Liquid curing agent for epoxy resin

A liquid curing agent, curing agent technology, applied in the field of epoxy resin-composition, can solve problems such as preventing the complete curing of composite materials

Active Publication Date: 2016-03-16

ALZCHEM TROSTBERG

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This prevents complete curing of the entire composite

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0103] I. Mixtures and curing agents according to the invention

[0104] 1) Preparation according to the mixture and curing agent of the present invention

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Description

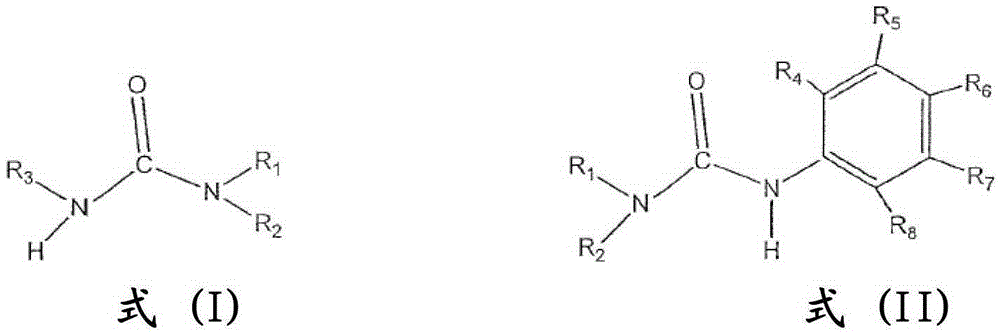

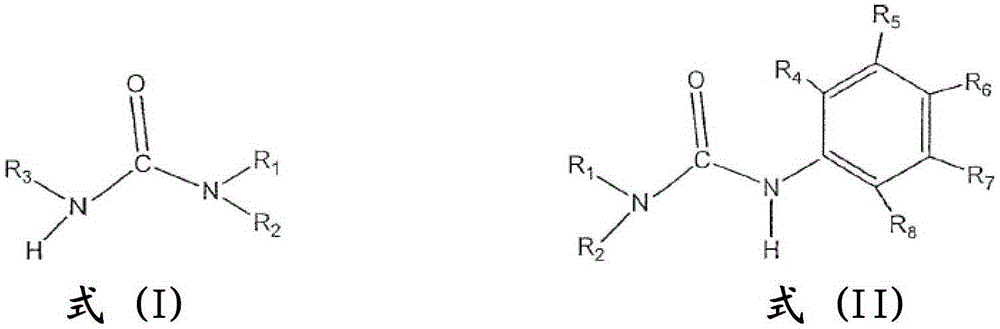

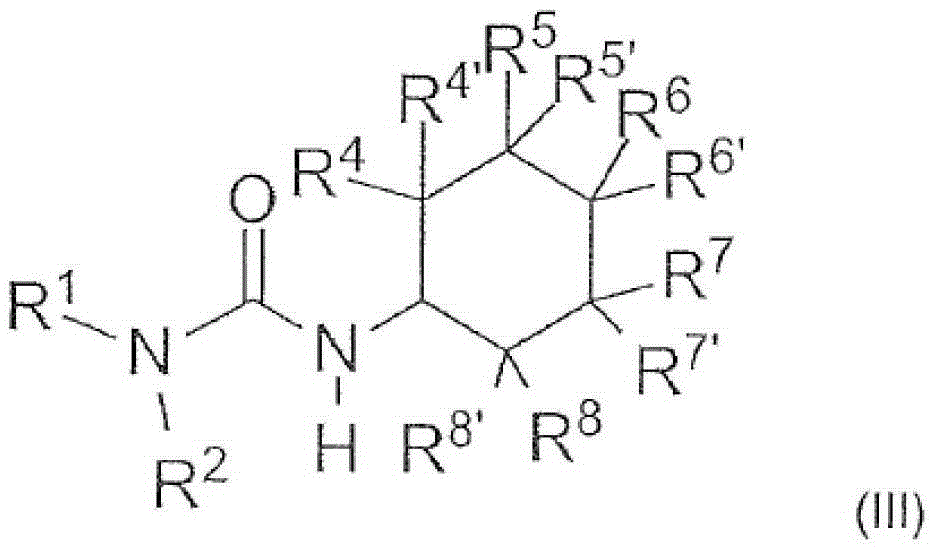

technical field [0001] The invention relates to novel mixtures comprising cyanamide and at least one urea derivative, liquid curing agents for curing epoxy resins, and epoxy resin compositions comprising liquid curing agents for the production of fiber composites. Background technique [0002] Thermosetting epoxy resins are widely used due to their good chemical resistance, very good thermal and dynamic-mechanical properties and high electrical insulating capacity. Furthermore, epoxy resins show good adhesion to many substrates and are therefore most suitable for use in fiber composites (composites). For use in fiber composites, both good wetting of the fibers, ie, low viscosity of the resin formulation selected for the production of the composite, and high mechanical properties after complete curing are desired. [0003] Molded parts are produced from fiber composite materials using various methods, such as pre-impregnation methods, various infusion methods or injection me...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G59/44C08G59/46

CPCC08G59/4021C08L63/00C08G59/46C08G59/44C08K5/21C08L75/04C08G18/06

Inventor S·施特罗贝尔M·艾伯纳H-P·克里默M·胡博

Owner ALZCHEM TROSTBERG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com