Optical fiber end face processing method and optical fiber connector

An optical fiber end face treatment and connector technology, which is used in the coupling of optical waveguides, grinding devices, grinding machine tools, etc., can solve problems such as poor fiber end face cutting, and achieve the effect of solving poor cutting, improving connection performance, and ensuring sufficient docking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

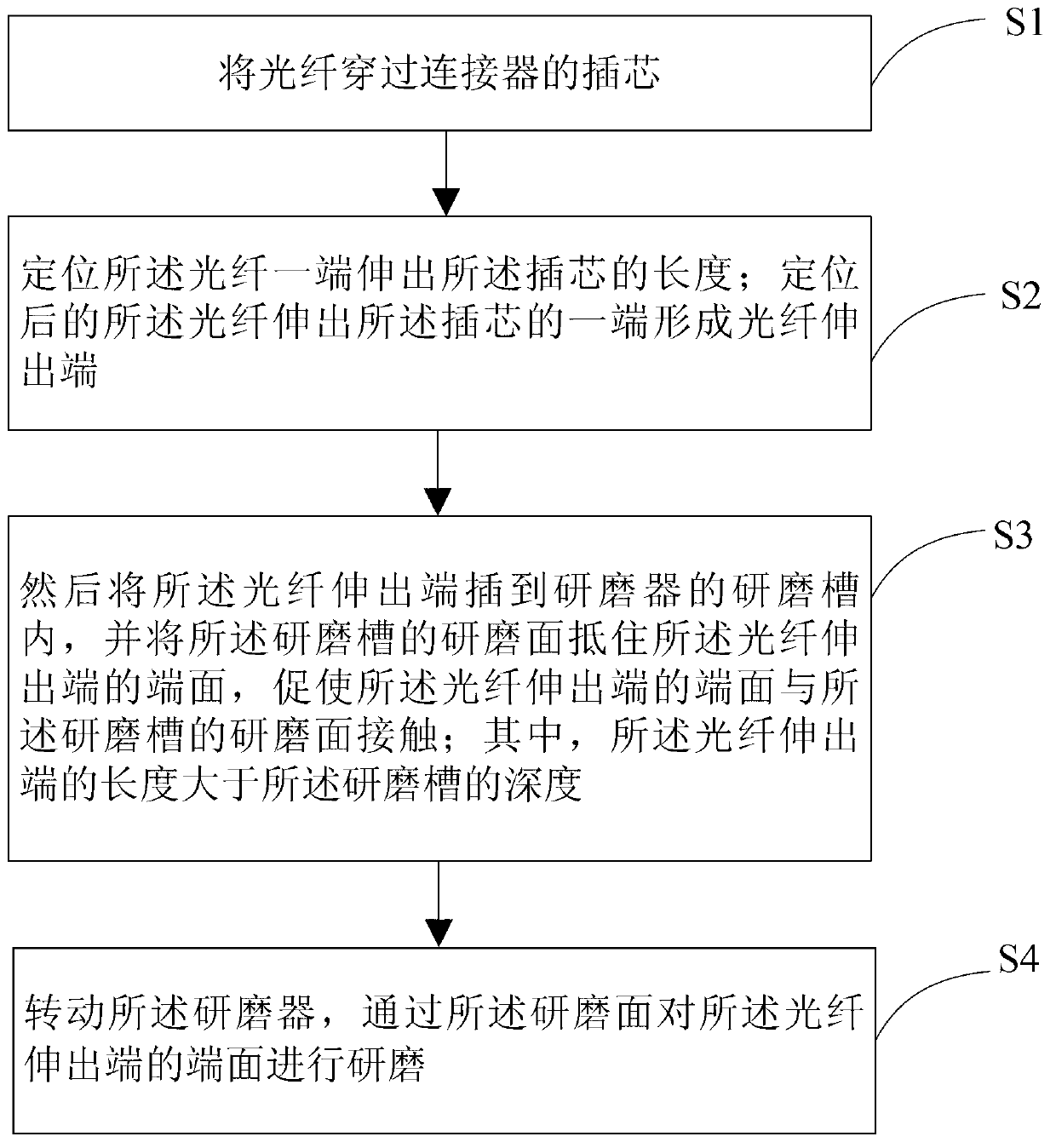

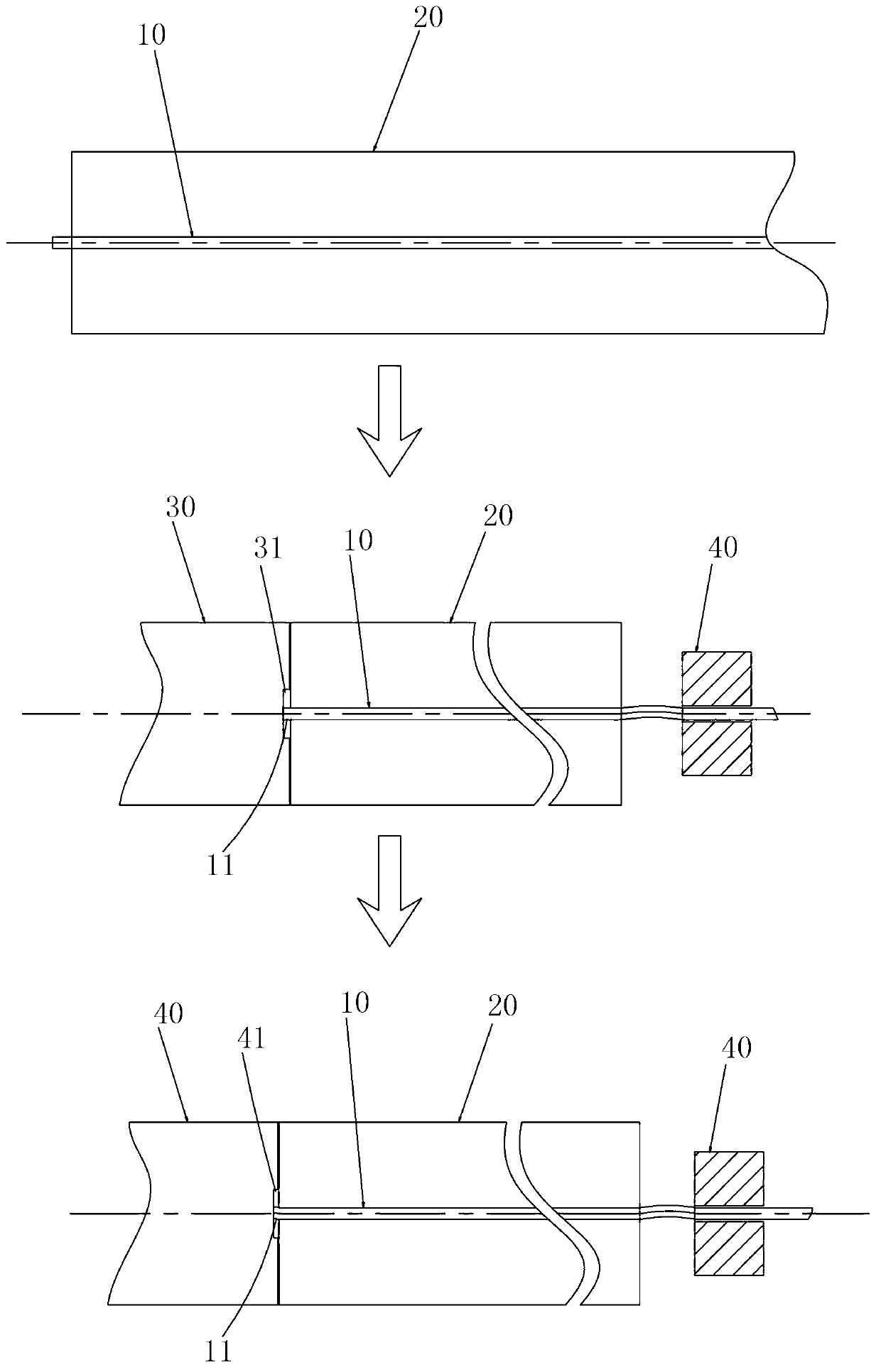

[0024] Such as figure 1 As shown, it is a schematic flow chart of an optical fiber end face processing method according to an embodiment of the present invention, combined with figure 2 , the optical fiber end face processing method comprises the following steps:

[0025] S1. Pass the optical fiber 10 through the ferrule 20 of the connector. Wherein, the optical fiber 10 is pre-cut to a fixed length, and then passed into the ferrule 20 after cutting. After the optical fiber 10 passes through the ferrule 20 , one end of the optical fiber 10 can extend out of the ferrule 20 , and the protruding length is preferably less than or equal to 10 mm. The ferrule 20 of the connector is a ceramic ferrule or a metal ferrule or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com