Wellhead Backpressure Control System and Wellhead Backpressure Control Method for Managed Pressure Drilling

A technology of managed pressure drilling and control system, which is applied to the automatic control system of drilling, drilling equipment, wellbore/well components, etc. The problem of high cost of the pressure pump can achieve the effect of removing high failure factors, simplifying pressure control equipment, and reducing the number of valves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

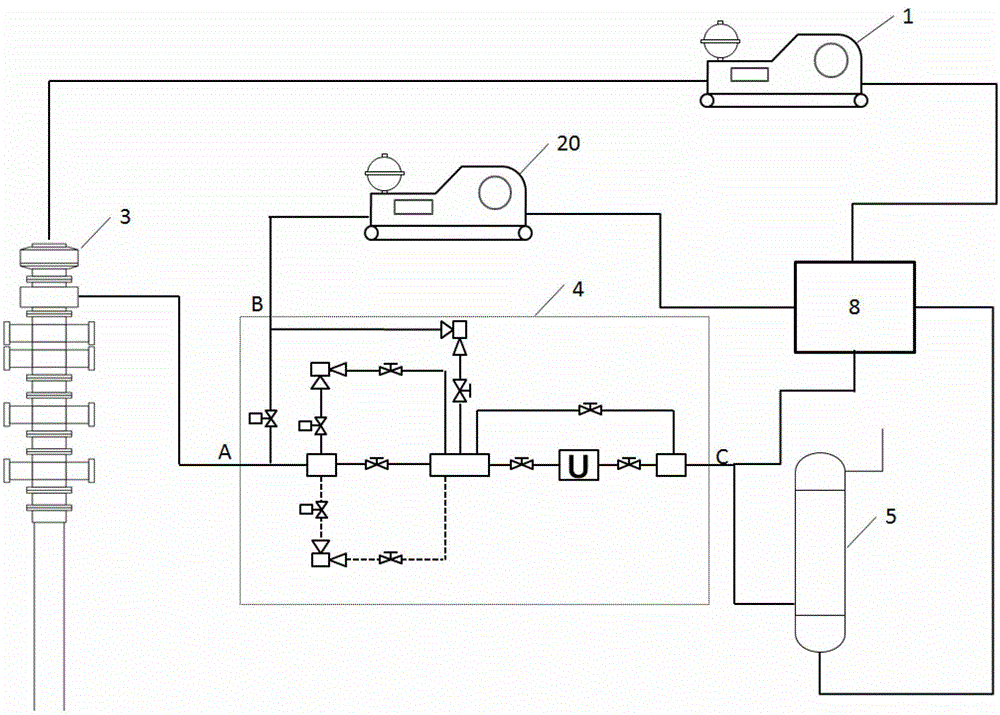

[0037] Such as Figure 4 As shown, the wellhead back pressure control system of managed pressure drilling according to the embodiment of the present invention includes:

[0038] A mud pump 1, the mud pump has an inlet and an outlet, the inlet is connected to the mud pool 8, and the outlet is connected to the riser;

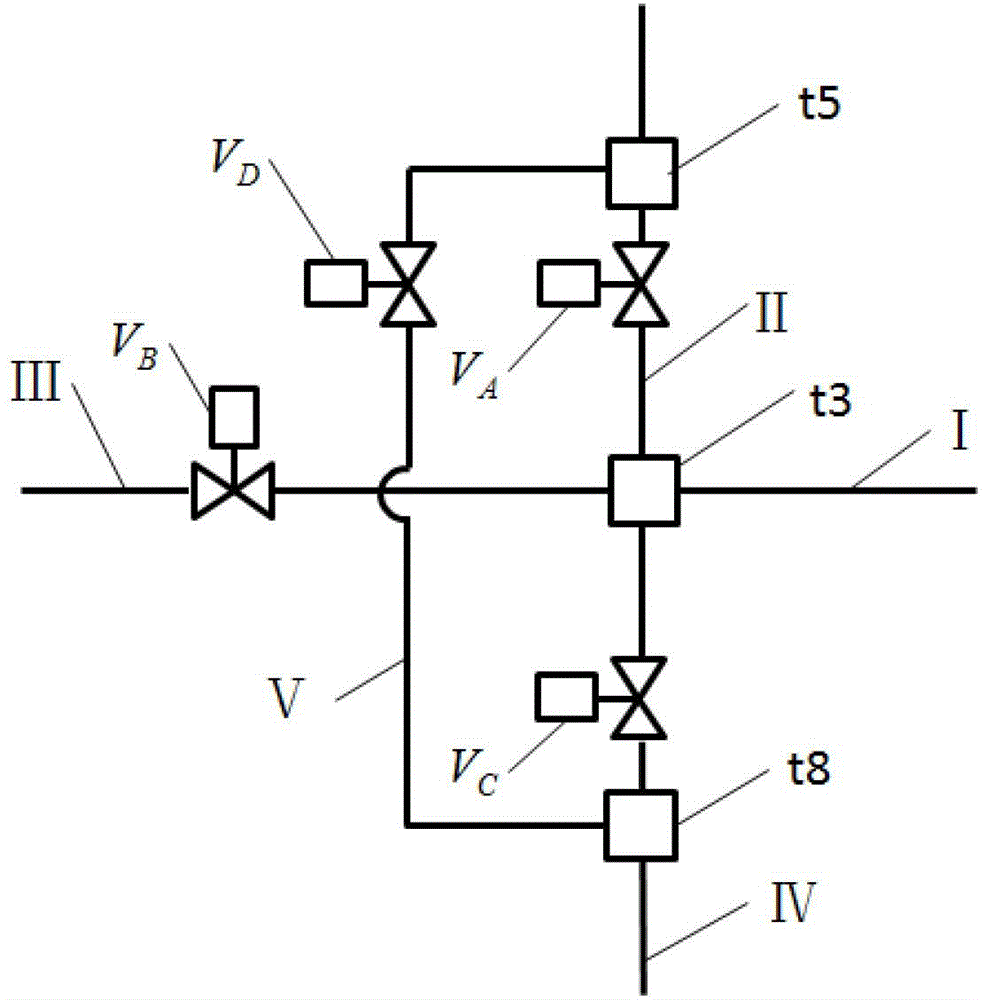

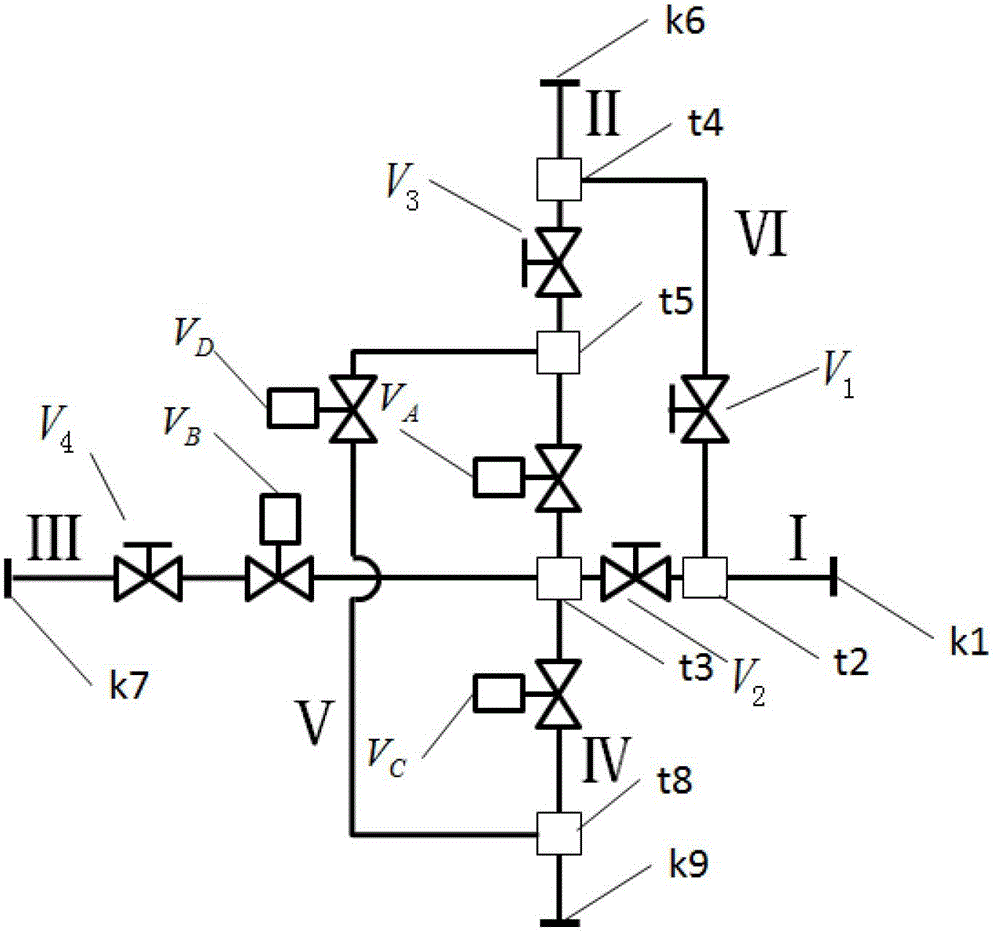

[0039] Pressure control automatic choke manifold (also called automatic choke manifold or control drilling choke manifold) 4, the pressure control automatic choke manifold has port A and port C, the pressure control automatic choke manifold The port A of the rotary blowout preventer 3 is connected to the main bypass port of the rotary blowout preventer 3, and the pressure control automatic throttle manifold also has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com