Preparation method of flexible self-supported paper graphene membrane and composite membrane thereof

A graphene membrane, self-supporting technology, applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of cumbersome operation, easily damaged membrane structure, unfavorable large-area controllable material preparation, etc., to achieve easy operation, The effect of the simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

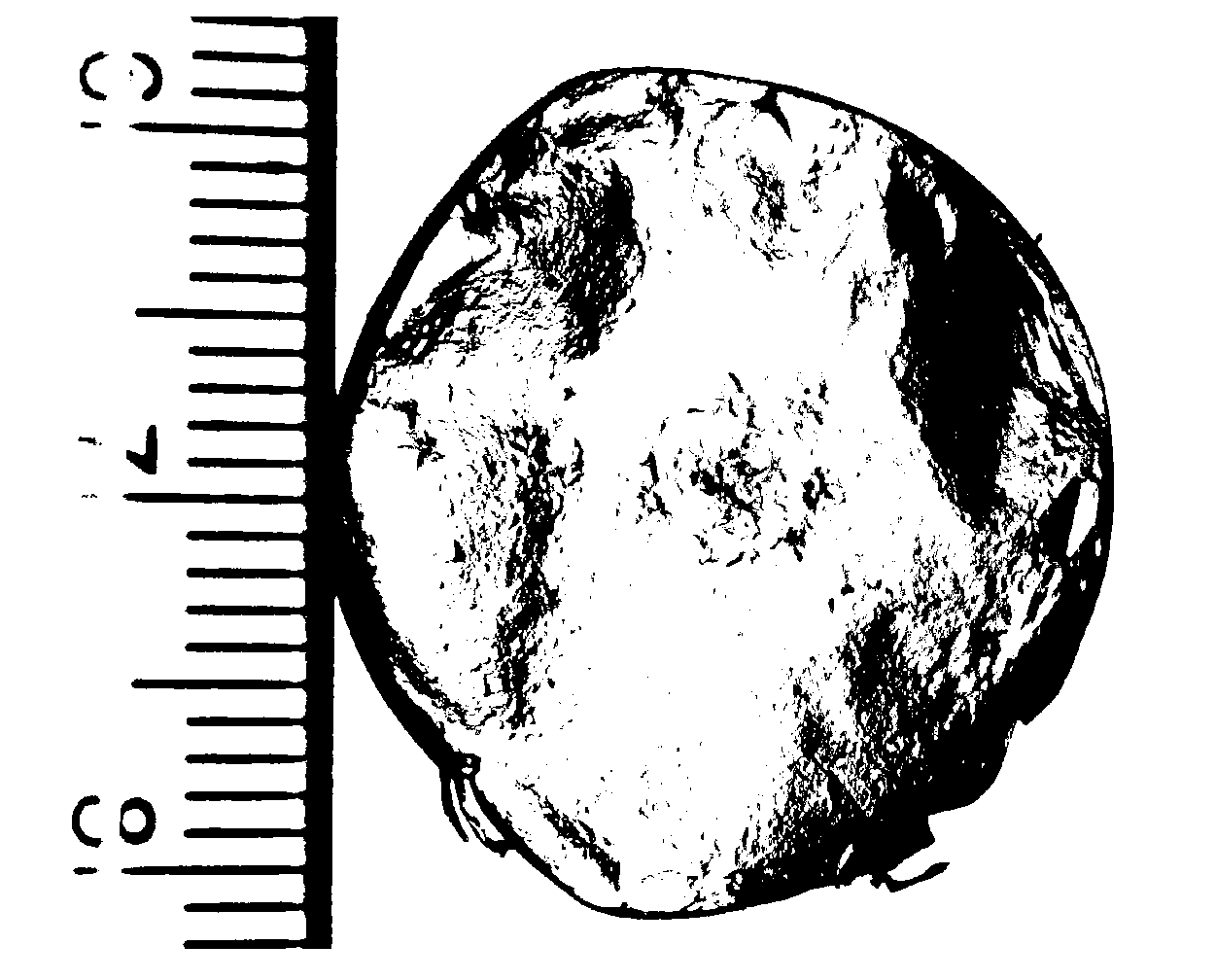

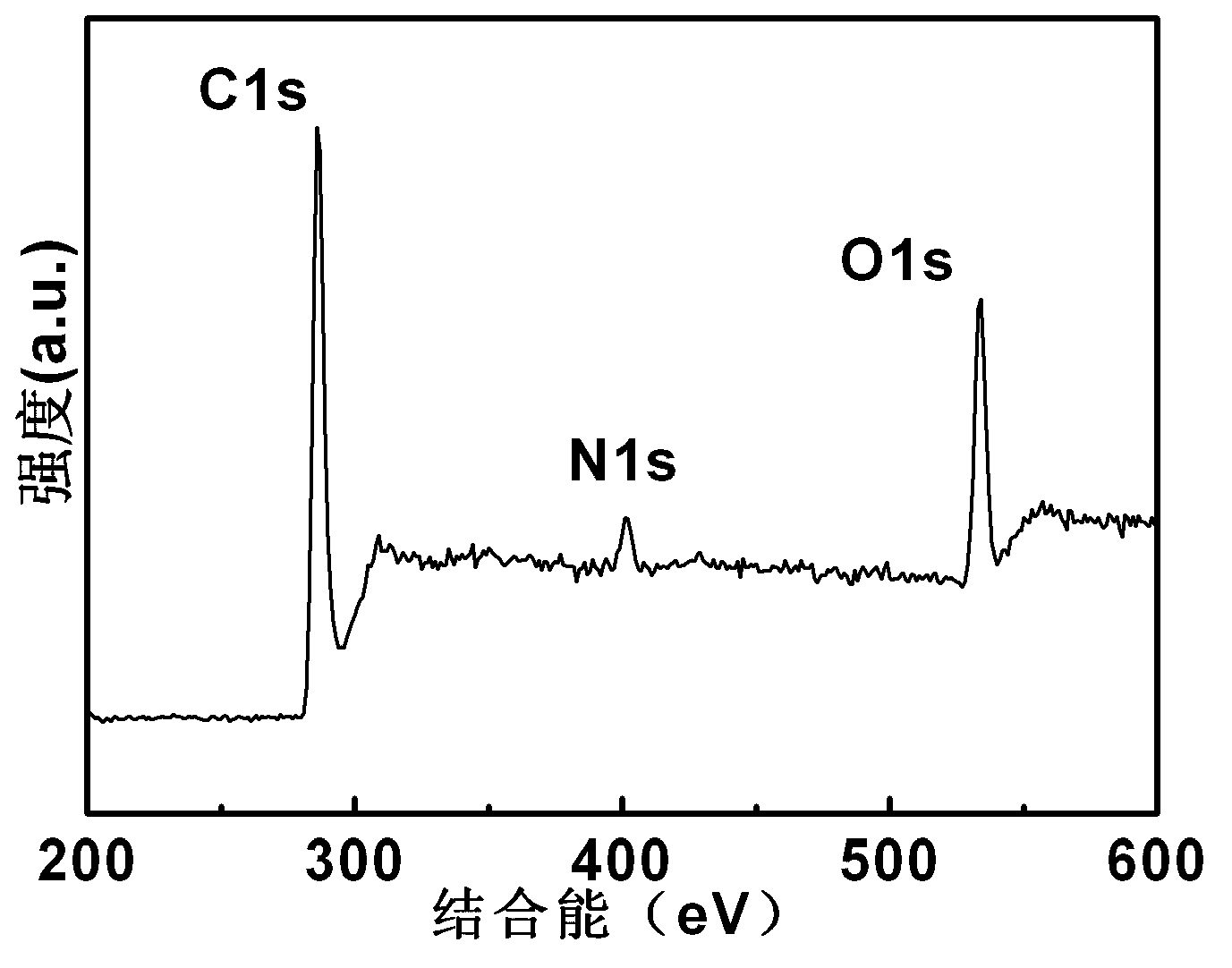

[0030] Example 1. According to the improved Hummers method, graphite was used as raw material to prepare a graphene oxide aqueous solution with a concentration of 7.2 mg / mL. Inject 0.6mL7.2mg / mL graphene oxide aqueous solution into the bottom of 5mL0.4mg / mL hydroxylamine ethanol solution (bottom area is 4.5cm 2 ). After standing for 2 hours, as the distilled water in the graphene oxide layer and the ethanol in the hydroxylamine ethanol solution diffused each other, the hydroxylamine slowly diffused into the graphene oxide layer, and the graphene oxide self-assembled under the induction of hydroxylamine, and solidified to form a yellow-brown oxide layer. Graphene gel such as figure 1 shown. Then slowly increase the temperature to 100°C, keep the temperature, evaporate the solvent, the ethanol solution gradually volatilizes, hydroxylamine reduces the graphene oxide, and at the same time, N elements are doped into the graphene film to prepare a black-gray N-doped self-supportin...

Embodiment 2

[0031] Example 2. According to the improved Hummers method, graphite was used as raw material to prepare a graphene oxide aqueous solution with a concentration of 9.5 mg / mL. Inject 9.5 mL of 7.2 mg / mL GO solution into the bottom of 35 mL of 0.9 mg / mL hydroxylamine ethanol solution (bottom area is 65 cm 2). After standing for 10 hours, as the distilled water in the graphene oxide layer and the ethanol in the hydroxylamine ethanol solution diffused each other, the hydroxylamine slowly diffused into the graphene oxide layer, and the graphene oxide self-assembled under the induction of hydroxylamine, and solidified to form a yellow-brown oxide layer. Graphene gel. Then slowly increase the temperature to 100°C, keep the temperature, evaporate the solvent, the ethanol solution gradually volatilizes, hydroxylamine reduces the graphene oxide, and at the same time, N elements are doped into the graphene film to prepare a black-gray N-doped self-supporting film. The paper-like graphen...

Embodiment 3

[0032] Example 3. According to the improved Hummers method, graphite was used as raw material to prepare a graphene oxide aqueous solution with a concentration of 5 mg / mL. Inject 60 mL of 5 mg / mL GO solution into the bottom of 300 mL of 0.5 mg / mL hydroxylamine ethanol solution (bottom area is 400 cm 2 ). After standing for 6 hours, as the distilled water in the graphene oxide layer and the ethanol in the hydroxylamine ethanol solution diffused each other, the hydroxylamine slowly diffused into the graphene oxide layer, and the graphene oxide self-assembled under the induction of hydroxylamine, and solidified to form a yellow-brown oxide layer. Graphene gel. Then slowly raise the temperature to 90°C, keep the temperature, evaporate the solvent, the ethanol solution gradually volatilizes, hydroxylamine reduces the graphene oxide, and at the same time, N elements are doped into the graphene film to prepare a black-gray N-doped self-supporting film. The paper-like graphene membr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap