Tube type heat collector capable of efficiently collecting heat

A tube-type heat collector and heat-collecting tube technology, which is applied to solar heat collectors, solar heat collectors using working fluids, heating devices, etc., can solve problems such as low heat collection efficiency, low thermal efficiency, and insufficient heat collection efficiency. Achieve system stability, prolong service life, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

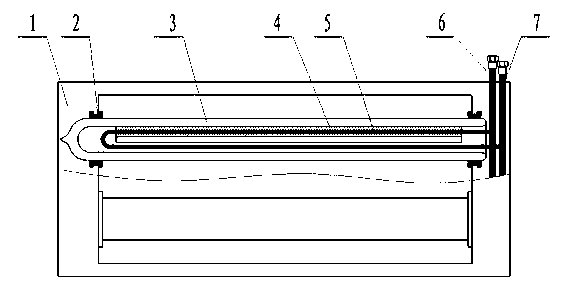

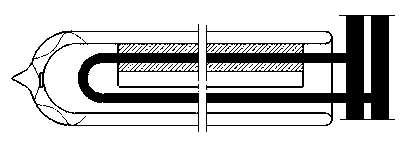

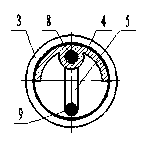

[0012] Such as figure 1 , figure 2 , image 3 As shown, the present invention relates to a high-efficiency heat-collecting tubular heat collector, including a heat collector frame, a vacuum tube, a U-shaped heat-collecting tube, metal fins, a medium circulation inlet and outlet, a medium heat-collecting inlet, a sealing ring, and a heat-collecting A vacuum tube 3 is installed in the collector frame 1, and the vacuum tube 3 is connected to the collector frame 1 through a sealing ring 2. The vacuum tube 3 is inserted with a stainless steel U-shaped heat collecting tube 5, and the U-shaped heat collecting tube 5 and the heat pipe 8 are inserted with metal fins 4 and metal fins. 4 Close to the inner tube wall of the vacuum tube 3, the two ends of the U-shaped heat collecting tube 5 are respectively connected to the medium heat collecting outlet 6 and the medium heat collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com