Special framework for automotive front windshield decoration strip

A technology for windshields and decorative strips, which is applied to sealing devices, vehicle parts, transportation and packaging, etc. It can solve the problems of easy deformation and falling off, and the quality cannot meet the needs, so as to achieve the effect of simple skeleton structure and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

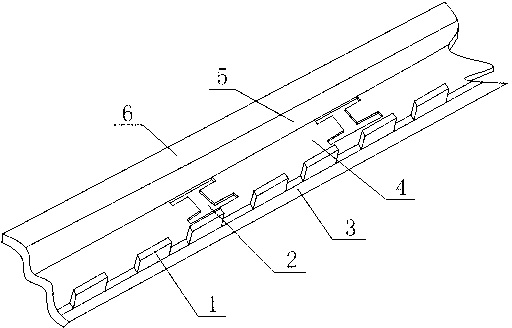

[0015] Such as figure 1 As shown, a skeleton dedicated to the decorative strip of the windshield of an automobile includes a support plate 4 in a cuboid shape, and a mounting plate 3 and a fixing plate 5 are vertically arranged on the support plate 4, and several mounting plates 3 are arranged on the mounting plate 3. The claw 1 and the fixing plate 5 are connected with a positioning plate 6 , and the positioning plate 6 is vertically connected with the fixing plate 5 , and several square holes 2 are arranged on the support plate 4 . The support plate 4 is a component that supports the skeleton. The support plate is fixed on other parts through the square hole 2, and the claw 1 fixes the skeleton. Multiple fixes make the skeleton installation stable, which can meet the functions of waterproof, dustproof and appearance decoration. It meets the needs of automobile production, and it will not deform and fall off after long-term use.

[0016] The square hole 2 is an I-shaped stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com