Automatic machining process and machining device for pipe packaging

A technology of automatic processing and processing equipment, applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the working mode that cannot be completely thrown away from multi-person auxiliary operations, it is difficult to mechanize automatic casing, and the operation purpose cannot be achieved and other problems, to achieve the effect of solving the loss of raw materials and error-prone, reducing the waste of human resources, and rigorous processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

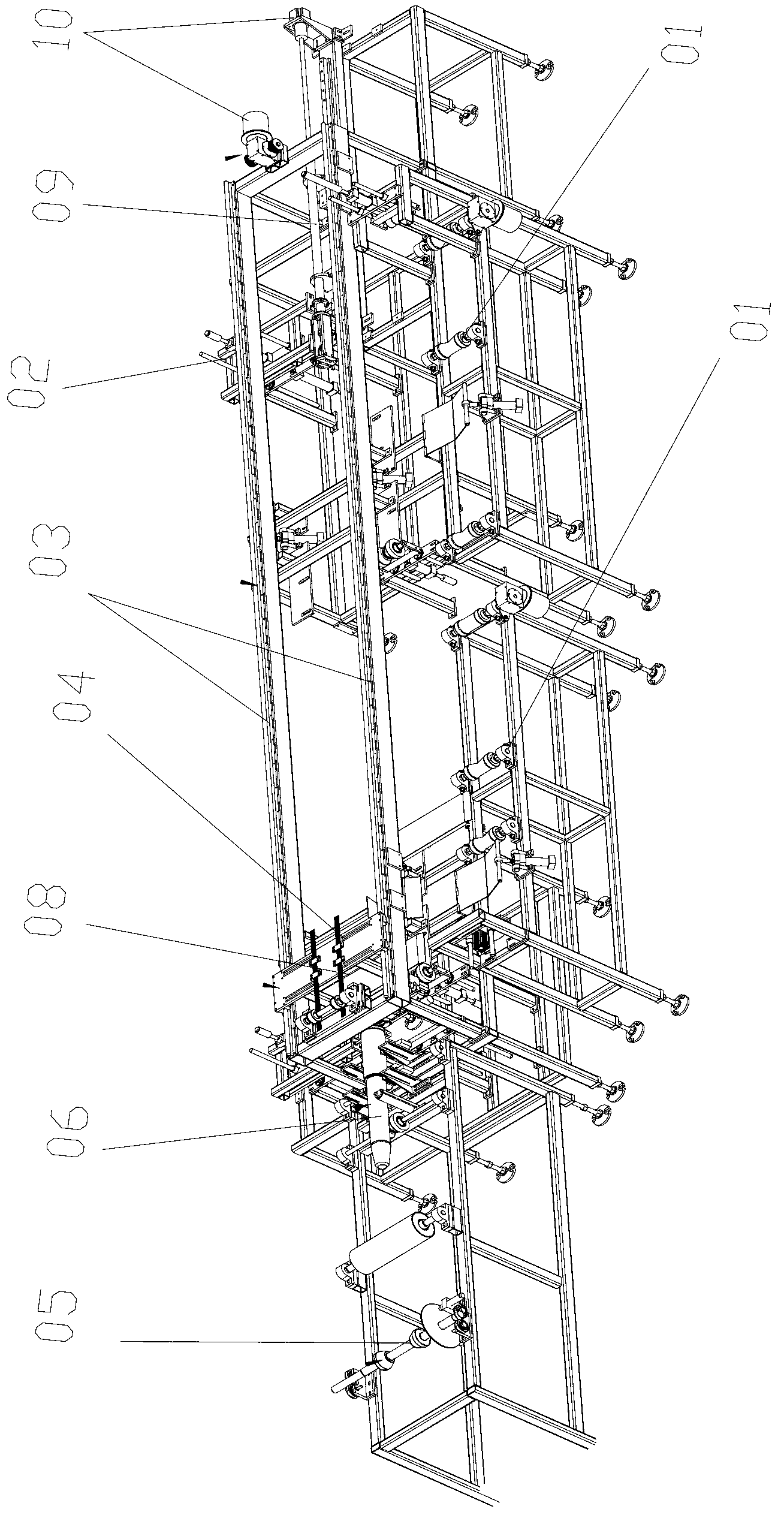

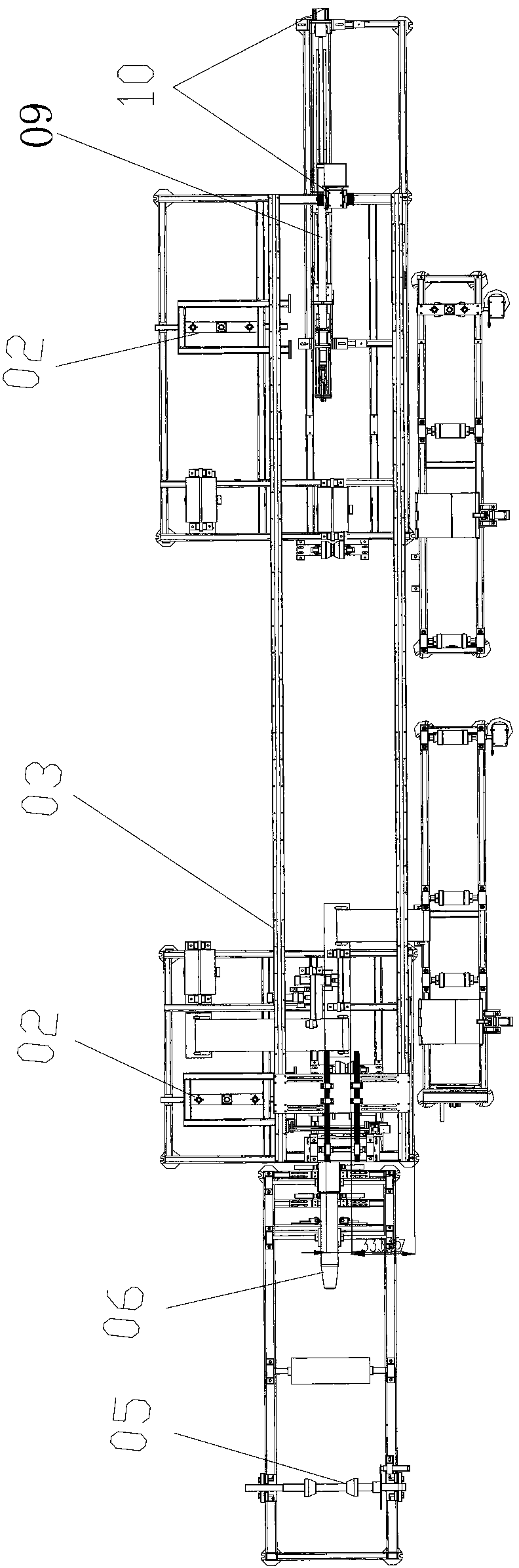

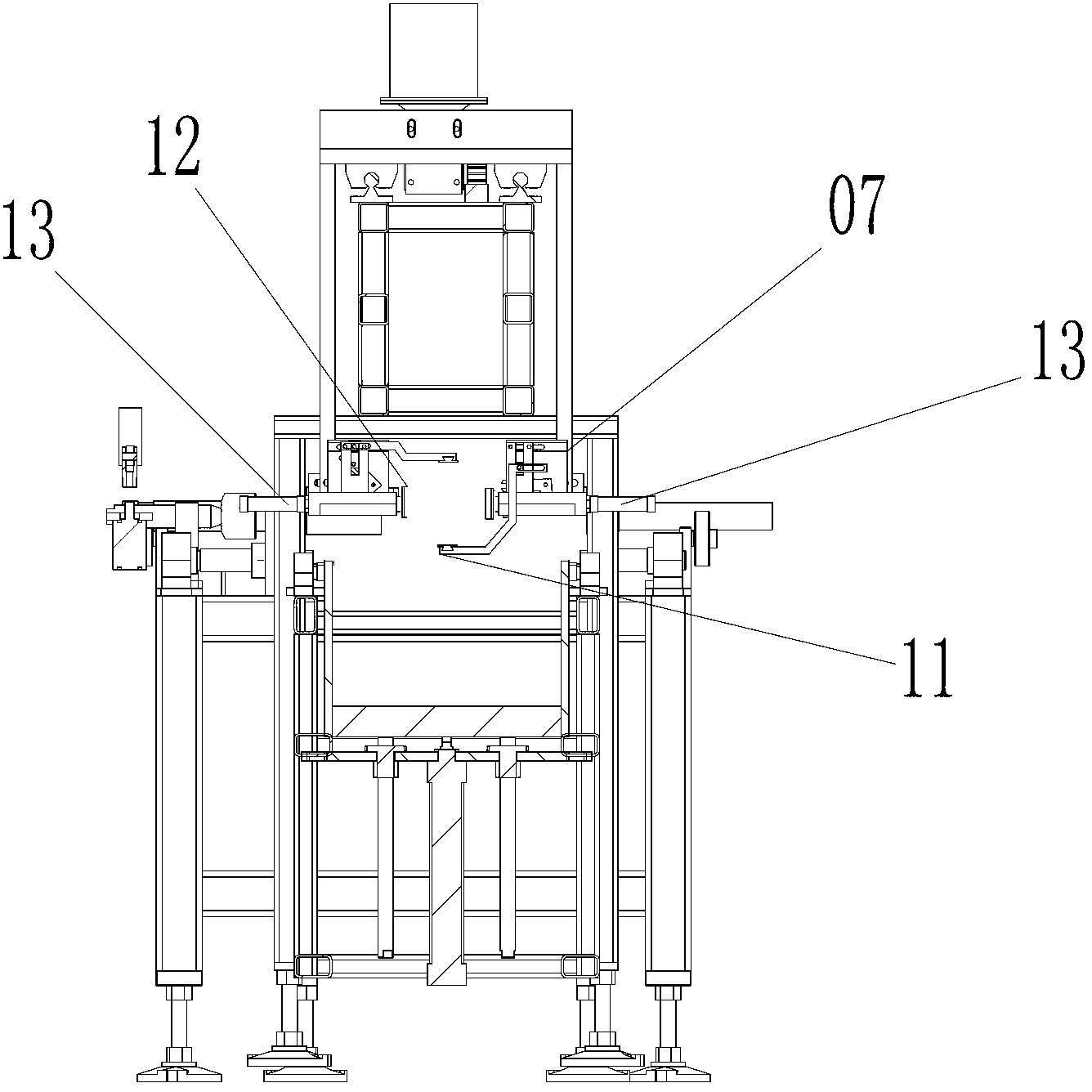

[0031] like figure 1 and image 3 As shown, the automatic processing technology of pipe packaging in the present embodiment comprises the following steps:

[0032] (1) Set the pipes to be packaged and the adhesive tape used for packaging, and set up a processing device. Set the turning mechanism 01 outside the main body of the frame of the device, set the sealing device 02 at both ends of the inside, and set the transmission track 03 in the middle packaging area. And on the transmission track 03, an integratedly designed casing clamping mechanism 04 and a casing pre-supporting mechanism 07 are installed, and a tape fixing mechanism 05 and a guide tube 06 are arranged on the left side. A cutting device 08 is also provided, and the right side is provided with a propulsion device 09 and a transmission mechanism 10; the clamping mechanism 04 is provided with a clamp 12 for tape clamping and a traction device for pulling the tape to move, and the propulsion device 09 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com