Power supply control switch

A power control and switch technology, applied in electric switches, flip/rocker switches, circuits, etc., can solve the problems of large material loss, product performance cannot be guaranteed, LED display lights cannot be placed in active areas, etc., to reduce difficulty, Increase the transmission effect and facilitate the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

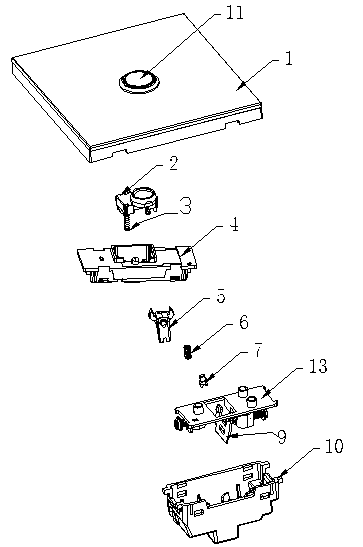

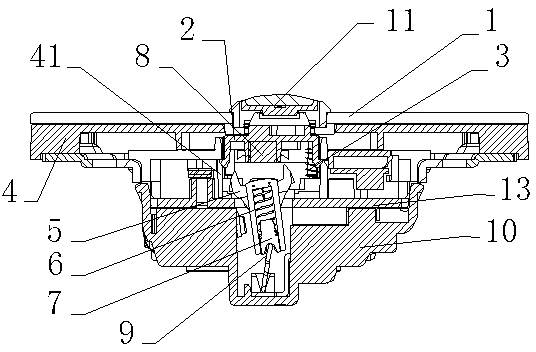

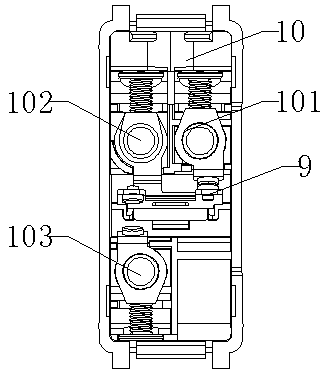

[0055] like figure 1 , 2 As shown, a power control switch includes a panel 1, a switch system, and a rear seat 10. The above-mentioned panel 1 is provided with a button 11 for transmitting external pressure, and the above-mentioned switch system is installed on the rear seat 10 and the panel. 1, such as image 3 As shown, the bottom of the rear seat 10 described above is installed with conductive side posts I101, conductive side posts II 102, and conductive brackets 103; the switch system described above is a self-resetting reciprocating switch structure, which includes the following structural components:

[0056] like Figure 4 As shown, the pressure block assembly 2 is used as the first component to withstand the external pressing force, and the pressure block assembly 2 maintains a degree of freedom of up and down movement; the space lower end limit system of the pressure block assembly 2 is arranged on the transition assembly 4 The compression spring 3 is against the p...

Embodiment 2

[0068] like Figure 10-13 As shown, on the basis of Embodiment 1, an indicator system is also included, and the indicator system includes an LED light-emitting lamp 122 installed on the transition assembly 4 and a transparent astigmatism button 121 installed on the pressing block assembly 2; The transparent astigmatism button 121 is provided with a spherical arc surface 1210 for diffusing the light of the LED light-emitting lamp 122 .

[0069] Since Embodiment 2 is a further improvement of Embodiment 1, the technical problem to be solved in Embodiment 2 on the basis of Embodiment 1 is: the indicator light system can identify the button position for the operator in a dark environment. Since the above-mentioned transparent astigmatism button is provided with a spherical arc surface that makes the LED light emitting light diverge, in this way, a beautiful halo can be generated and the grade of the product can be increased.

Embodiment 3

[0071] like Figure 14-15As shown, on the basis of Embodiment 2, the conductive side post I101, the conductive side post II 102 and the conductive bracket 103 installed at the bottom of the rear seat 10 are provided with a cover plate 13, and the cover plate 13 is provided with a cover plate 13. There are two hollow cylinders 131, one of the hollow cylinders 131 is directly below the conductive support 103, and the other hollow cylinder 131 is directly below the conductive side post I101; the two hollow cylinders 131 are respectively provided with a Conductive spring 14 that powers the indicator system.

[0072] In the actual use process, after installing the conductive side post I101, the conductive side post II 102, and the conductive support 103, then install the cover plate 13, and further install the conductive spring 14. The conductive spring 14 supplies power to the indicator system.

[0073] The technical problem to be solved in Embodiment 3 is: the problem of supplyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com