Drive circuit suitable for silicon controlled rectifier of rectifier circuit of frequency converter

A technology for rectifying circuits and driving circuits, applied in the field of circuits, can solve problems such as complex installation, and achieve the effects of reducing losses, reducing the cost of the whole machine, and simplifying the production and assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

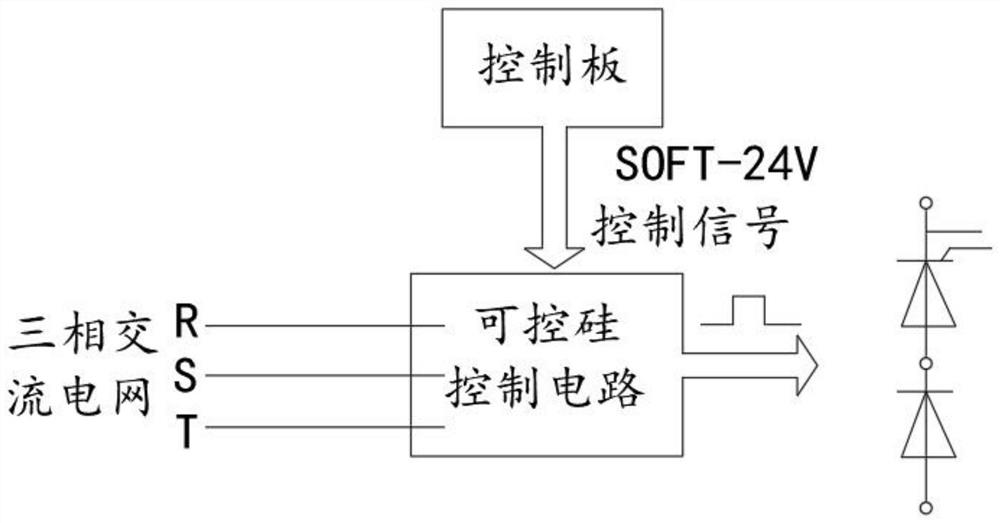

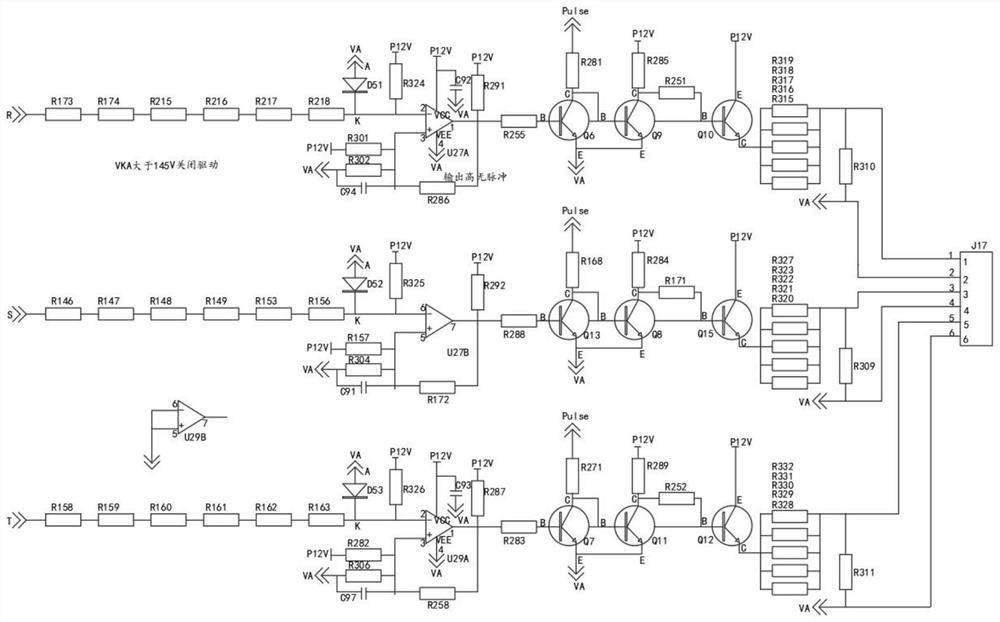

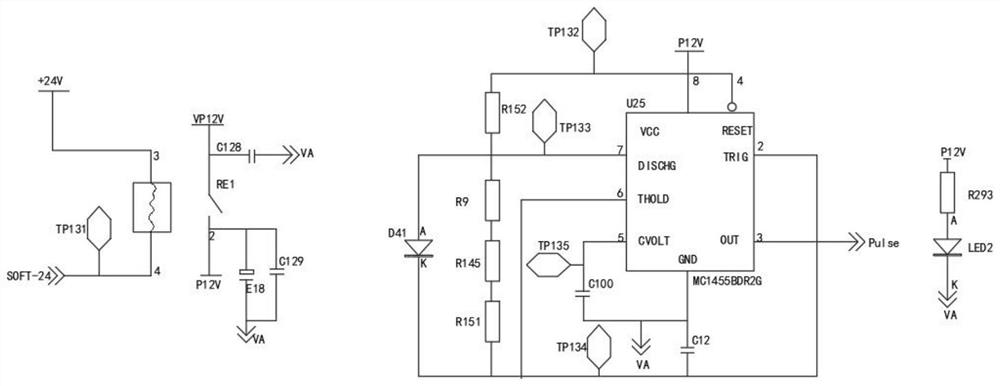

[0022] Such as figure 1 As shown, a drive circuit suitable for the thyristor of the inverter rectifier circuit, the circuit includes:

[0023] The thyristor control circuit controls the on and off of the diode according to the phase of the input AC voltage;

[0024] The control board controls the signal of the thyristor control circuit through the SOFT control signal;

[0025] The R-phase circuit is controlled by the thyristor control circuit as a whole to ensure that the gate of the thyristor has received the pulse driving voltage before the sine wave voltage crosses zero, avoiding the large loss and heat generation caused by high reverse voltage;

[0026] The S-phase circuit is controlled by the thyristor control circuit as a whole to ensure that the gate of the thyristor has received the pulse driving voltage before the sine wave voltage crosses zero, which avoids the great loss and heat generation caused by high reverse voltage;

[0027] The T-phase circuit is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com