Construction method for pre-drilling hole-forming base-expanding and grouting of prestressed concrete special-shaped pile

A special-shaped pile and concrete technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of fast construction period, difficult control of pile quality, large mud discharge, etc., and achieve good pile quality and good social benefits and promotion value, the effect of less mud discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

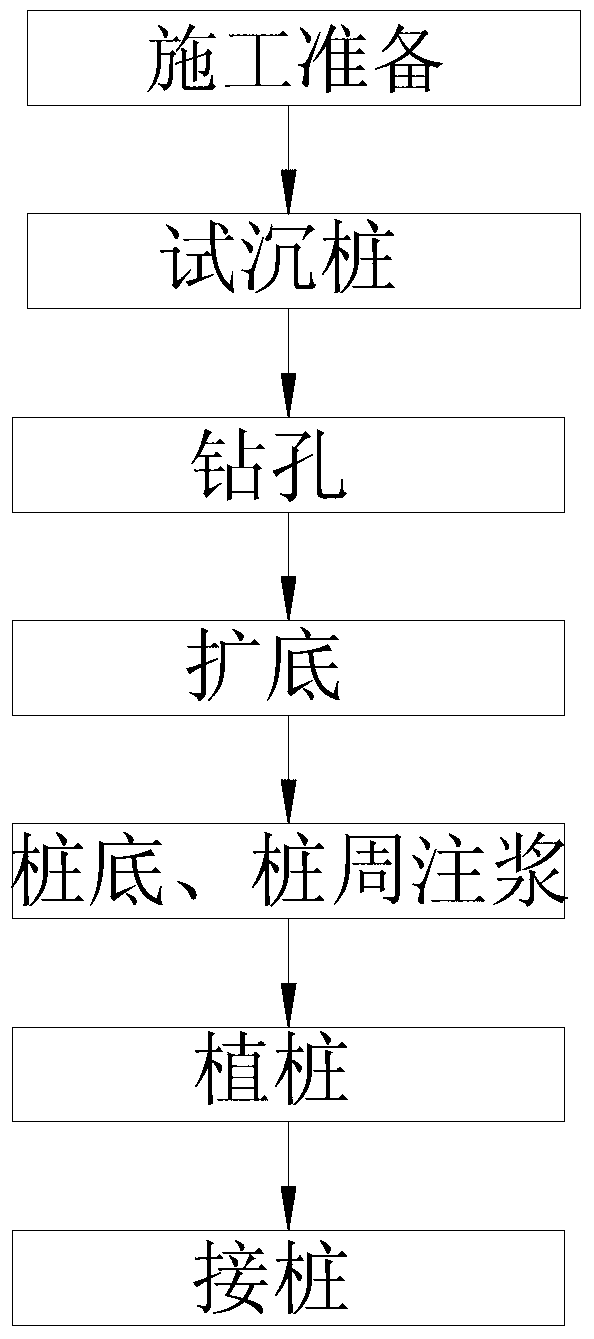

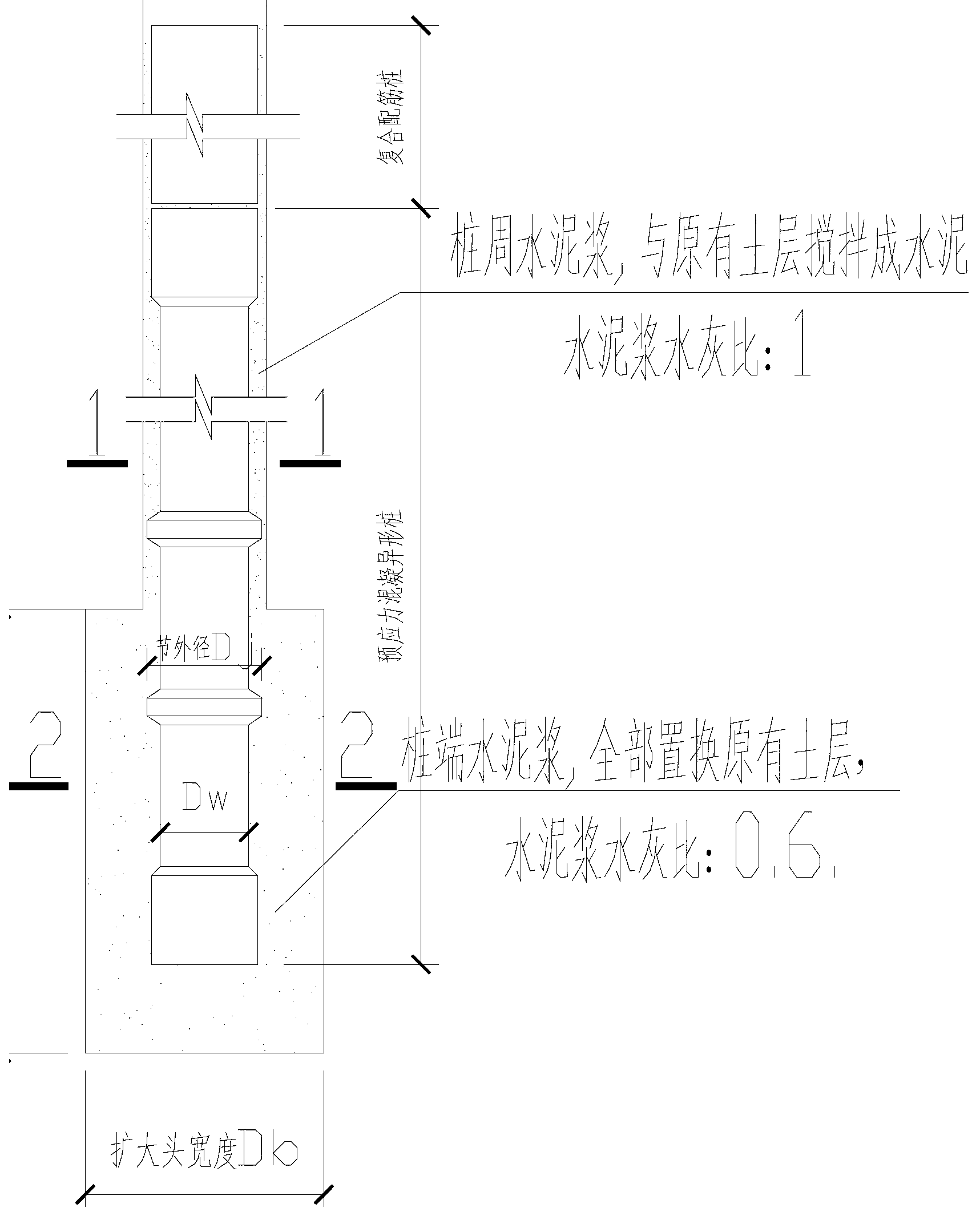

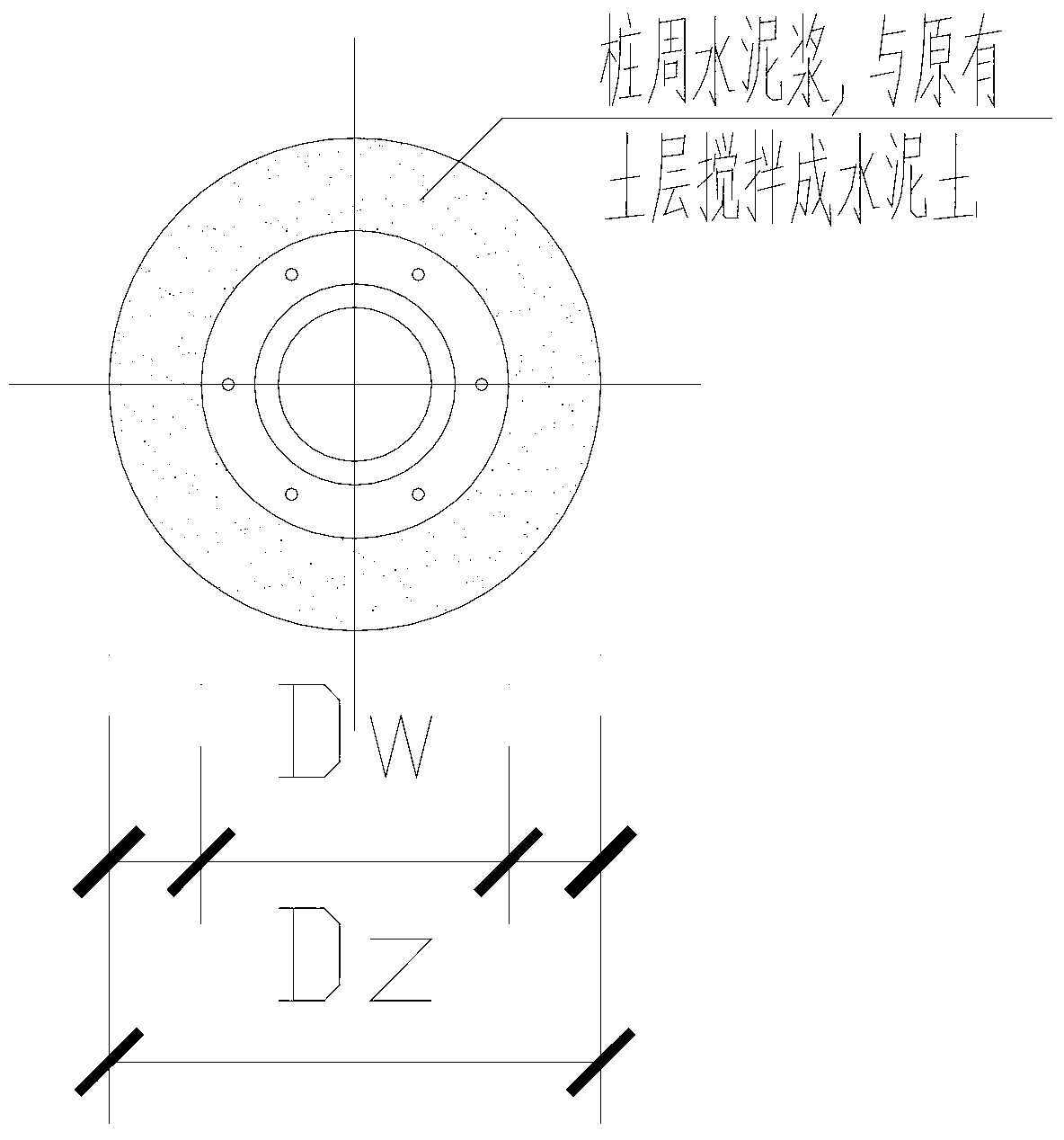

[0026] see Figure 1 to Figure 4 Shown, the operating points of the present invention are as follows:

[0027] 1. Construction preparation

[0028] 1 According to the nature, purpose, scale, construction period, safety and environmental protection requirements of the project, combined with the construction conditions, geological conditions and surrounding environment obtained from the investigation, prepare a separate special construction plan and submit it to the technical director of the enter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap