Rubber environment-friendly glue-free floor and floor block thereof

An environmentally friendly, floor board technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of poor anti-slip effect, scratch resistance and wear resistance, and difficult to clean, and achieve better anti-slip effect and aesthetic effect. Best easy to clean, anti-slip effect and enhanced aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

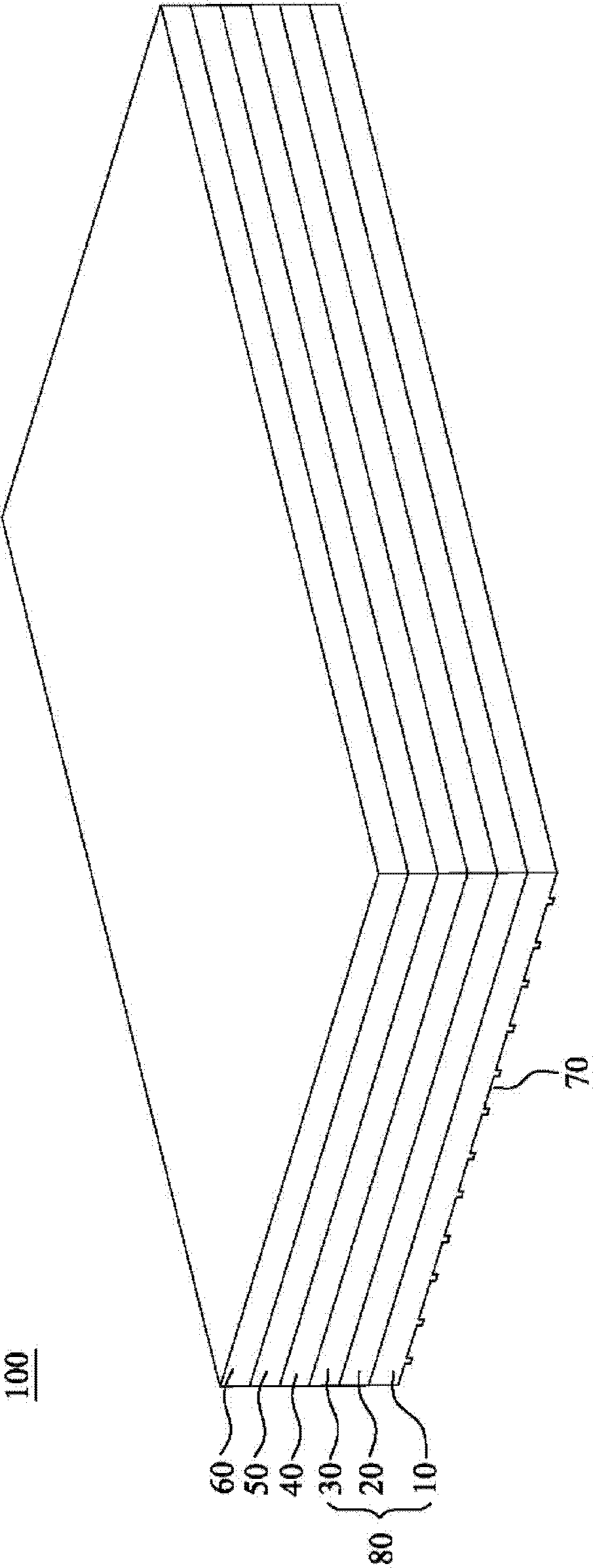

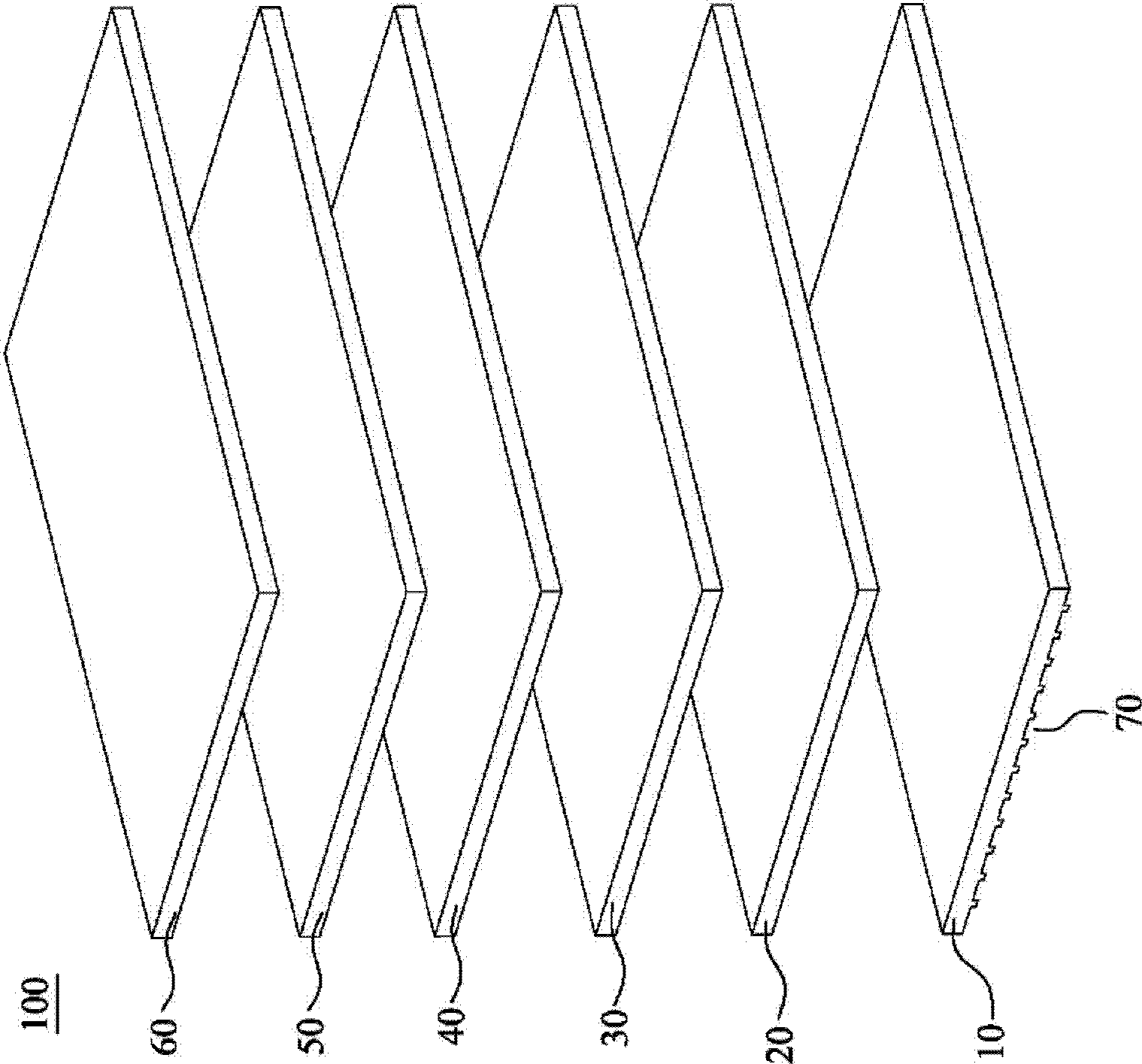

[0029] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the bottom material layer 10 of the mixed body, the anti-alteration material layer 20, the middle layer of the mixed body, which are sequentially stacked and hot-pressed from bottom to top. Material layer 30, printing film 40, transparent wear-resistant layer 50 and PU wear-resistant layer 60.

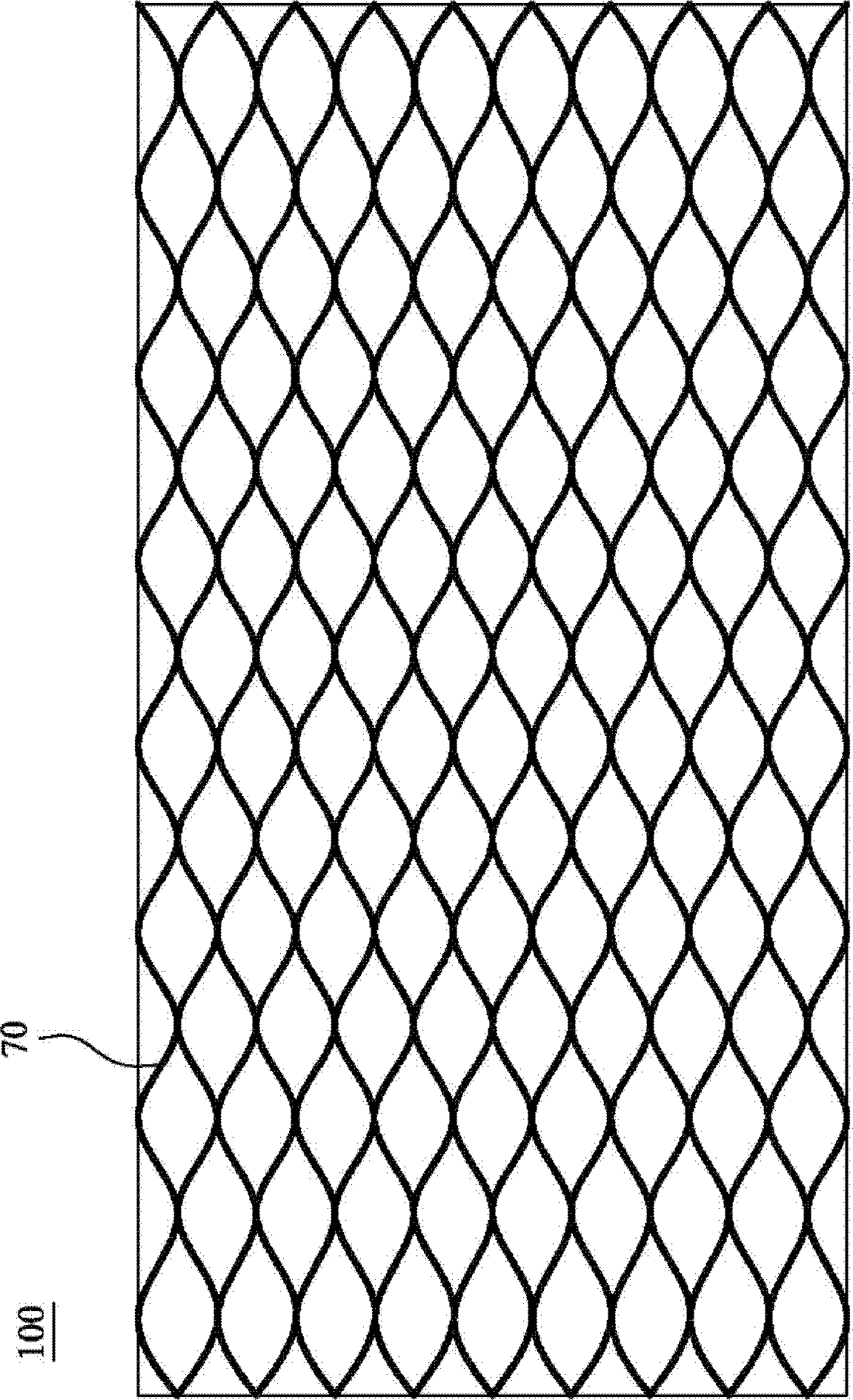

[0030] Wherein, the bottom surface of the mixed base material layer 10 in contact with the ground is hot-pressed to form a texture 70, the texture 70 includes a plurality of wavy convex ribs 71 arranged side by side, and two adjacent wavy convex ribs 71 are symmetrically connected to each other And enclosing the adsorption disc 72 of a plurality of closed diamond-shaped concave cavity formulas, the test proves that the adsorption disc 72 formed by the wavy convex rib 71 of this shape has stronger adsorption force, better anti-skid effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com