Hydraulic multifrequency dynamic vibration absorber for rotary mechanical rotor

A technology of dynamic vibration absorber and rotating machinery, which is applied in the direction of mechanical equipment, rolling contact bearings, vibration suppression adjustment, etc. It can solve the problems that the real-time online continuous regulation of frequency cannot be realized, and achieve good vibration reduction effect, long service life and reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

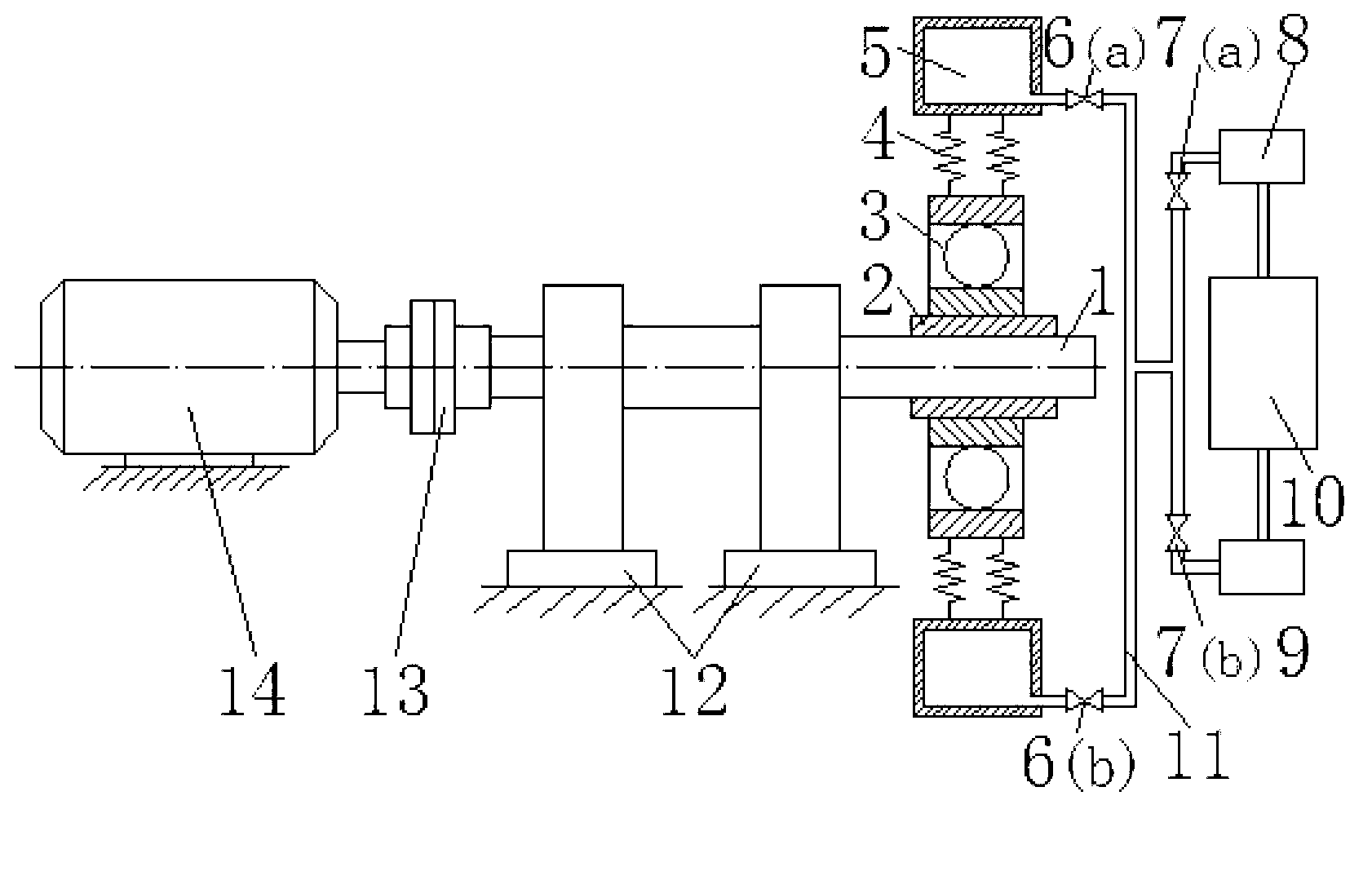

[0040] See attached Image 6 In some occasions, it is necessary to protect the bearing at the support 12 of the rotor system to avoid damage and destruction of the bearing, so it is necessary to install a hydraulic multi-frequency dynamic vibration absorber near the support 12. Give full play to the advantages of flexible and diverse application positions of the vibration absorber of the present invention, install hydraulic multi-frequency dynamic vibration absorbers at two different positions on the rotating shaft 1, that is, on the inner side of the two supports 12, and transfer the vibration energy to the TMD vibration absorber. The vibration of the rotating shaft 1 is reduced to achieve the purpose of protecting the bearing.

Embodiment 2

[0042] See attached Figure 7 , compared with Example 1, there is not enough space between the two supports 12 of some rotating shafts 1 to install the hydraulic multi-frequency dynamic shock absorber, and to achieve the same purpose of protecting the bearing, it can also be installed on the outer side of the two supports 12 . Although the installation position of the hydraulic multi-frequency dynamic vibration absorber is slightly changed, it can also protect the bearing. Therefore, in actual engineering applications, the installation position of the hydraulic multi-frequency dynamic vibration absorber can be flexibly selected according to specific conditions and needs.

Embodiment 3

[0044] See attached Figure 8 , for a flexible rotor with symmetrical applied loads, the midpoint between the two supports 12 has the largest deflection, so the unbalance here is relatively large, and when the rotating shaft 1 rotates, the vibration here will also be relatively large, in order to To reduce the vibration here, a hydraulic multi-frequency dynamic shock absorber can be installed here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com