A kind of polishing liquid based on metal molybdenum polishing process, its preparation method and application

A technology of polishing liquid and process, which is applied in the field of polishing liquid and polishing liquid of polishing process, can solve the problems of poor efficiency and achieve the effects of low static corrosion rate, high polishing rate and high planarization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

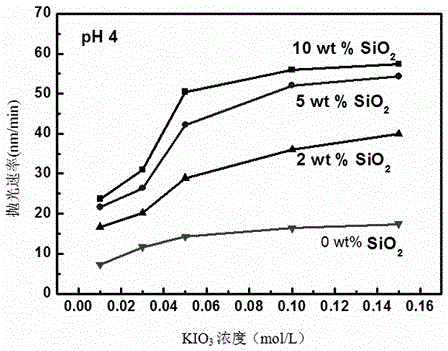

[0032] Preparation of polishing solution: Potassium iodate with a concentration of 0.05 mol / L and 0.1 mol / L; SiO 5% in total weight 2 Abrasives; accounting for 0.05% of the total weight of alkylphenol polyoxyethylene ether and the rest of the water; use diluted nitric acid, potassium hydroxide to adjust the pH value to different pH values. The polishing rate and static corrosion rate of this polishing liquid are as Table 1 and figure 2 shown.

[0033] Polishing equipment and mechanical parameter settings: The polishing machine used in this embodiment is the CP-4 desktop polishing machine produced by CETR Company; the mechanical parameters are set as follows: the pressure is 2psi, the flow rate of the polishing solution is 90ml / min, and the rotational speed of the polishing head is 90rpm. The rotational speed of the polishing table was 90 rpm.

[0034] Table 1: Polishing rate and static corrosion rate of Mo in polishing solutions with different pH values of 0.05 mol / L and ...

Embodiment 2

[0045] Preparation of polishing solution: potassium iodate with a concentration of 0.1 mol / L; SiO in different total weight ratios 2 Abrasives; accounting for 0.05% of the total weight of alkylphenol polyoxyethylene ether and the remainder of water; adjusting the pH value to 4 with diluted nitric acid and potassium hydroxide. The polishing rate of the polishing liquid is shown in Table III.

[0046] The polishing equipment used and process parameters are the same as in Example 1.

[0047] Table 3: The polishing rate of Mo in the polishing liquid containing 0.1 mol / L of potassium iodate and different weight ratios of abrasives

[0048] SiO 2 Abrasive weight ratio (%) 0 2 5 10 Mo polishing rate (nm / min) 16.5 36.4 52.0 55.8

[0049] It can be seen from the data in Table 3 that the polishing rate of Mo is low without adding abrasives. After adding abrasives, the polishing rate increases with the concentration of abrasives. However, when the abrasive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com