Vertical and horizontal dual-purpose special angle head suitable for special machining

A vertical and horizontal dual-purpose, special angle technology, used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of semi-finishing of molds, small tools, deep cavity and other problems, achieving small size and saving Tool cost, the effect of large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

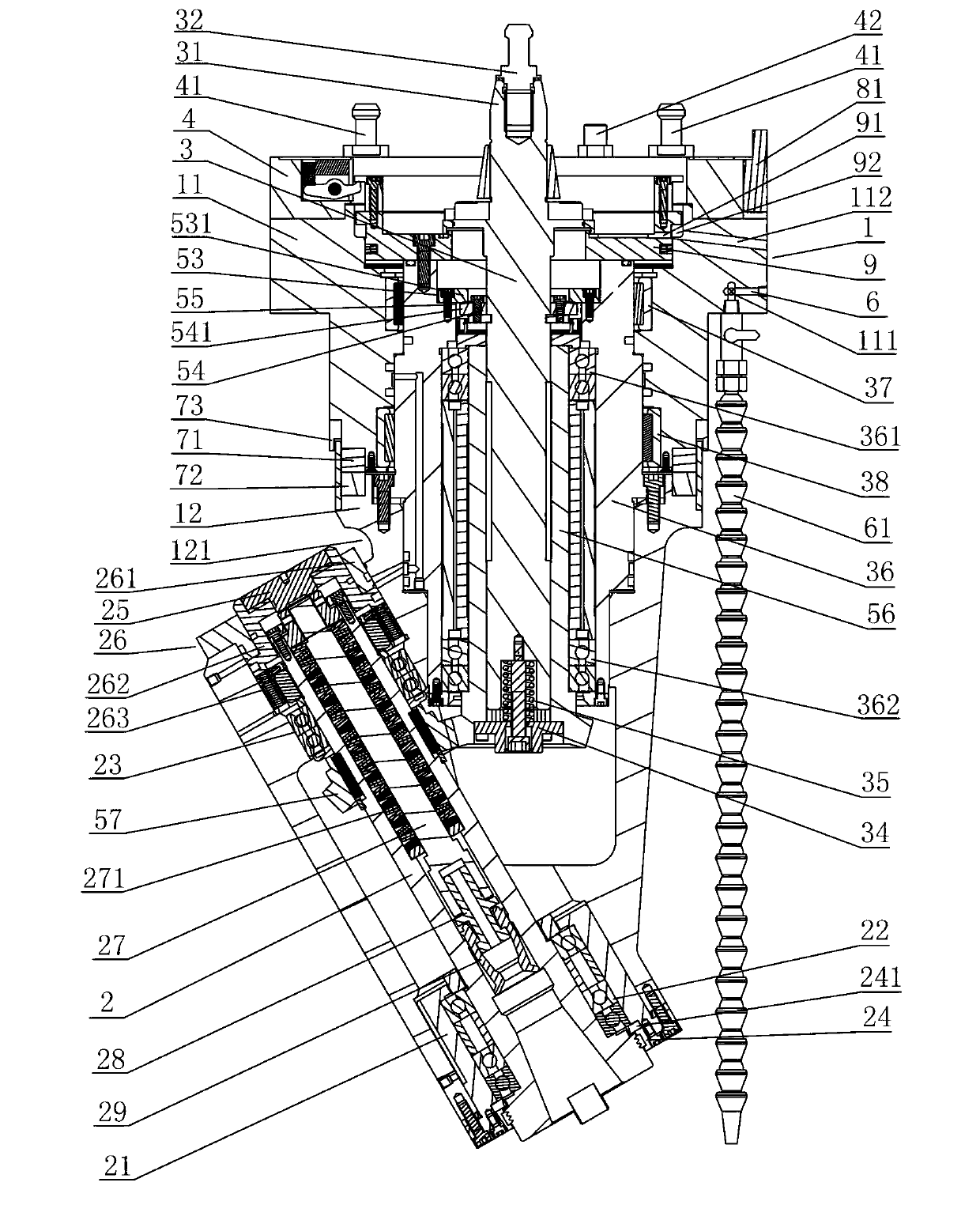

[0017]As shown in the figure, a vertical and horizontal dual-purpose special angle head suitable for special processing includes a box body 1, a main shaft 2, a transmission shaft 3 and a transmission mechanism 5 arranged between the box body 1 and the main shaft 2; the box body 1 is composed of The upper box body 11 and the lower box body 12 are composed. The upper end of the upper box body 11 is fixedly connected with the connecting body 4. The connecting body 4 is provided with a plurality of pull studs 41 and quick-plug joints 42. The connecting body 4 passes through a plurality of pull studs 41 It is connected with the oil receiving tray 8 of the ram (not shown in the figure); a tooth plate 7 is arranged between the upper box body 11 and the lower box body 12, and the tooth plate 7 is composed of an upper tooth plate 71 and a lower tooth p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com