Sheet metal parts rapid prototyping equipment

A technology for forming equipment and sheet metal parts, which is applied in the field of rapid prototyping equipment for sheet metal parts, and can solve problems such as failure to work normally, dead spots, and affecting equipment utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

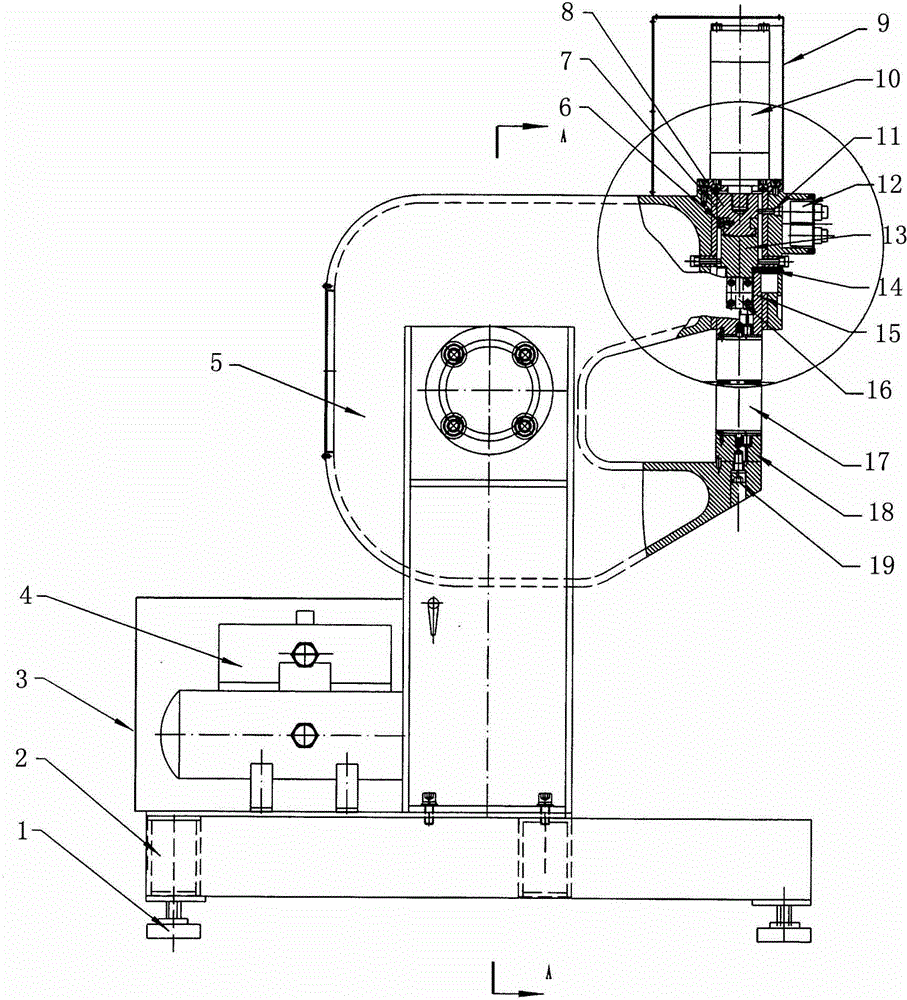

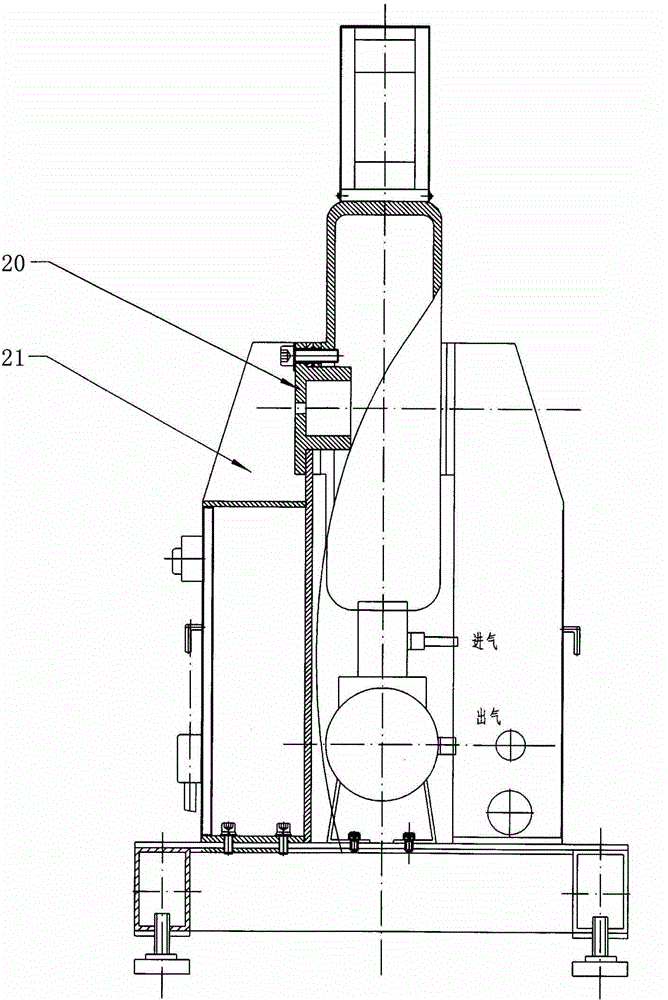

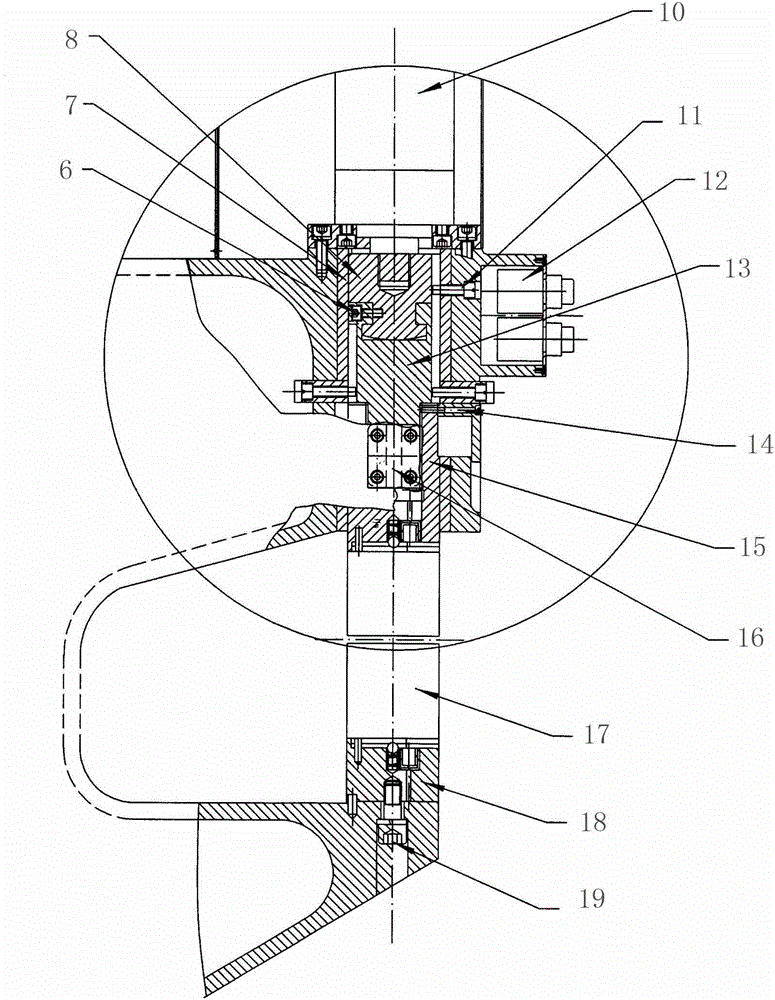

[0011] Such as Figure 1 to Figure 3 As shown, a rapid prototyping equipment for sheet metal parts is provided with a supercharger 4 above the base 2, a support 21 is symmetrically provided in front of the supercharger 4, and a connecting sleeve 20 is respectively provided at the inner end of the support 21. , the two connecting bushes 20 are jointly connected with the U-shaped bed 5; a gas-liquid conversion device 10 is arranged above the U-shaped bed 5, and the power input end of the gas-liquid conversion device 10 is connected with the supercharger 4, and the gas-liquid The output shaft of the conversion device 10 and the upper mold 20, while the upper mold 20 is located above the U-shaped groove opening of the U-shaped bed 5, and a mounting seat 18 is arranged below the U-shaped groove opening of the U-shaped bed 5. On the mounting seat 18 Connect the lower mold 17, the lower mold 17 is located below the U-shaped slot opening of the U-shaped bed 5, and corresponds to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com