Assembling automatic production line for electric detonator

An automated production line and electric detonator technology, applied in detonators, assembly machines, metal processing equipment, etc., can solve problems such as backward technology, achieve the effects of reducing production costs, overcoming safety hazards, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

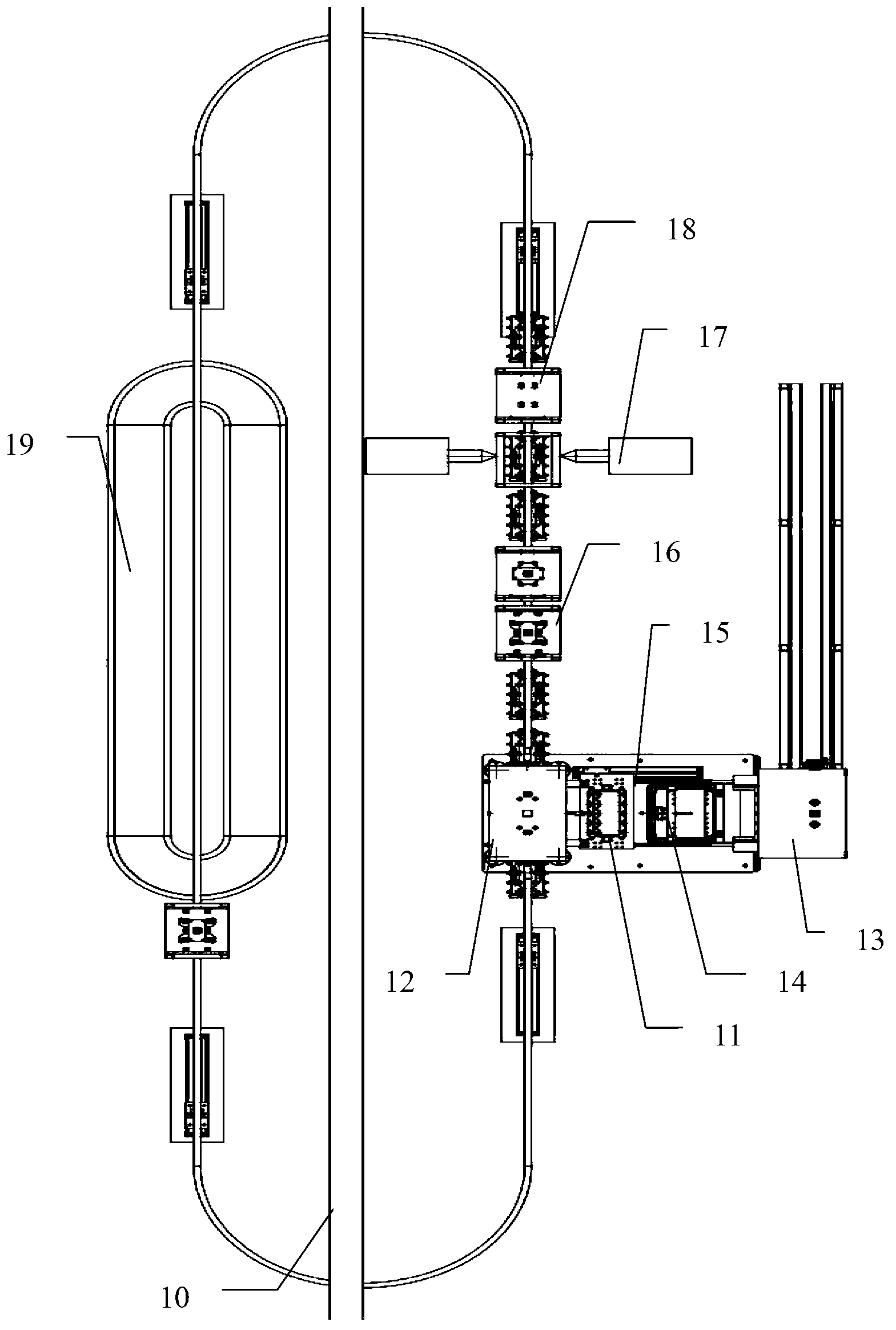

[0030] The invention provides an electric detonator assembly automation production line, such as figure 1 shown, including:

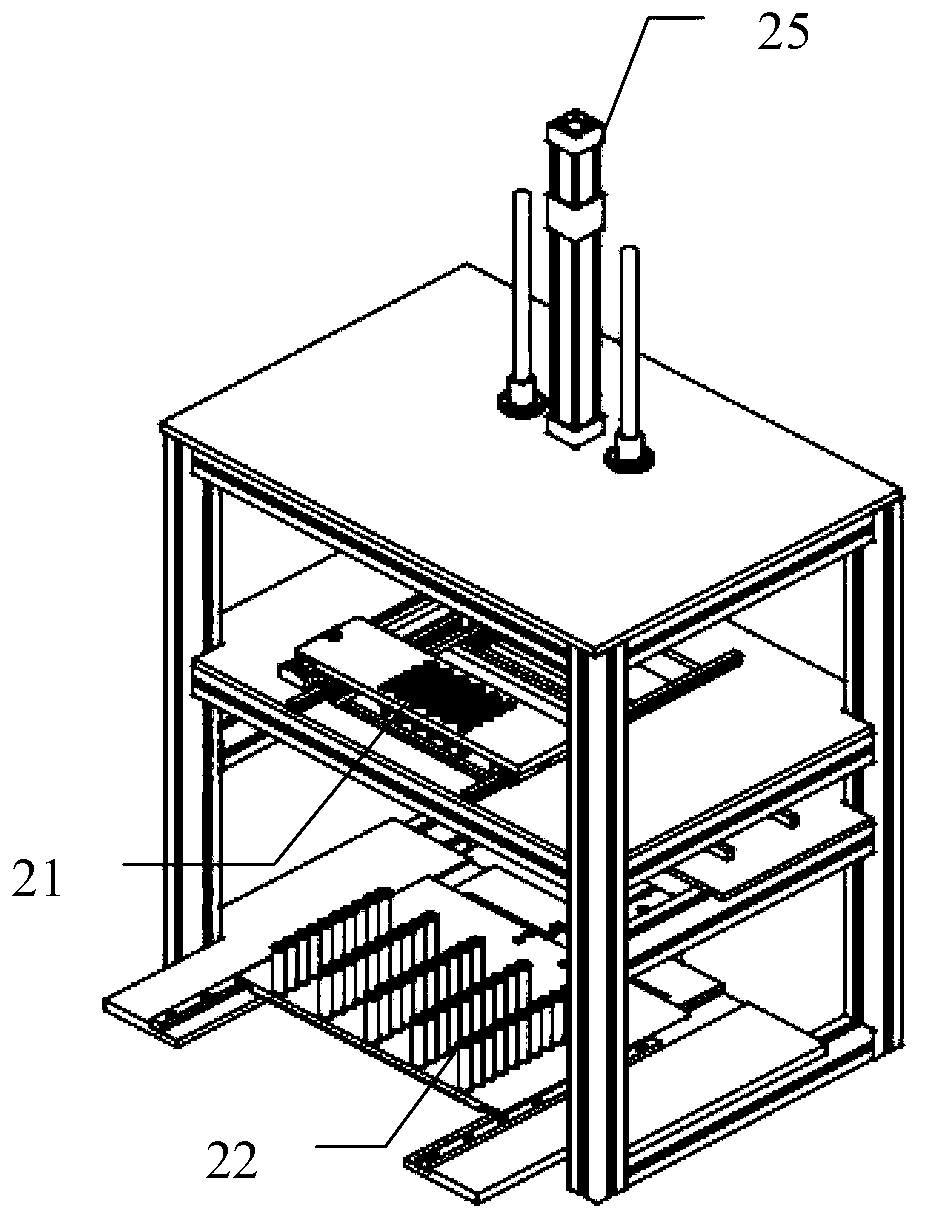

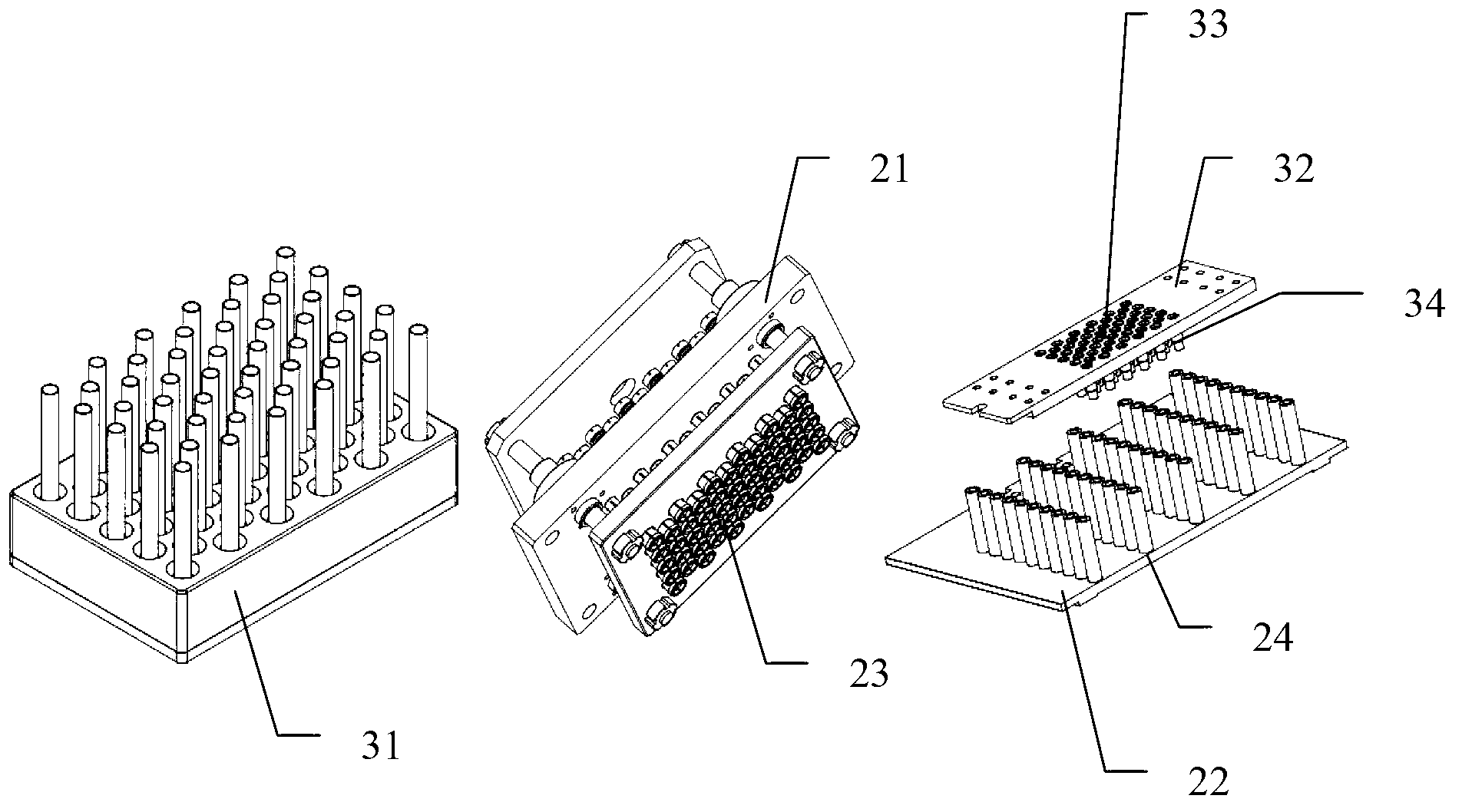

[0031] Step 1. Pack the electric ignition elements to be assembled into the first manipulator and send them to the first-level assembly station 11. The first manipulator is installed on the circular closed track, and the middle of the closed track is separated by the explosion-proof wall 10. The operation safety area and the assembly operation danger area, until the whole process of assembly operation is completed and the unloading station is unloaded, then return to the manual operation safety area to cycle. 14. The reclaiming station 15 is sent to the first-level assembly station to be assembled with the electric igniter to be assembled, and the ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com