Moveable-type accurately-controllable-temperature full-plastic storage tank rotational moulding device

A mobile and rotomolding technology, applied in the direction of coating, etc., can solve the problems of uneven temperature, inconvenient movement, difficult temperature control, etc., and achieve the effects of ensuring uniformity, convenient cooling, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings and embodiments.

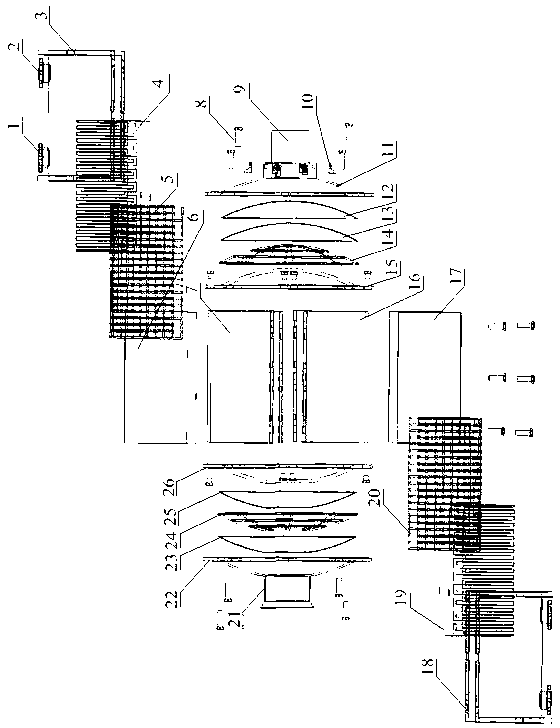

[0029] Such as Figure 2-5 Shown.

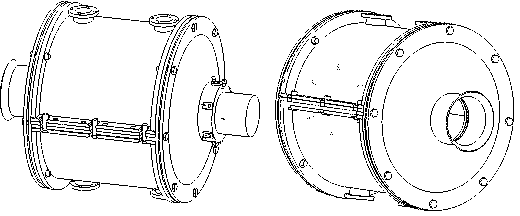

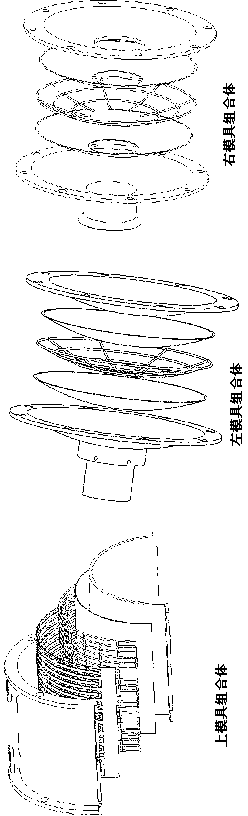

[0030] A movable storage tank rotomolding device that accurately controls the temperature of the mold, with an appearance like figure 1 As shown, it is composed of a mold, a temperature control system, and a power distribution system. The mold is composed of a shell, a heat insulation layer, an electric heating network, a heat conduction layer, and a mold body. The above components can be divided into upper, lower, left and right Four parts, each part is connected by bolts into a whole, such as figure 2 versus image 3 As shown, the four shells are the upper shell 3, the lower shell 18, the left shell 22, and the right shell 11. The four insulation layers are the upper insulation layer 4, the lower insulation layer 19, the right insulation layer 12 and The left insulation layer 13, the four electric heating nets are the upper electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com