Work platform capable of turning at multiple angles

A working platform and multi-angle technology, applied in the field of tooling and fixture manufacturing, can solve the problems of increasing auxiliary operation time, difficulty in ensuring assembly quality, and high labor costs, so as to reduce auxiliary operation time, improve production efficiency and product quality, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

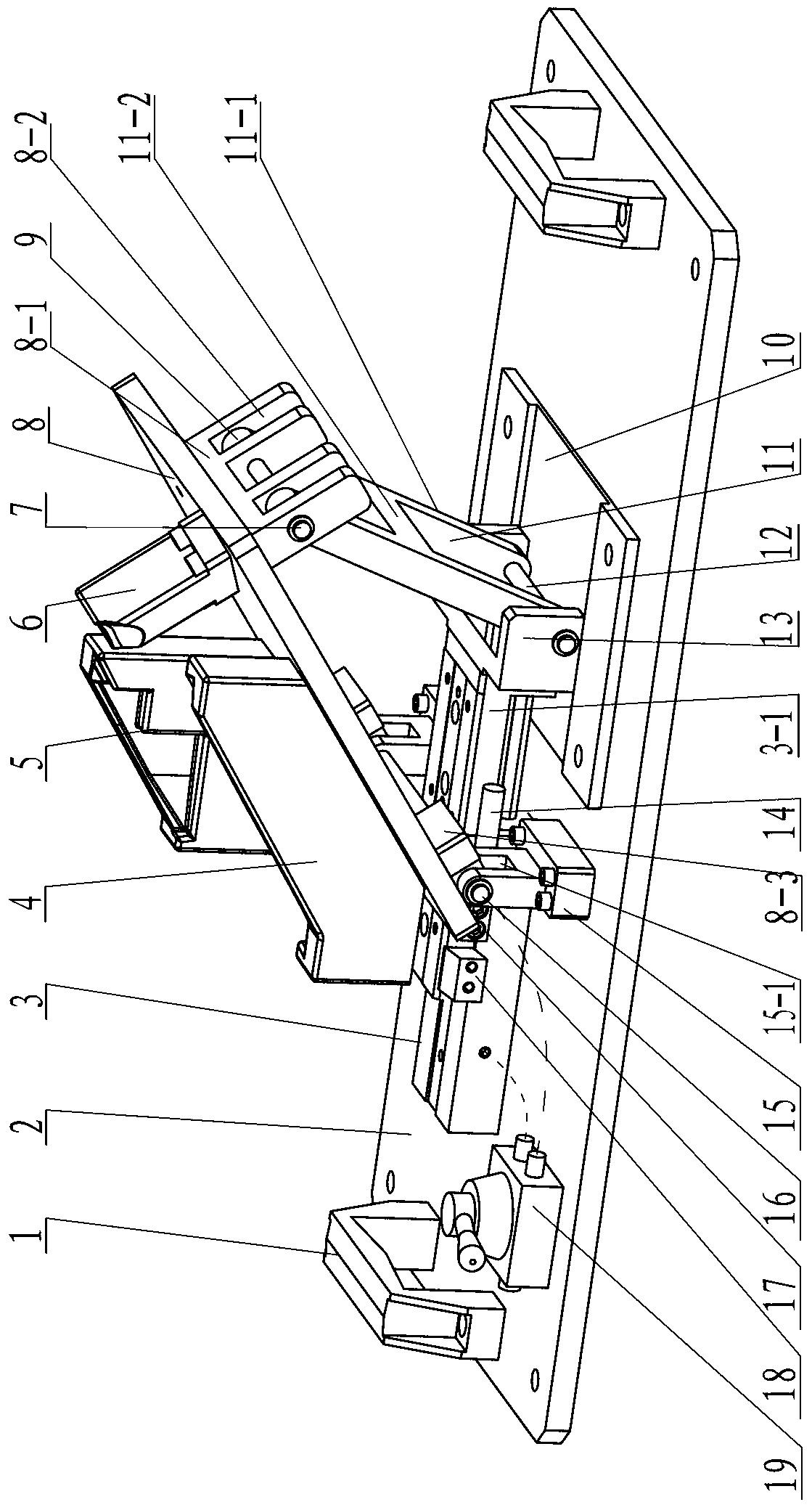

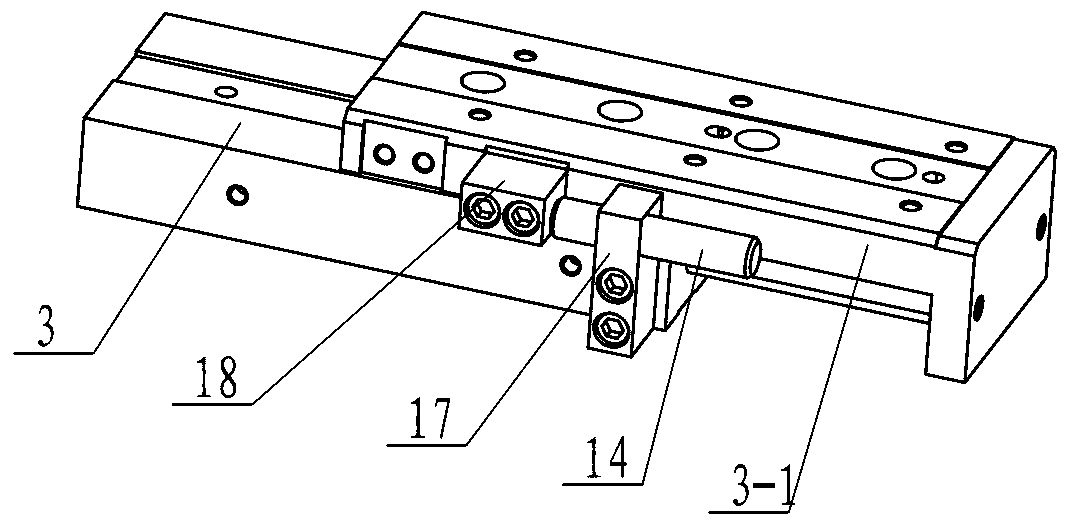

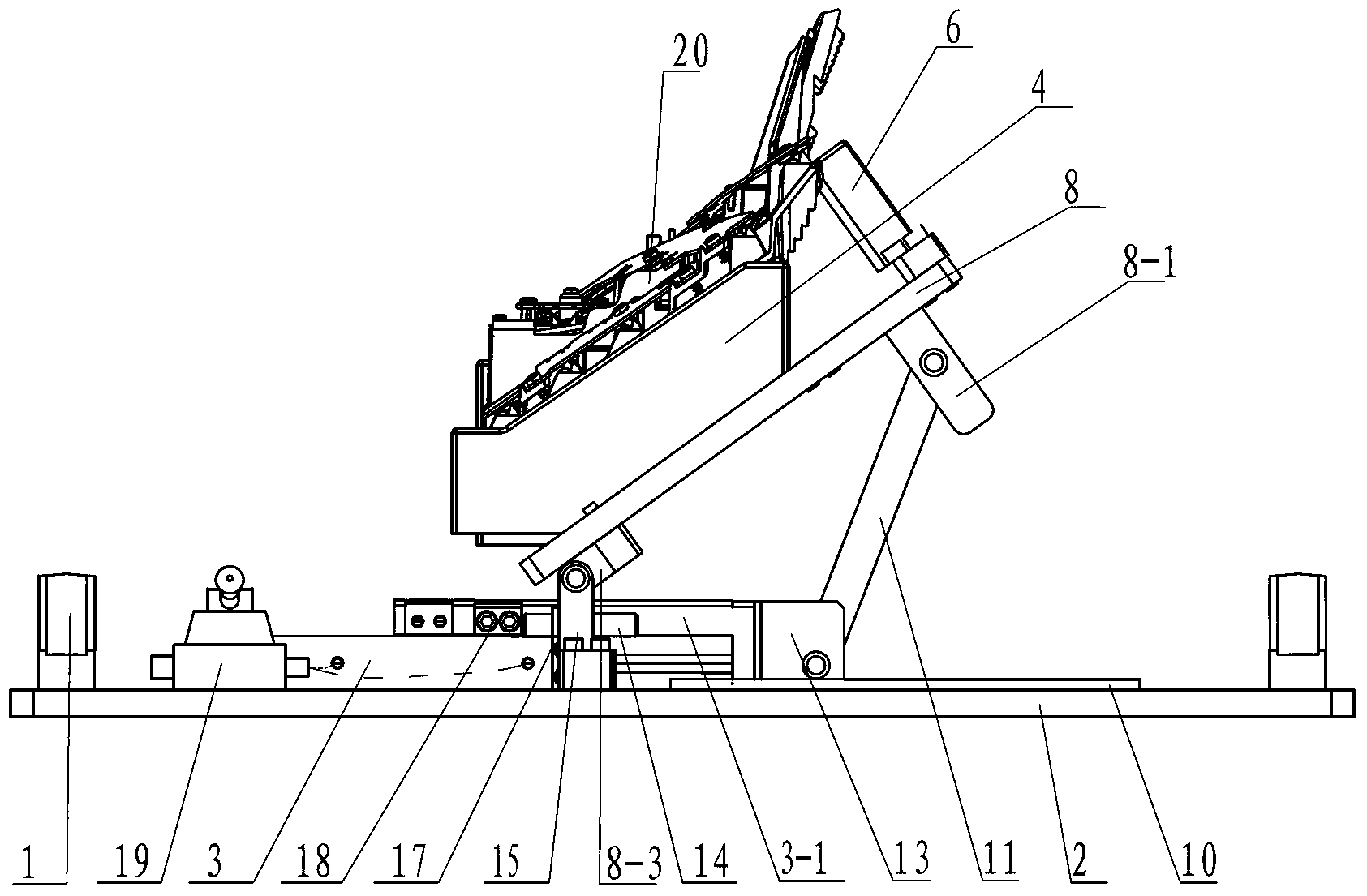

[0012] See Figure 1~4 As shown, the multi-angle turning work platform of the present invention includes a base plate 2, two hinged seats 15, a slide cylinder 3, a slider 13, a connecting rod 11 and a mounting plate 8, the slide cylinder 3 is installed on the base 2, and the slide The sliding table 3-1 on the table cylinder 3 is connected with the slider 13, and the pneumatic switch 19 installed on the bottom plate 2 communicates with the working chamber of the sliding table cylinder 3 through the air pipe, and the sliding table cylinder 3 is controlled by the pneumatic switch 19. For the moving direction of the table 3-1, the slide table cylinder 3 of the present invention is provided with a speed regulating valve, through which the turning speed of the mounting plate 8 is controlled by the speed regulating valve, so that it can work safely and reliably.

[0013] See figure 1 , 3 , 4, the two hinged seats 15 installed on the bottom plate 2 of the present invention are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com