servo motor. The grinding wheel support is installed on the column. The grinding wheel drive motor is installed on the grinding wheel support. The grinding wheel support can move up and down on the column through the servo motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com