Self-pumping fluid-dynamic-pressure-type mechanical seal

A fluid dynamic pressure, mechanical seal technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the complex structure of the sealing end face of the double-row spiral groove mechanical seal, the poor anti-particle interference ability, and the small opening force of the sealing end face. and other problems, to achieve the effect of superior sealing performance, reducing operating costs, and avoiding abrasive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

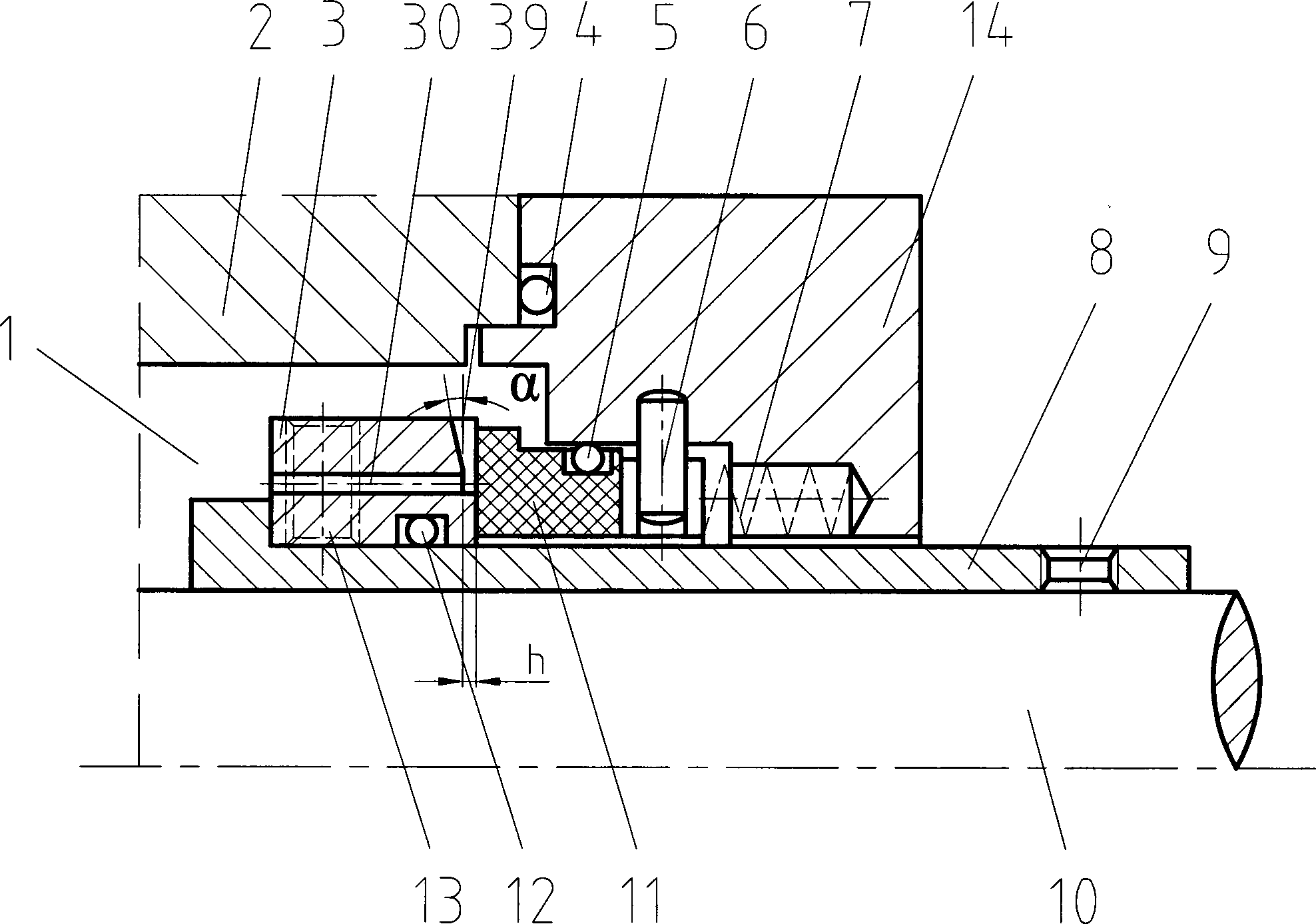

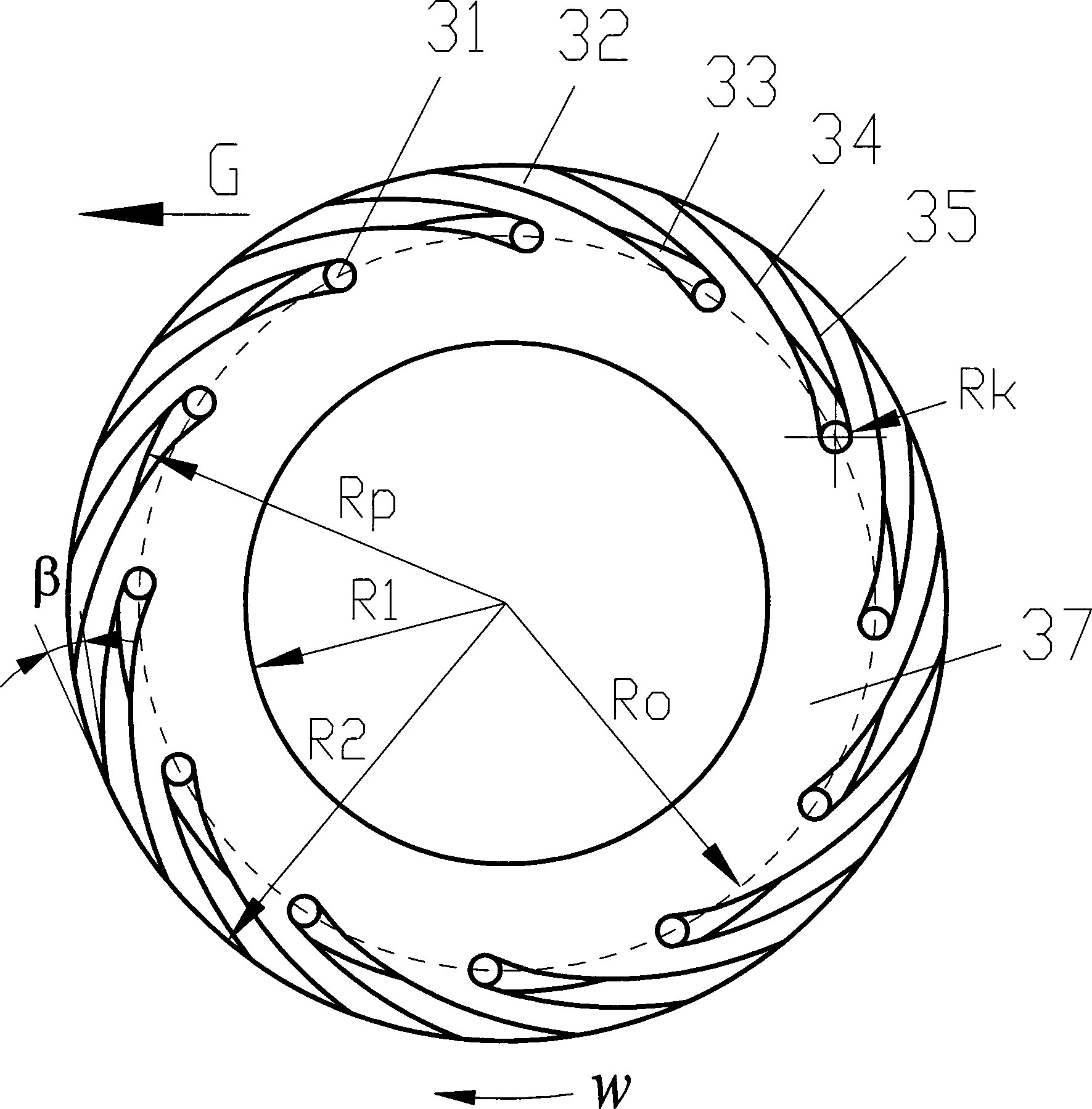

[0049] figure 1 with figure 2 A self-pumping fluid dynamic pressure mechanical seal is described, which is arranged between the casing 2 of the rotating machine and the shaft 10 or the sleeve 8, and consists of a moving ring 3, an O-ring 12 for the moving ring, a static ring 11, The static ring is composed of an O-ring 5, a spring 7, and a static ring seat 14; On the outer part of the end face; 12 sets of back-curved fluid-type grooves 39 are set in the groove area, and the sealing surface between the backward-curved fluid-type grooves 39 forms a sealing weir;

[0050] The back-curved fluid groove 39 includes two parts: a slope groove 32 and a flat groove 33. The slope groove 32 is located at the large radius portion of the end face of the moving ring, and the flat groove 33 is located at the small radius portion of the end face of the moving ring;

[0051] The outlet of the back-curved fluid groove 39 is located at the outer diameter of the moving ring sealing surface, the...

Embodiment 2

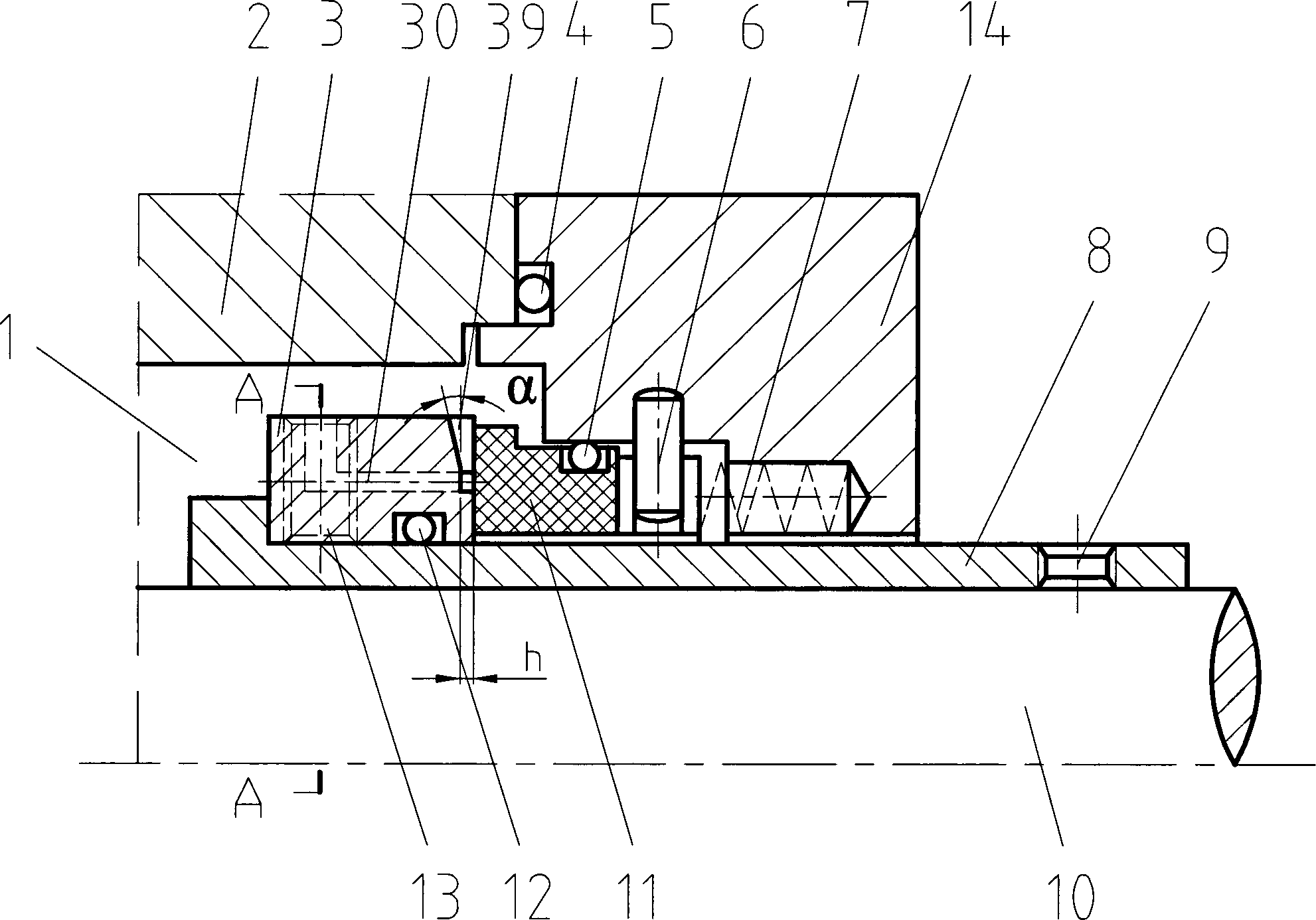

[0059] Figure 3 to Figure 5 It is another self-pumping hydrodynamic mechanical seal, the difference from Embodiment 1 is that the inlet 31 of the backward-curved fluid groove 39 in this embodiment and the circular seal set in the middle of the sealing surface of the moving ring 3 The ring groove 36 is connected, and the circular ring groove 36 is provided with 6 axial and radial combination channels 30 communicating with the sealing chamber 1; The cross-section of the joint of the surface is a wedge-shaped opening 38; the circular ring groove 36 has the functions of collecting self-lubricating, self-flushing medium and preventing the pumping medium from being uneven and the fluid replenishment at the inlet 31 of the back-curved fluid type groove 39 is not timely Cavitation occurs.

[0060] The rest of the structures and implementations are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com