Engine tensioner and engine

An engine and tensioner technology, applied in mechanical equipment, transmissions, belts/chains/gears, etc., can solve problems such as tensioner function failure, timing system failure, damage to engine parts, etc., to simplify production and assembly process, the effect of avoiding accident damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

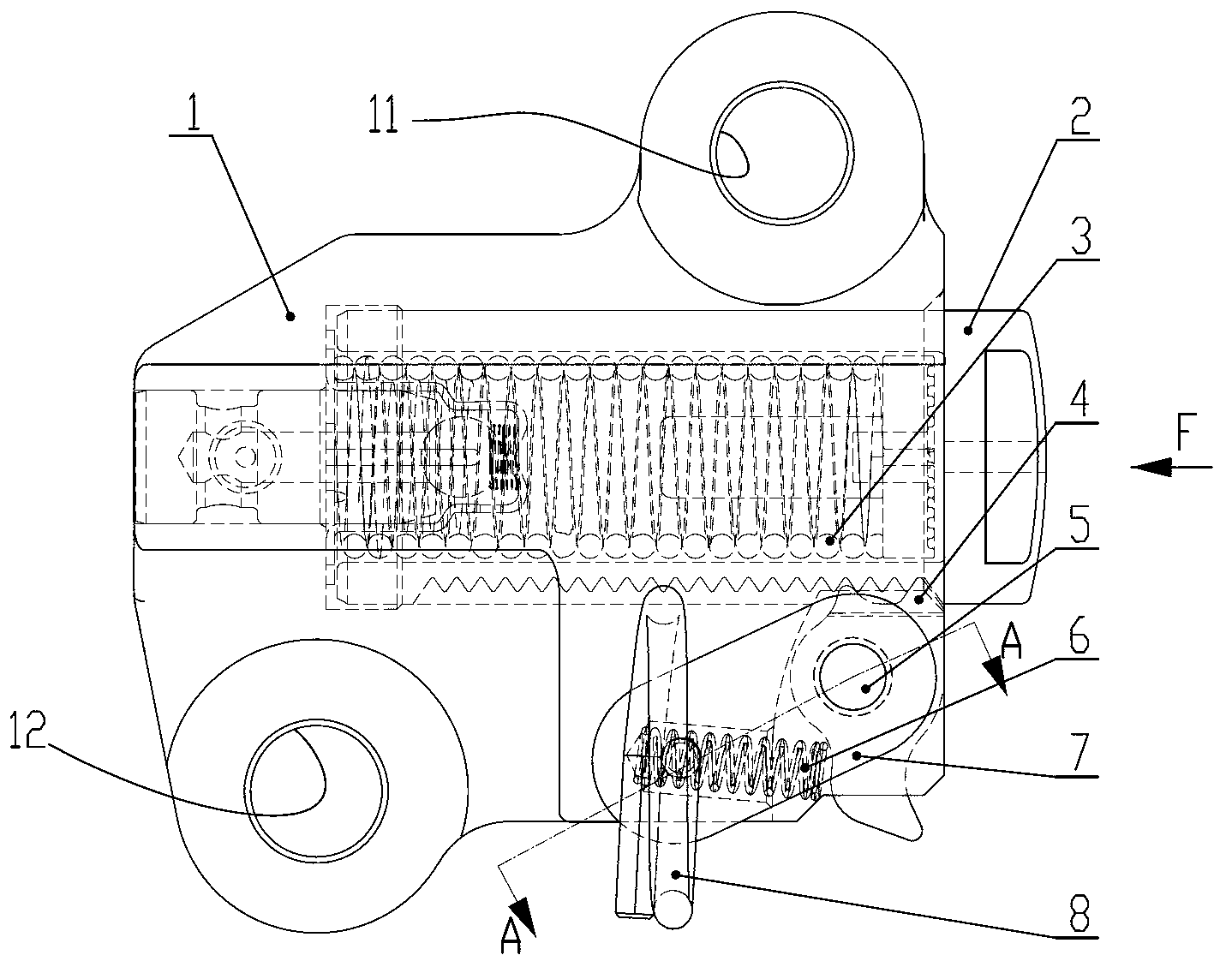

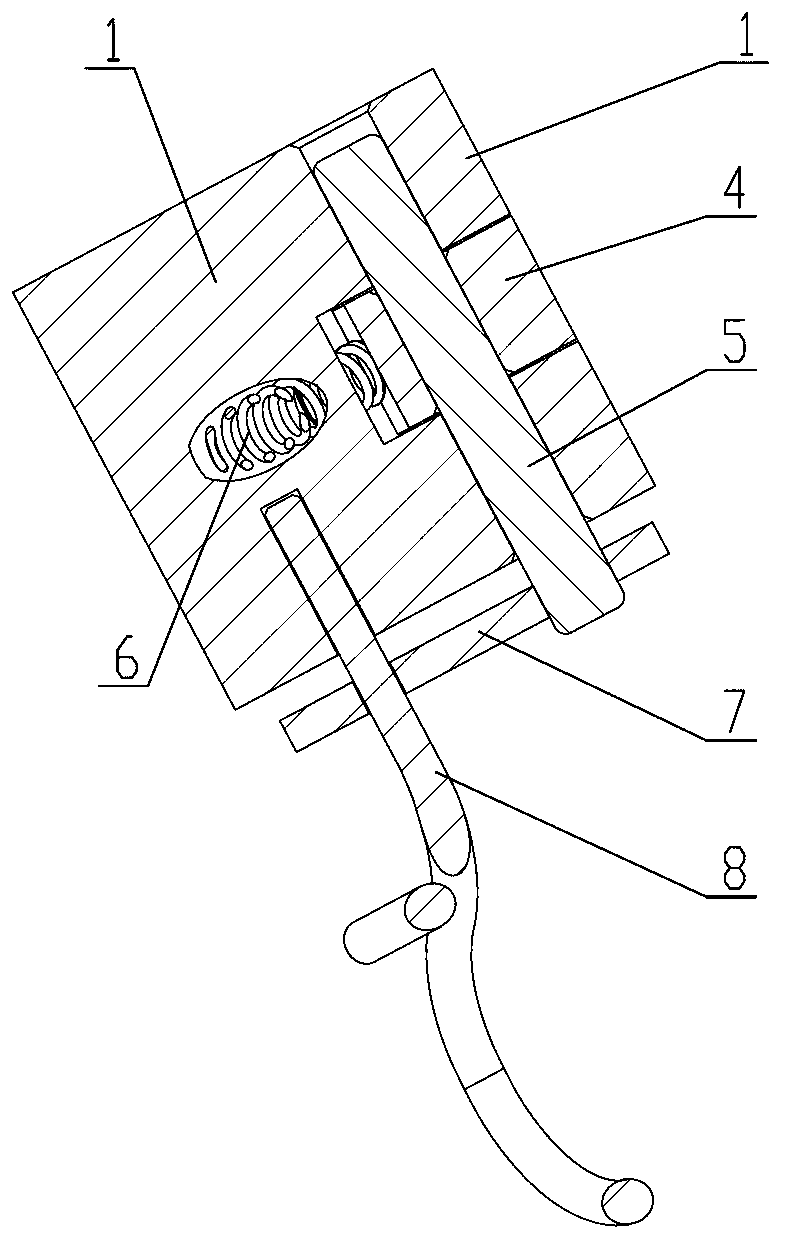

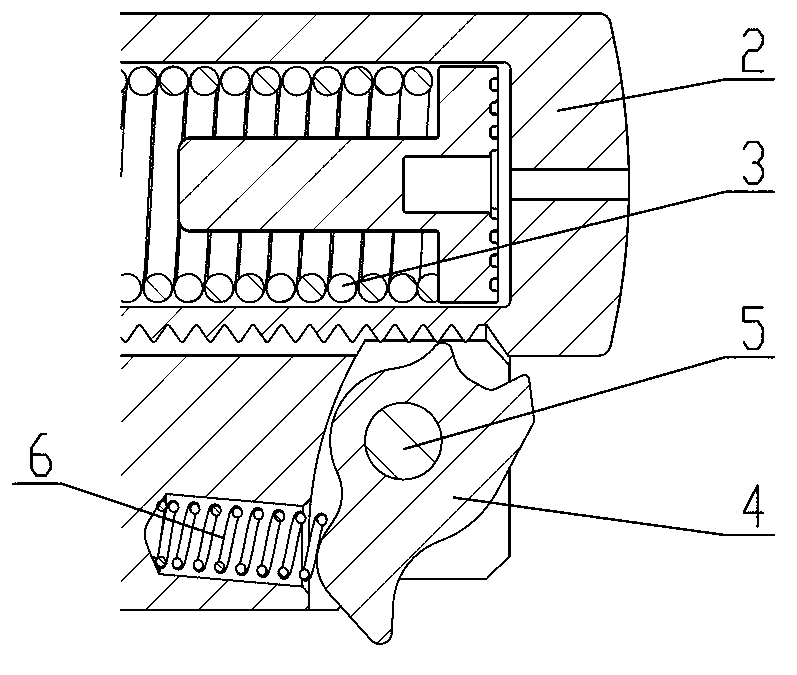

[0026] Such as Figure 5 , Figure 6 , Figure 7 The engine tensioner shown includes a housing 1, a plunger 2, a plunger spring 3, a pawl 4, a pawl pin 5 and a pawl spring 6, and the housing 1 is provided with a The two installation holes installed on the engine, the plunger spring 3 and the plunger 2 are inserted in the plunger hole of the housing 1, the pawl 4 is installed in the pawl groove of the housing 1 through the pawl pin 5, and the pawl The ratchet end of 4 can be engaged with the tooth groove on the plunger 2, the non-ratchet end of the ratchet 4 is against the ratchet spring 6, and the ratchet spring 6 is arranged in the ratchet spring hole of the housing 1, the ratchet Near the non-ratchet end of the pawl 4, a retaining pin 9 that limits the range of rotation of the pawl 4 is installed. The tooth grooves are engaged to limit the outward movement of the plunger 2. The retaining pin 9 is inserted in the retaining pin hole of the housing 1, and a positioning pin 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com