Crystal boat automatic purge device

An automatic and crystal boat technology, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve the problems of low product yield, high production cost, transporting quartz parts, etc. efficiency, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following describes the implementation of the present invention in detail with the drawings and embodiments, so as to fully understand and implement the implementation process of how the present invention uses technical means to solve technical problems and achieve technical effects.

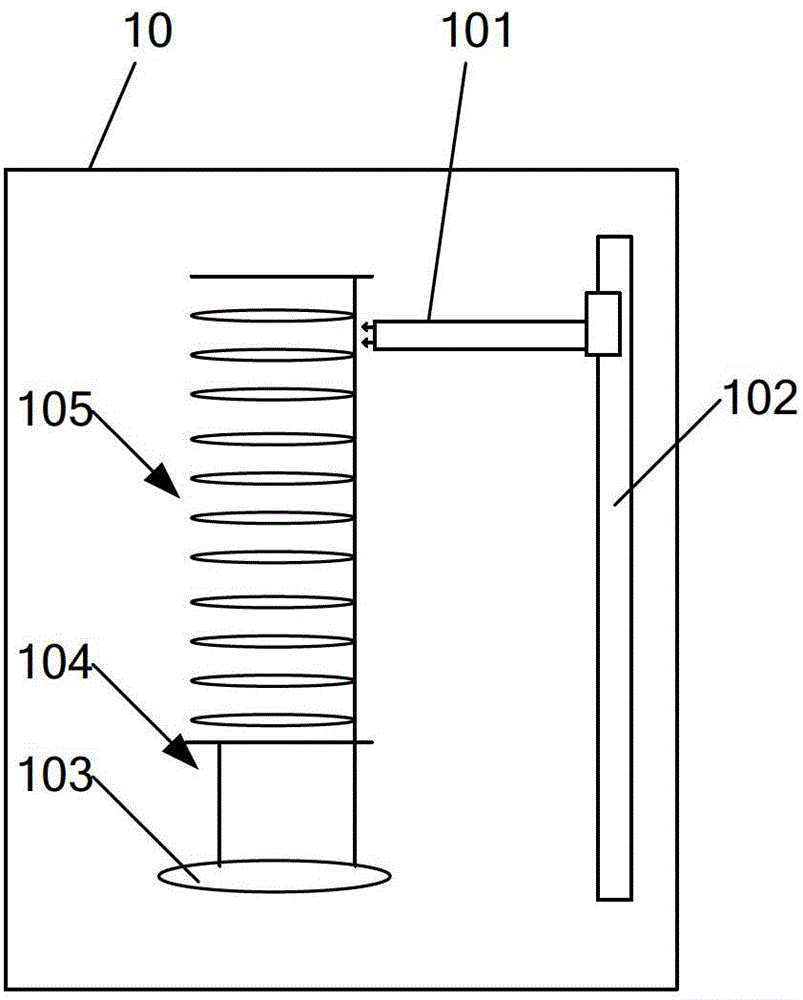

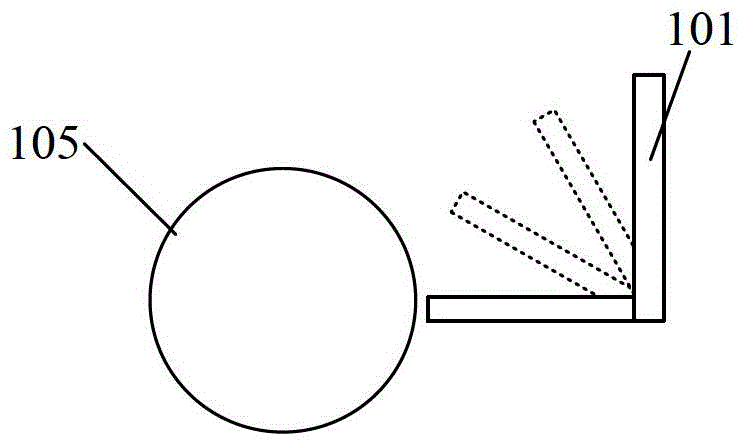

[0017] In the following embodiments of the present invention, the wafer boat automatic purging device is arranged in the loading area in the furnace tube, including: nozzles, guide rails, and purging control structures. The nozzles are used for spraying and purging others to remove residues in the wafer boat tank. The function of automatic cleaning, in the cleaning process, the nozzle can travel along the guide rail; the blowing control structure is used to control the blowing state of the nozzle. This solution automatically realizes the cleaning of residues, avoids manual shutdown and cleaning in the prior art, thereby reducing the production cost of the product and improving the yield o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com