Handy stamp-pad ink feeder of stamping machine

A stamping machine and automatic stamping machine technology, applied in printing, stamping, etc., can solve the problems of frequent replacement, achieve the effects of reducing volatilization, prolonging the use time, and ensuring the quality of stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

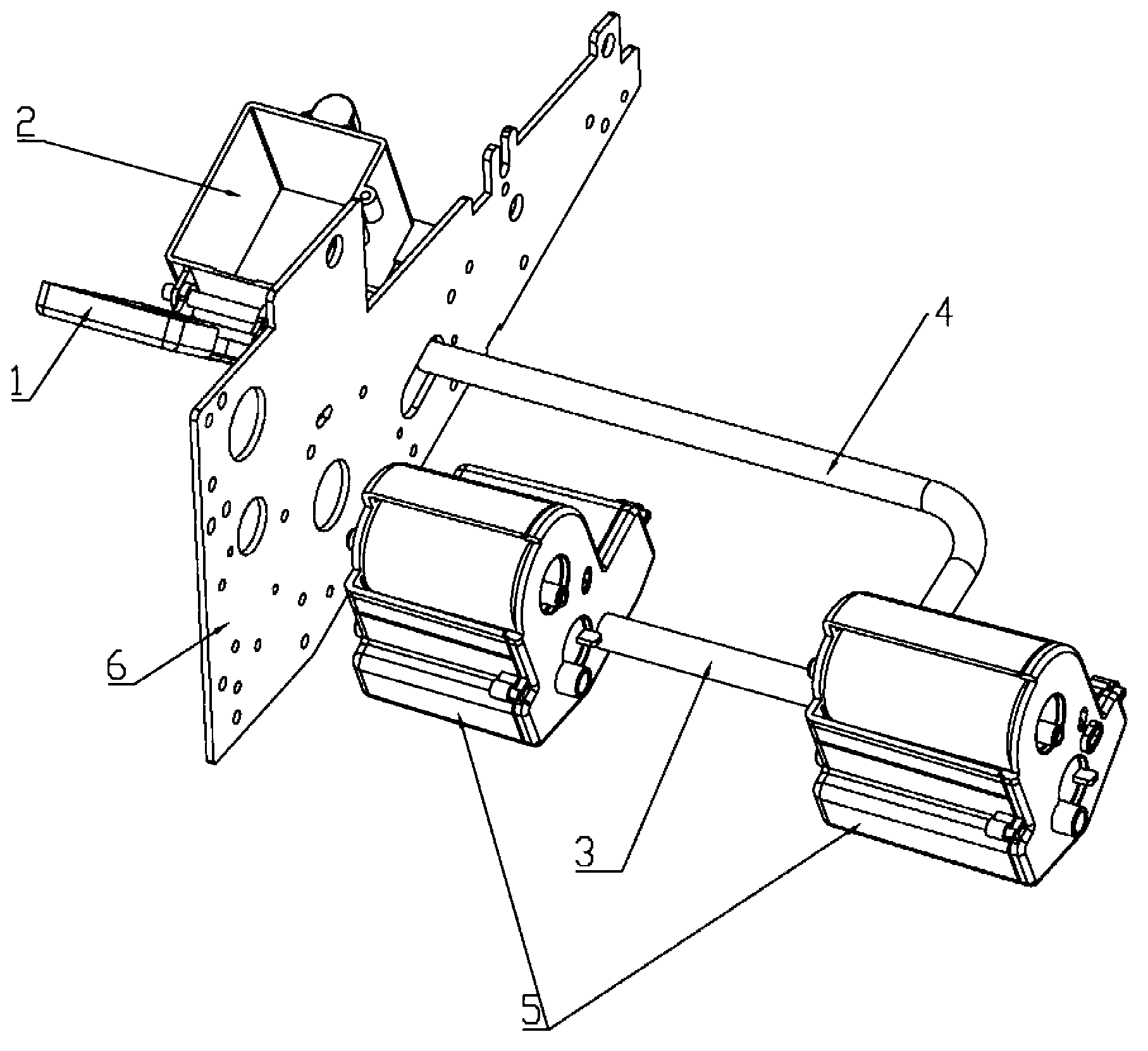

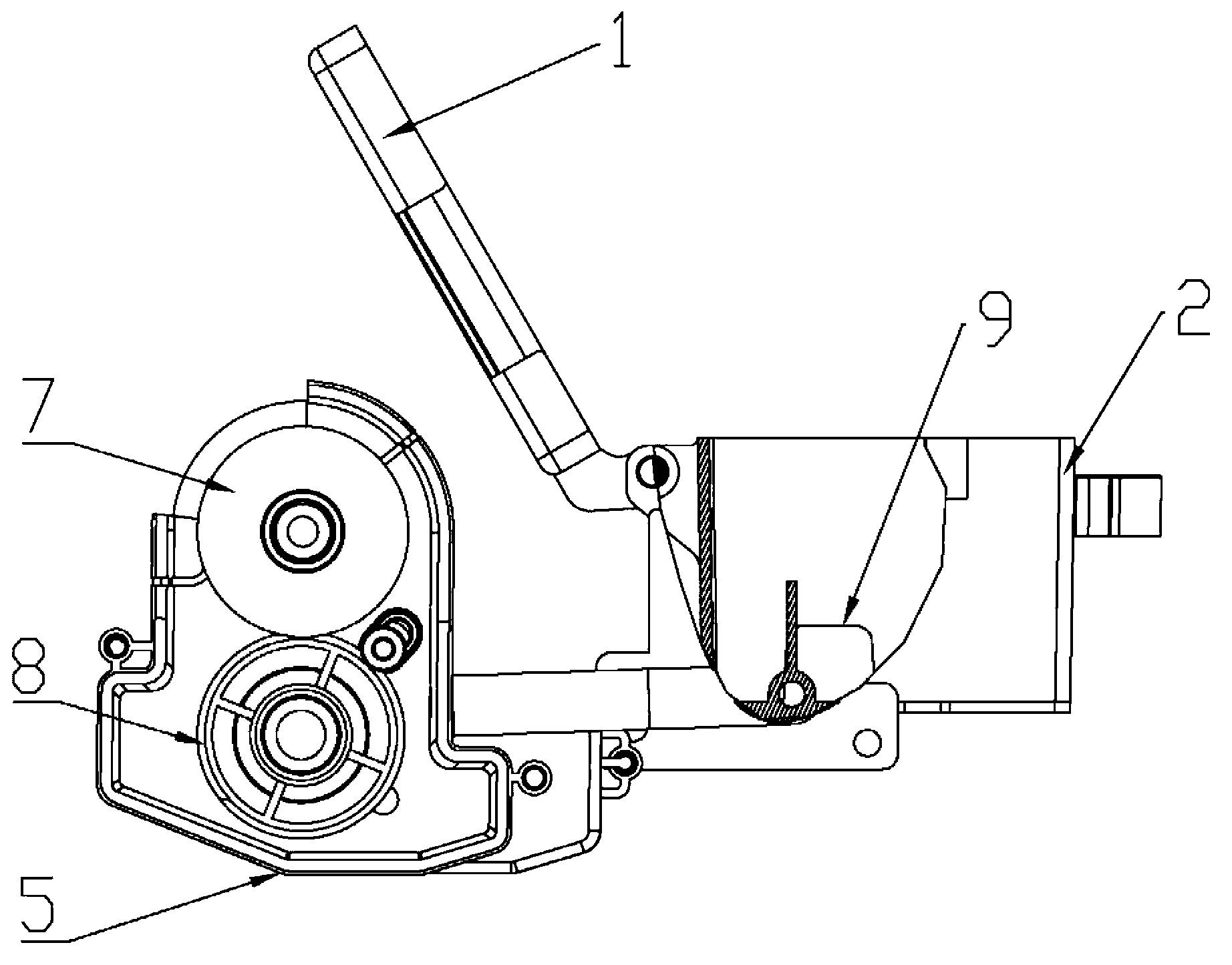

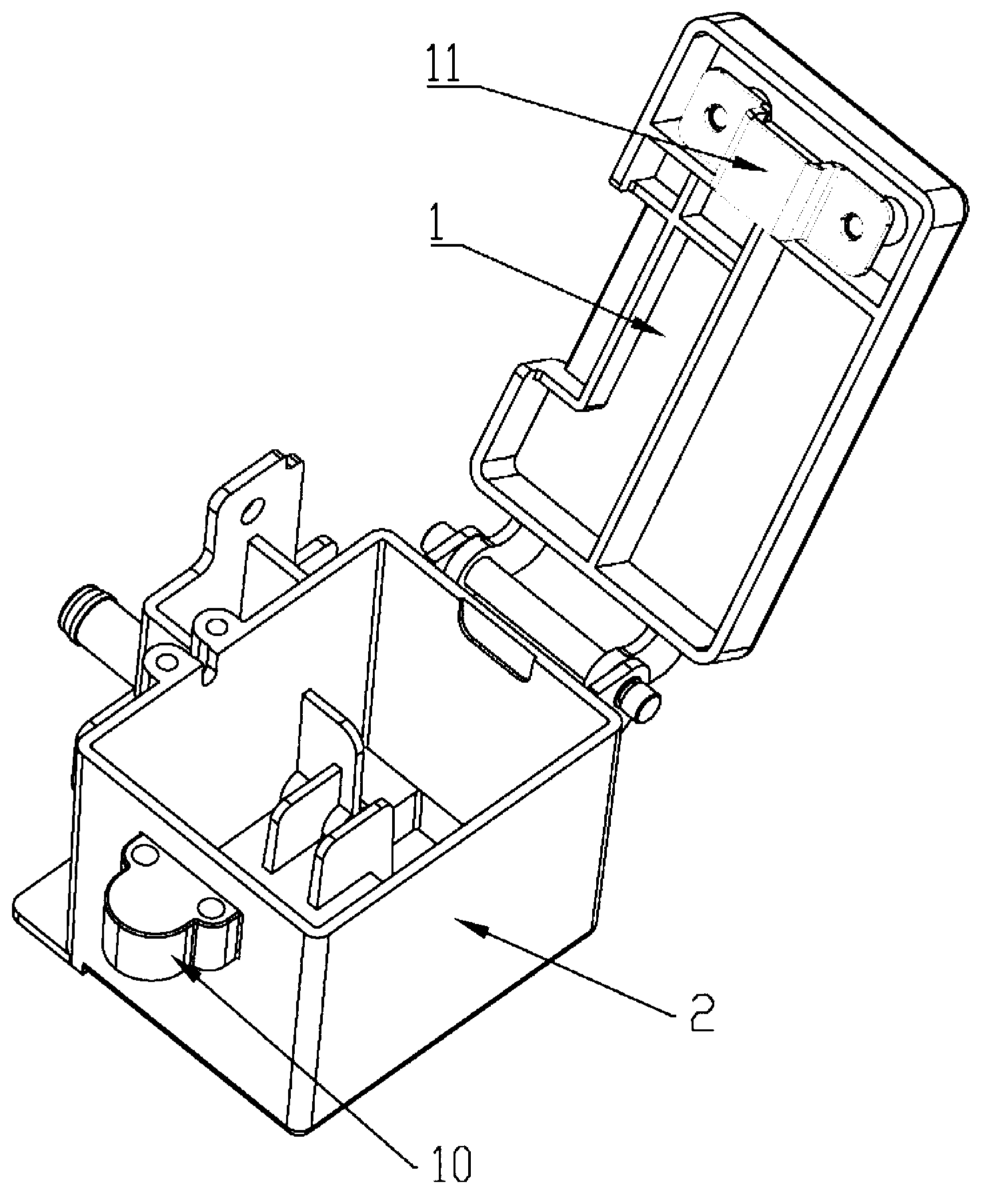

[0027] Such as Figure 1-4 , The convenient oil refilling device of the stamping machine includes a refueling box and the oil pipe of the Unicom refueling box and the refilling ink box; the refueling box is set on the side panel of the bank self-stamping terminal, and the refueling box is provided with a flip-top cover.

[0028] A filling indication is provided in the fuel box, the top surface of the step is a datum surface for ink filling, and the oil filling tank is provided with an oil tanker and a tanker. The datum surface for ink filling is lower than the lowest point of the oil tanker.

[0029] There are two ink cartridges, two oil pipes (namely, the first leather tube and the second leather pipe), and the two oil pipes are respectively connected to the two ink cartridges. (Or as figure 1 As shown, the first oil pipe is connected to the fuel tank and the ink cartridge, and the second oil pipe is connected to the two ink cartridges)

[0030] The front end of the upper cover is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com