Full-automatic slot incoming machine for storage battery plate pack

A pole group and battery technology, applied in the field of automatic battery combination pole group slotting machine, can solve the problems of lead dust, low production efficiency, large human factors, etc., to reduce labor costs, improve efficiency, Avoid inefficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following implementation example.

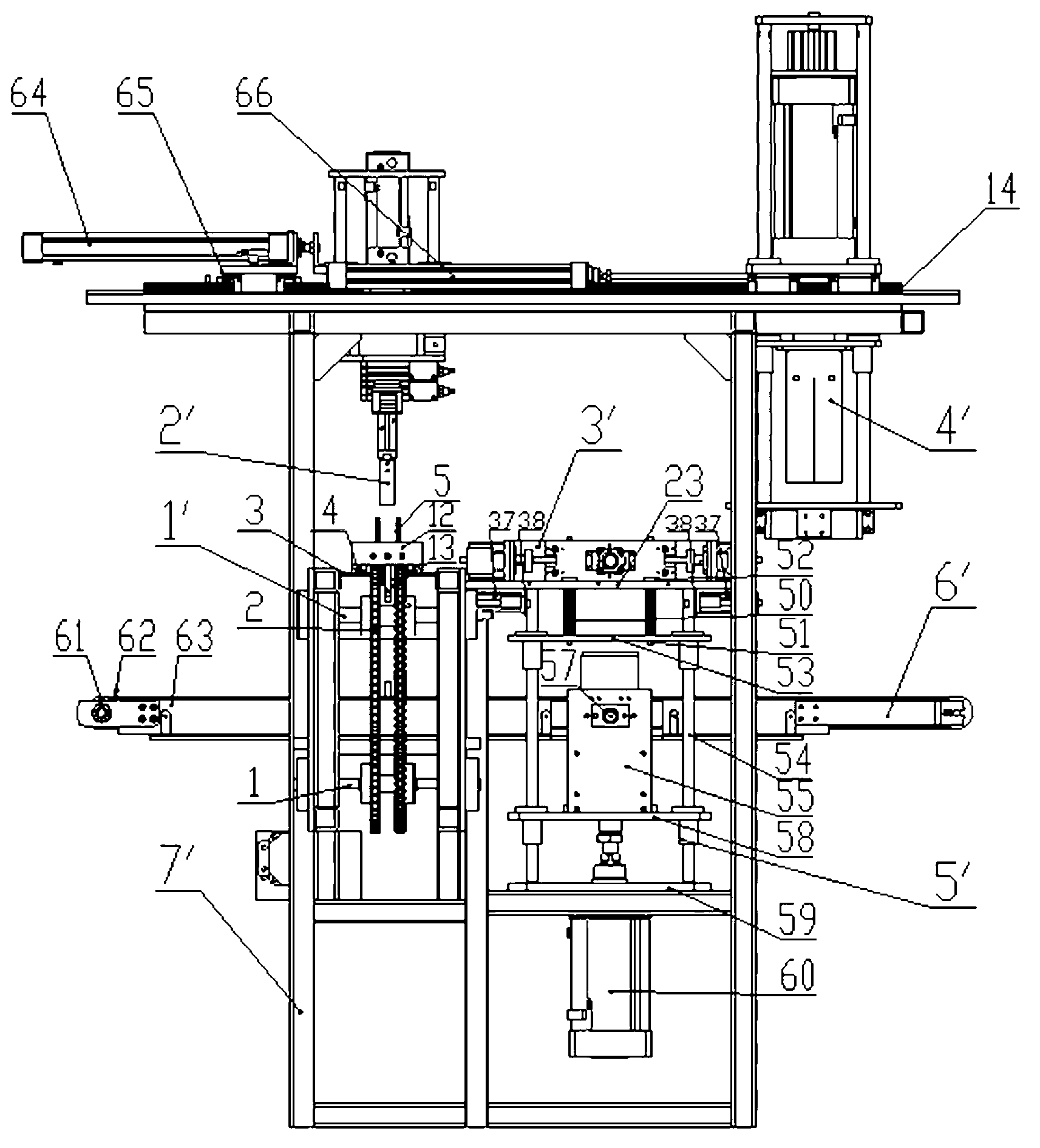

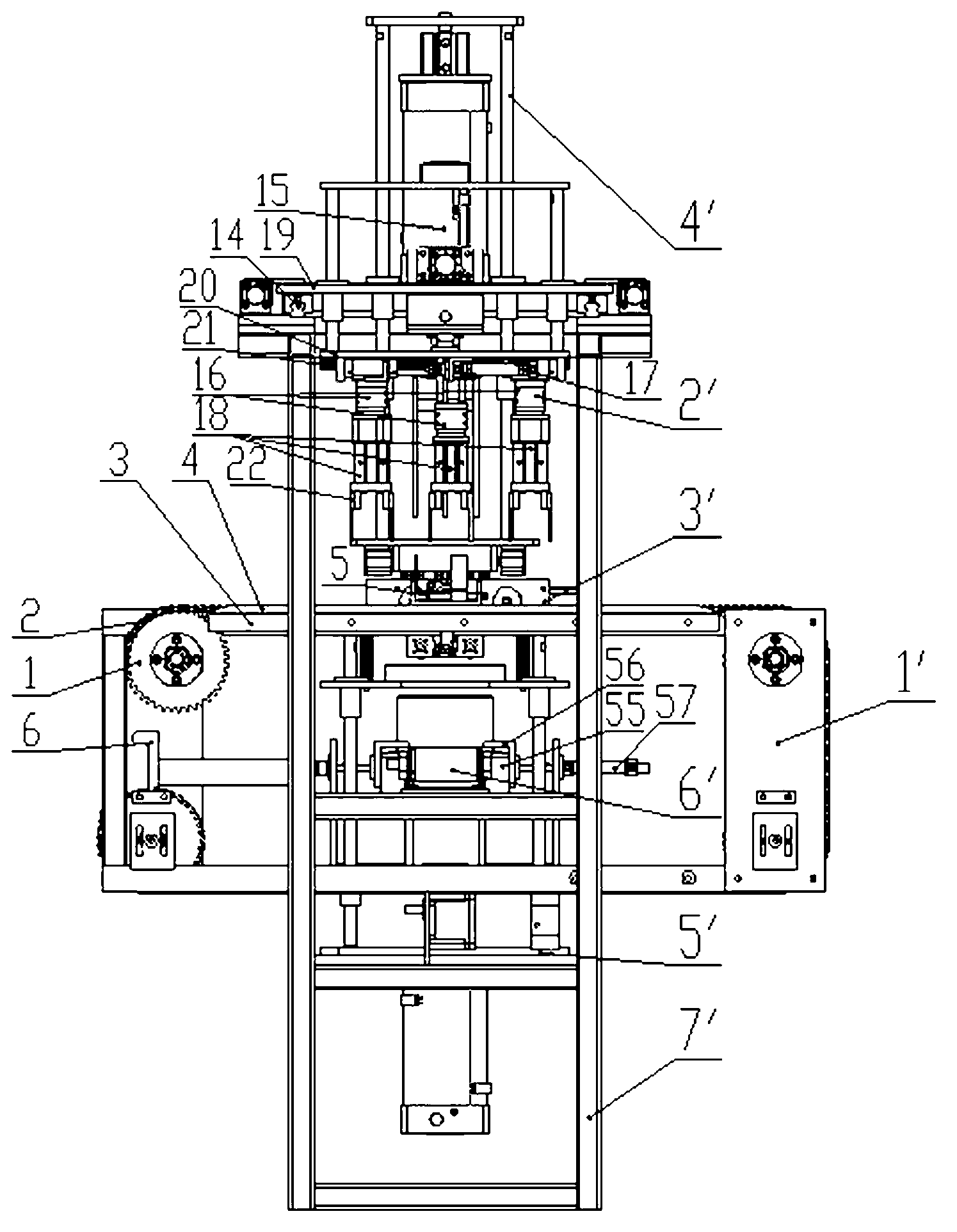

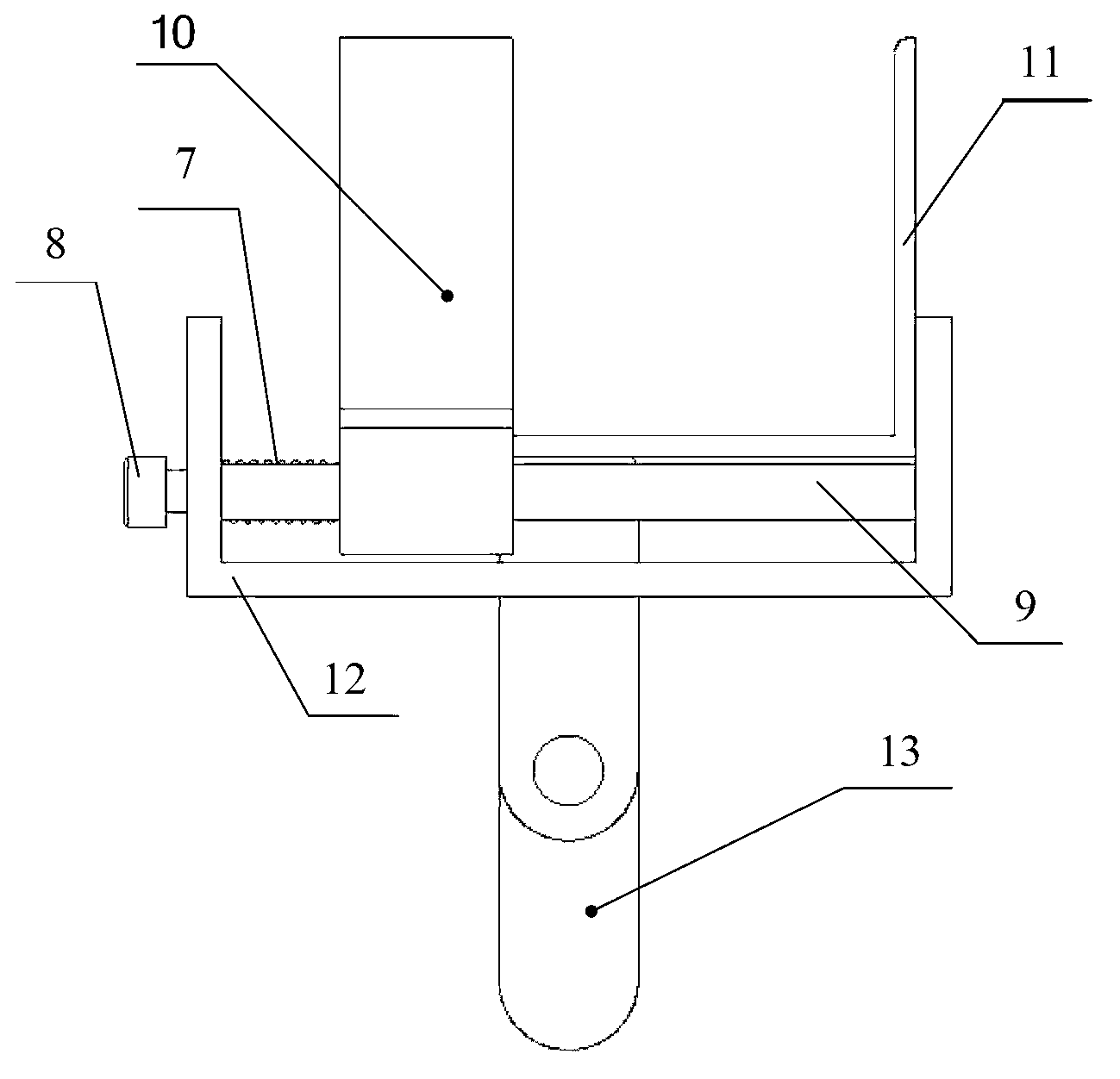

[0033] Such as figure 1 and figure 2 As shown, this embodiment includes: a material receiving and erecting mechanism 1' for realizing material receiving and erecting pole groups, a manipulator mechanism 2' for simultaneously grasping and placing several sets of pole groups, and a shaping mechanism for combining pole groups 3', the assembly mechanism for realizing the tab shaping of the combined pole group and loading into the box groove 4', the battery box jacking mechanism 5', the battery box output mechanism 6', and the frame for carrying the above mechanisms 7' . Wherein, the erecting mechanism 1' for connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com