IC device having electromigration resistant feed line structures

A device and active circuit technology, applied in the field of IC devices with anti-electromigration feeder structure, can solve problems such as low efficiency and increased processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

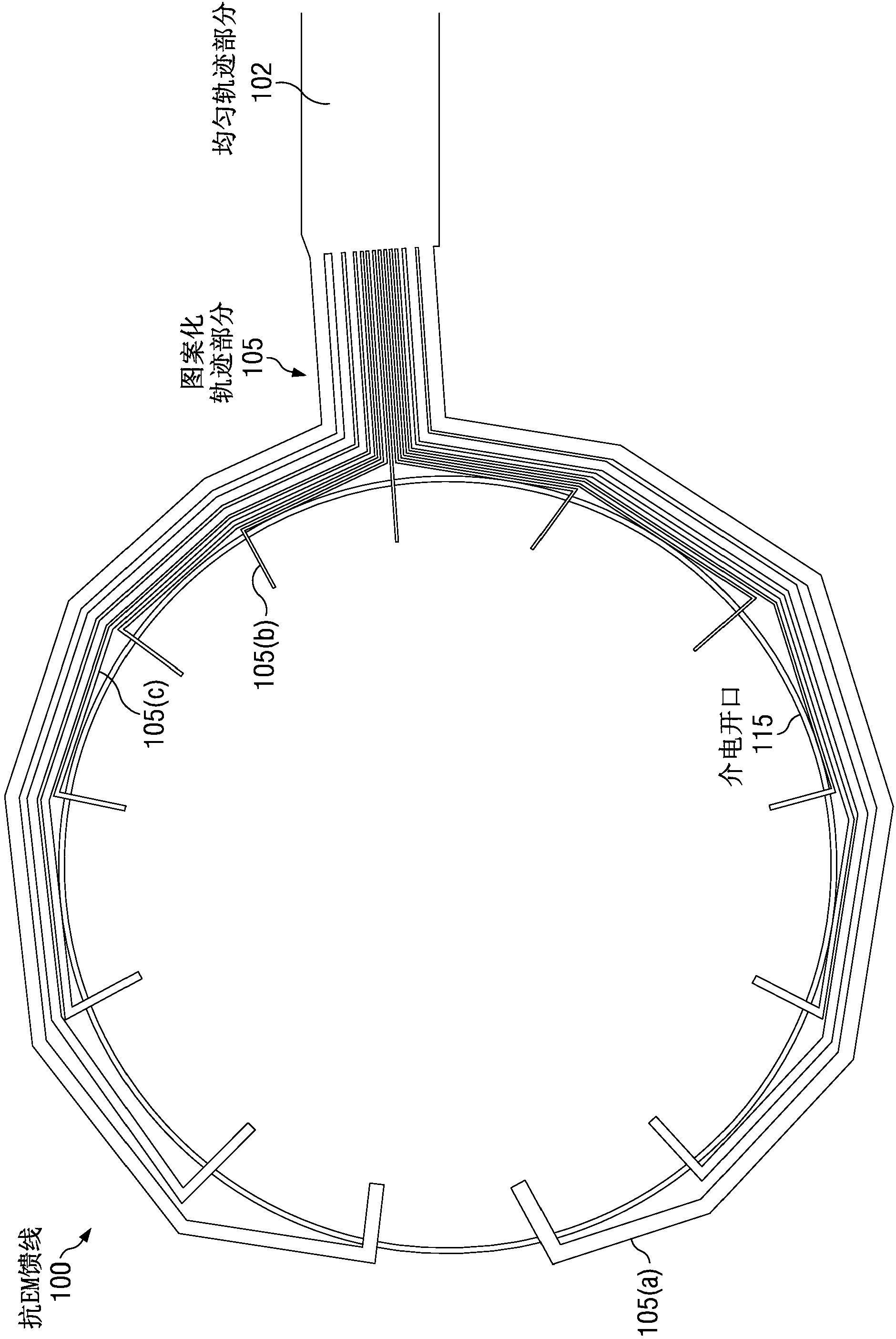

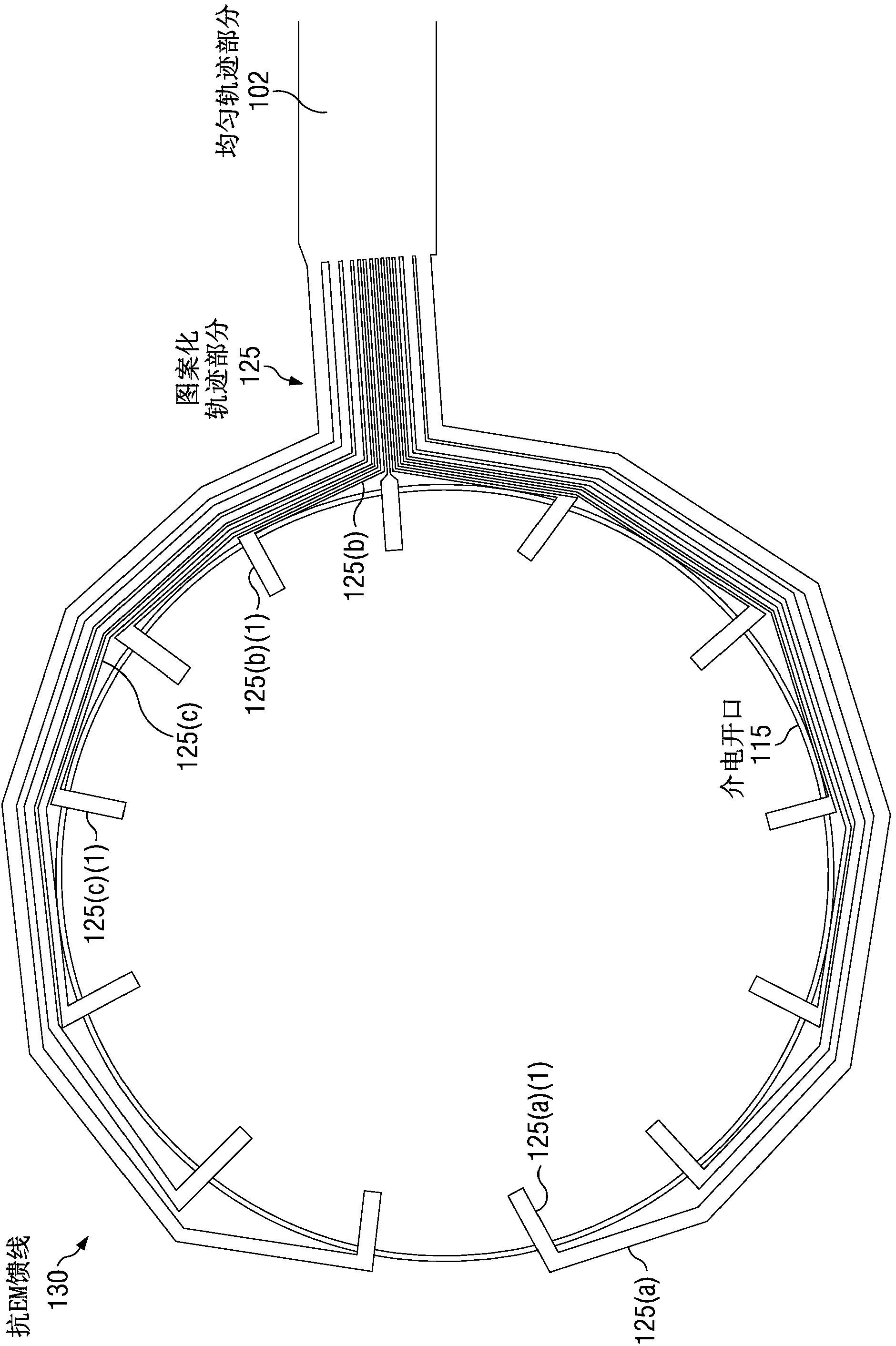

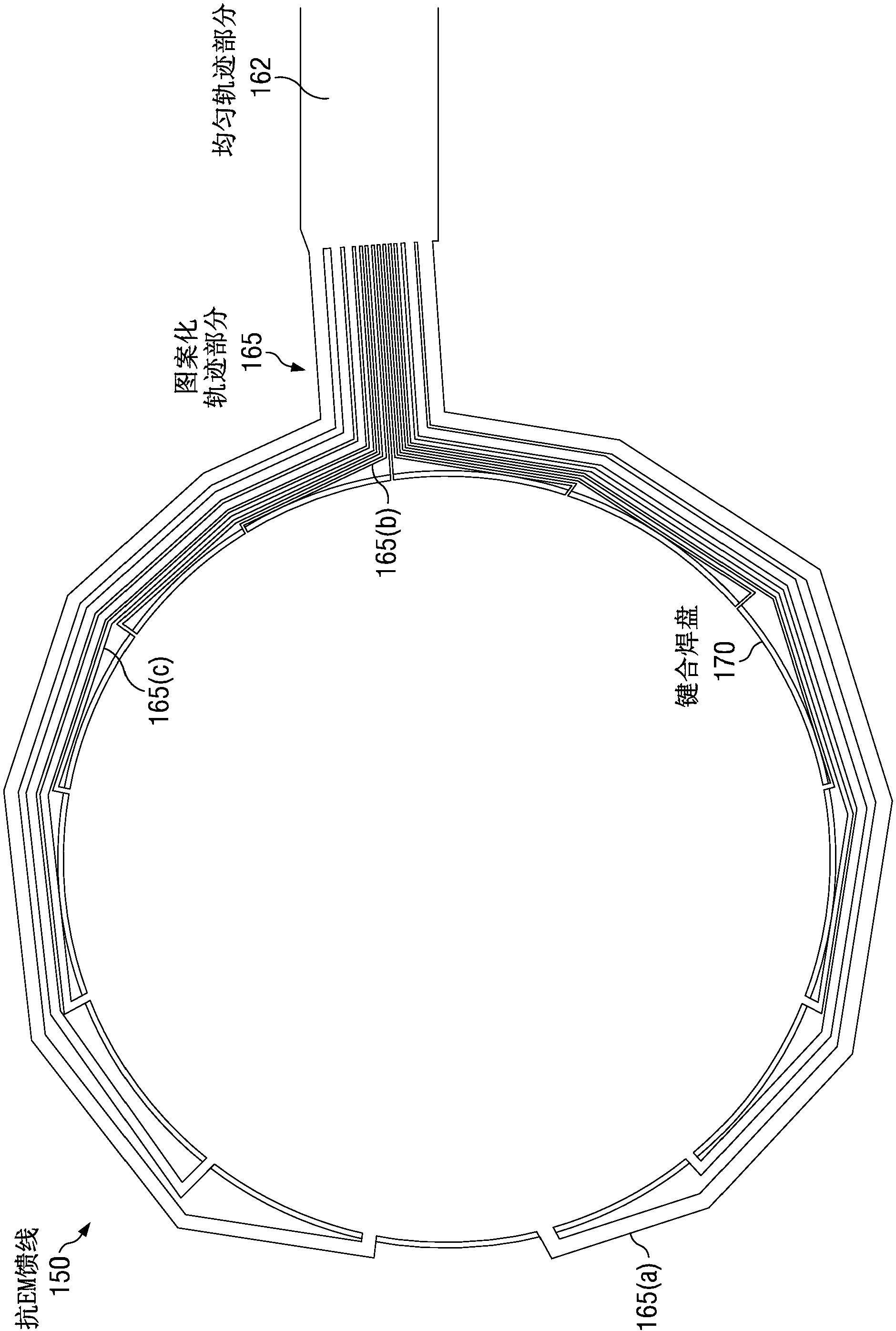

[0022] Figure 1A An example EM resistant feedline structure 100 is shown providing an edge feed with at least three sub-traces providing substantially equal sub-trace currents distributed substantially equally around the circumference of the dielectric opening 115 under the bond according to an example embodiment. although Figure 1A One larger dielectric opening 115 is shown in , but disclosed embodiments may instead include smaller dielectric openings or both larger and smaller dielectric openings under later formed bonds. . Bonds are generally described herein as solder bumps. However, the bond may also contain through-substrate vias (TSVs), pillars (e.g., copper pillars), studs (e.g., gold studs), or organic bonds with multiple metal particles. material.

[0023] The EM resistant feedline structure 100 comprises a uniform (eg, conventional) trace portion 102 coupled to a patterned trace portion 105 comprising at least three electrically parallel and distributed traces 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com