Connecting structure of circular coal bunker coal retaining wall and coal piling area raft foundation and construction method thereof

A raft foundation and connection structure technology, which is applied in the direction of foundation structure engineering, building structure, and building material processing, can solve the problems of unutilized horizontal bearing capacity of raft piles, increased thickness of raft foundations in coal piled areas, The increase in the amount of raft foundation works and other issues have achieved the effect of reducing the thickness of the raft, good horizontal bearing capacity, and simple construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

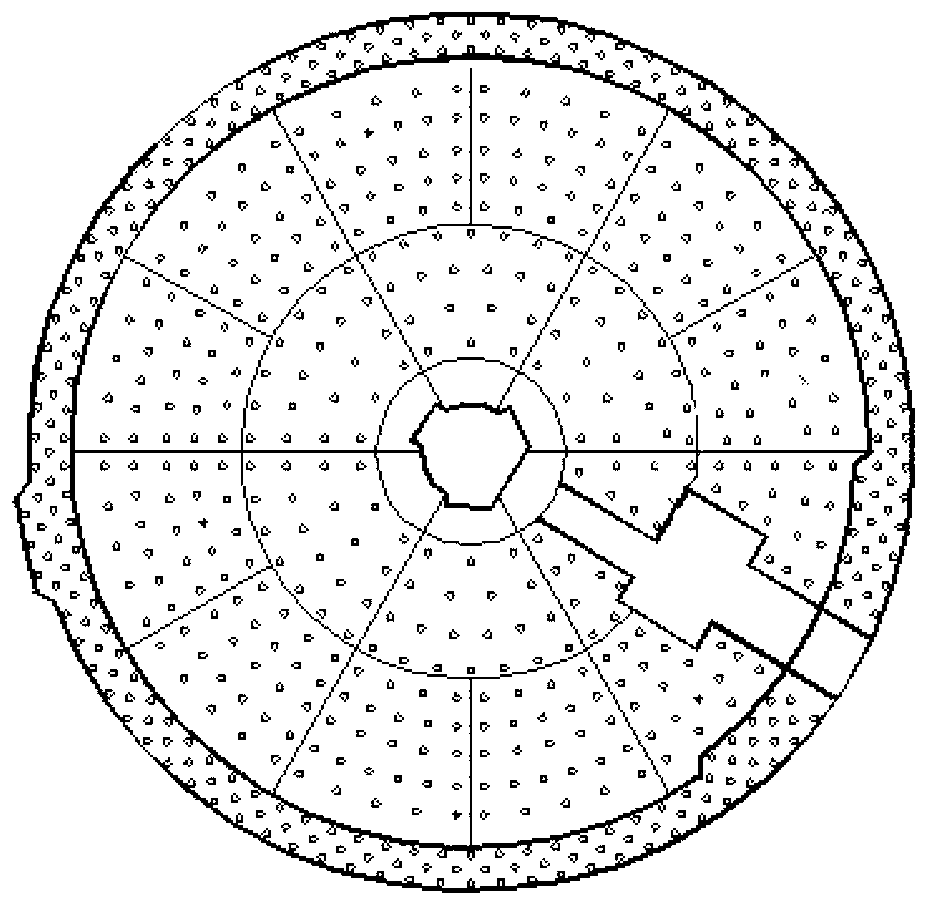

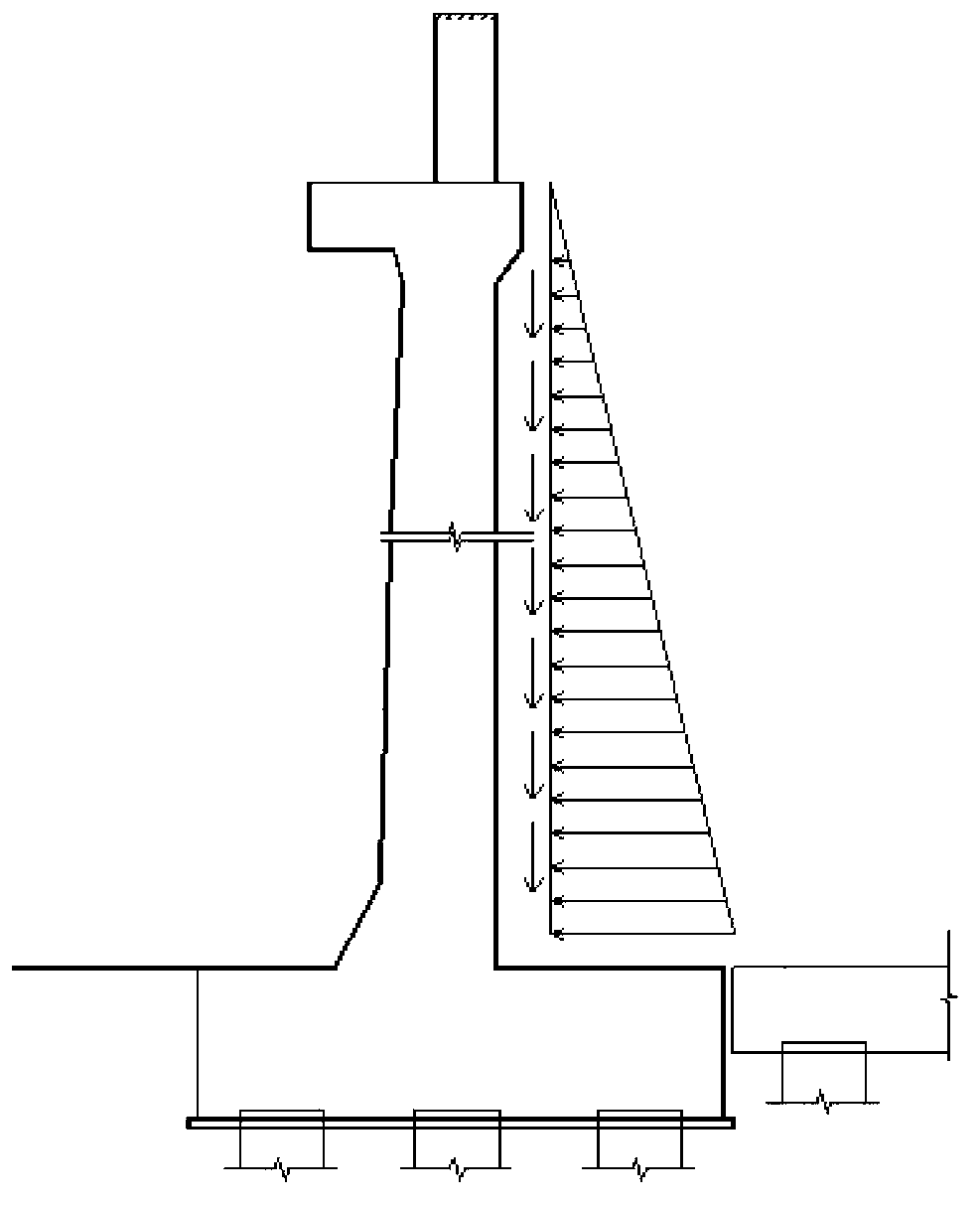

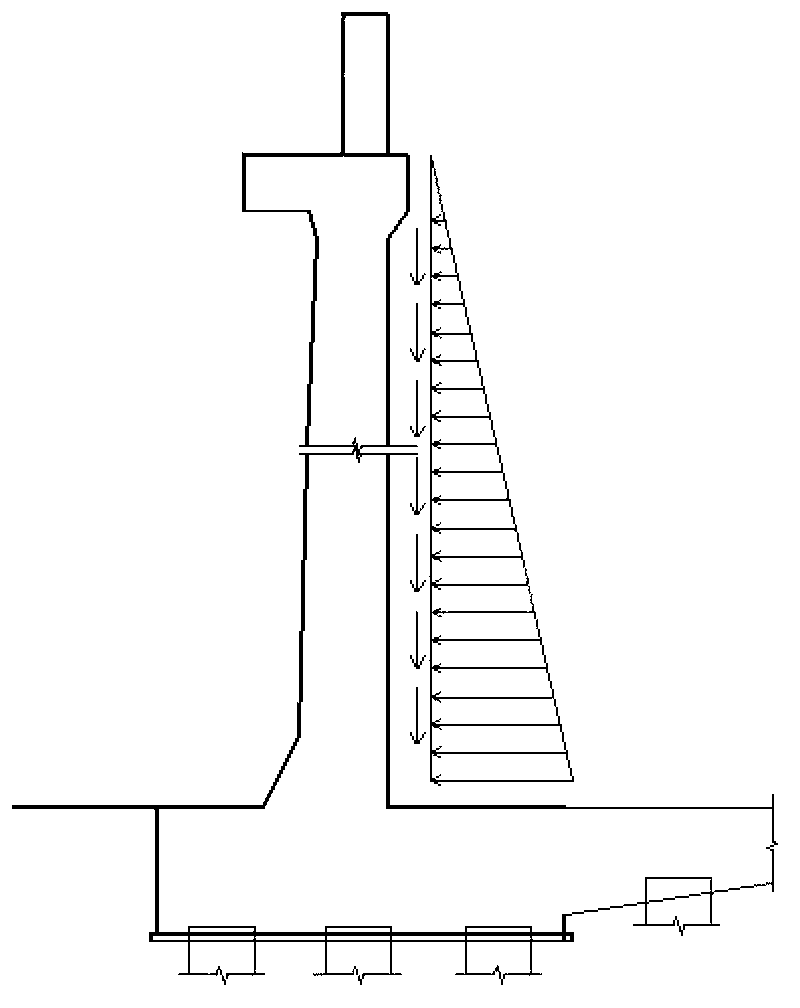

[0030] Such as Figure 4 and Figure 5 The connection structure between the coal retaining wall of the round coal bunker and the raft foundation of the coal pile area shown, including the annular coal retaining wall 3, the annular coal retaining wall foundation 1 and the coal pile area raft foundation 2, in the ring coal retaining wall The inner ring of the foundation 1 is provided with a right-angle convex ring platform 1-1, and the raft foundation 2 in the coal pile area includes a raft area 2-1 and a scarfing part, and the scarfing part of the raft foundation 2 in the coal pile area extends to the annular The coal retaining wall 3 is embedded with the annular coal retaining wall foundation 1, and a recessed ring groove 2-2 is provided on the lower side of the scarfing part of the raft foundation 2 in the coal pile area. The size and shape of the recessed ring groove 2-2 are consistent with The aforesaid right-angle convex ring platform 1-1 coincides with the concave ring g...

specific Embodiment 2

[0036] The characteristics of this embodiment are: in the construction method of the connection structure between the coal retaining wall of the round coal bunker and the raft foundation of the coal pile area, after the concrete strength of the foundation 1 of the annular coal retaining wall reaches 70%, the coal pile is poured District raft foundation 2, other characteristics are identical with specific embodiment 1.

specific Embodiment 3

[0037] The characteristics of this embodiment are: in the construction method of the connection structure between the coal retaining wall of the round coal bunker and the raft foundation of the coal pile area, after the concrete strength of the foundation 1 of the annular coal retaining wall reaches 80%, the coal pile is poured District raft foundation 2, other characteristics are identical with specific embodiment 1.

[0038]The present invention adopts node type connection to insert (interlock) the ring-shaped coal retaining wall foundation 1 and the raft foundation 2 of the coal pile area. The function is similar to that of a column corbel, and they are fastened to each other to achieve the effect of hinge. The nodal connection adopted in the invention makes full use of the horizontal bearing capacity of the foundation pile group composed of raft piles 2-3, thereby reducing the engineering quantity of the annular coal retaining wall foundation 1 and the number of foundation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com