A tunnel lighting and ventilation integrated device and its manufacturing method

A technology of tunnels and ventilation towers, applied in mine/tunnel ventilation, tunnels, mining equipment, etc., can solve problems such as consumption and large power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A highway tunnel has a length of 2km and a width of 10m. The lighting-ventilation integrated device of the present invention is implemented.

[0032] (1) The structure of the lighting-ventilation integrated device

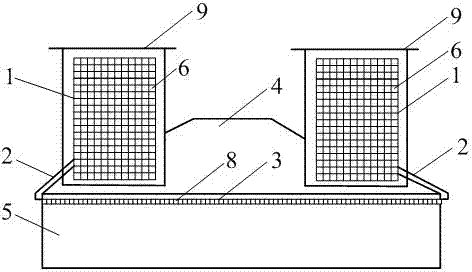

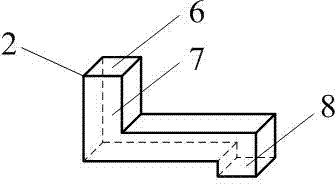

[0033] The lighting-ventilating integrated device of the present invention is composed of a lighting-ventilating tower 1 outside the tunnel 4, a lighting-ventilating wall 3 inside the tunnel 5, and a lighting-ventilating pipe 2 connecting the "tower" and the "wall".

[0034] Lighting-ventilation tower 1 It is in the shape of a prism, and the surroundings and the top of the tower are arranged by the outlets 6 of the lighting-ventilation pipes 2; the top of the tower is provided with a transparent glass rainproof ceiling 9. The height of a single lighting-ventilation tower is 20m, the cross section is square, and the side length is 10m. 25 lighting-ventilation towers are installed, and 800 outlets of lighting-ventilation pipes are installed around each l...

Embodiment 2

[0045] A municipal road tunnel has a length of 1km and a width of 20m. The lighting-ventilation integrated device of the present invention is implemented.

[0046] (1) The structure of the lighting-ventilation integrated device

[0047] The lighting-ventilating integrated device of the present invention is composed of a lighting-ventilating tower 1 outside the tunnel 4, a lighting-ventilating wall 3 inside the tunnel 5, and a lighting-ventilating pipe 2 connecting the "tower" and the "wall".

[0048] Lighting-ventilation tower 1 It is in the shape of a prism, and the surroundings and the top of the tower are arranged by the outlets 6 of the lighting-ventilation pipes 2; the top of the tower is provided with a transparent glass rainproof ceiling 9. The height of a single lighting-ventilation tower is 50m, the cross section is square, and the side length is 20m. A lighting-ventilation tower is set up, and a total of 100,000 lighting-ventilation pipe outlets are set around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com