Compartment end face sealing device

A technology of end face sealing and compartments, which is applied in the direction of watertight door arrangement, engine sealing, engine components, etc., can solve the problems of complex manufacturing process, large volume, and heavy weight, and achieve simple manufacturing process, small volume, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific embodiments.

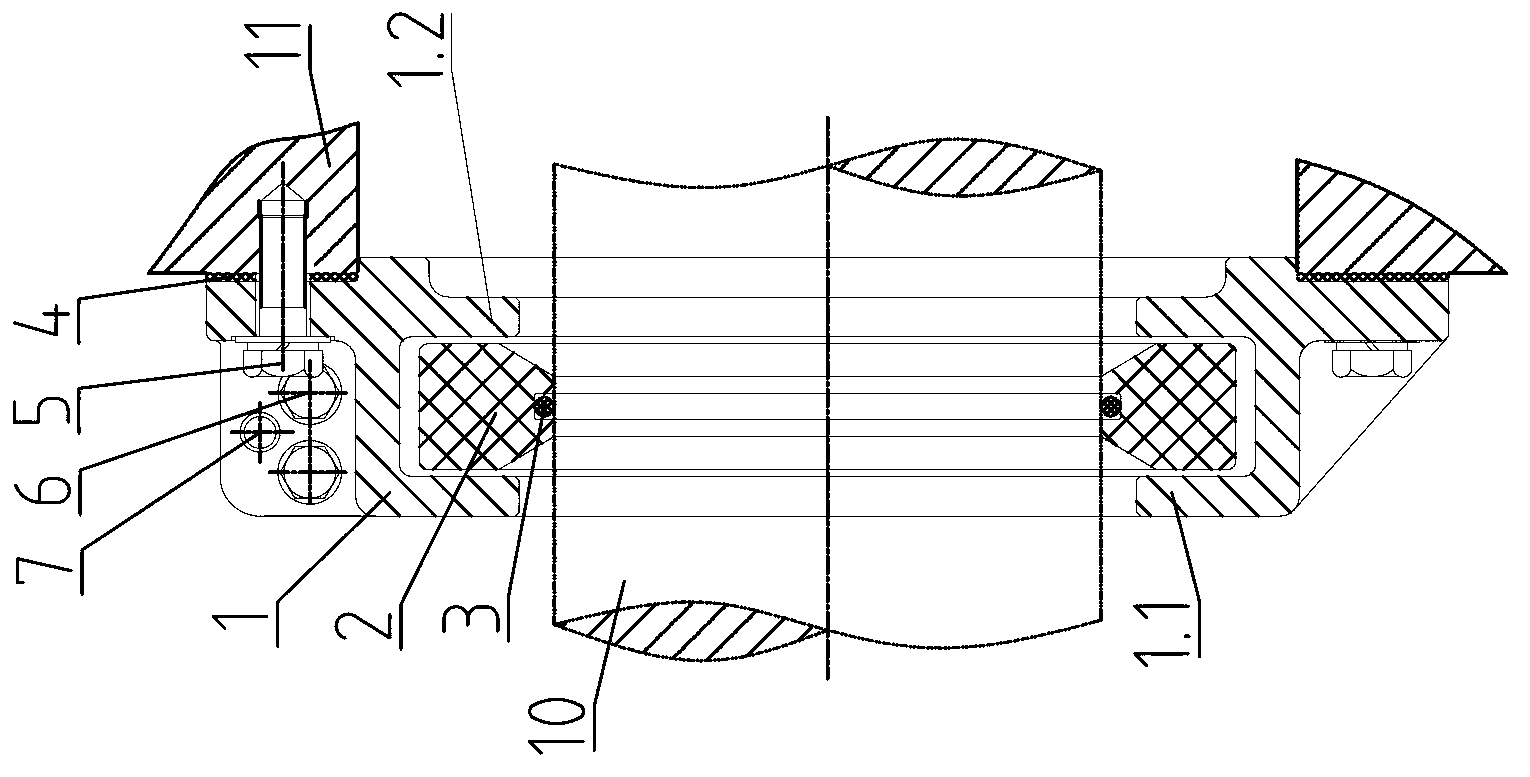

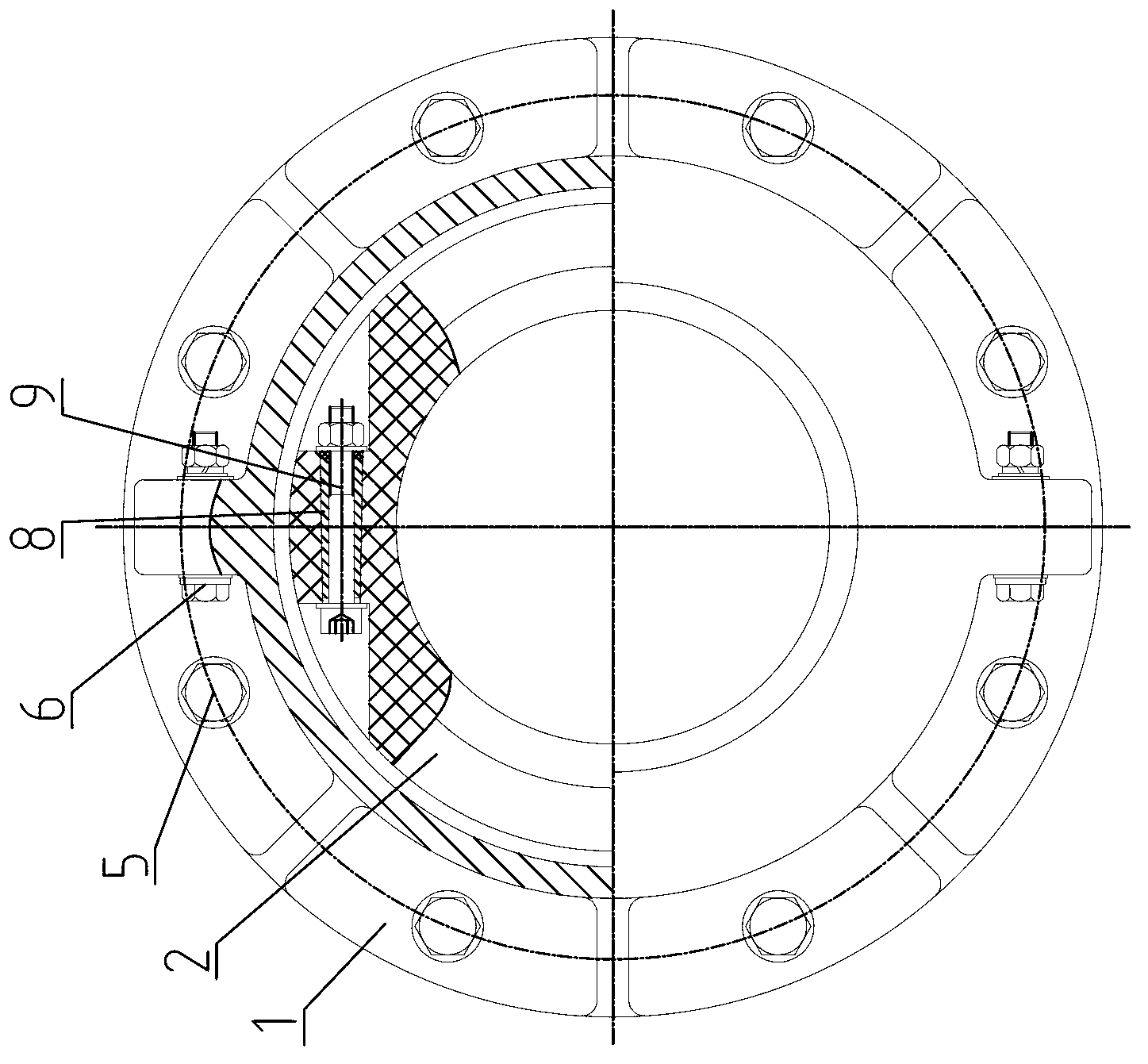

[0012] The compartment end face sealing device includes a ship shaft 10 and a ship bulkhead 11, a ring-shaped diaphragm 2 is slidingly sleeved on the ship shaft 10, and an O-ring 3 is provided at the middle of the inner circle of the diaphragm 2; A shell 1 is sealed and fixed on the ship bulkhead 11, and the shell 1 is sleeved on the ship shaft 10 at intervals; a left clamp ring 1.1 is integrally connected to the left end of the inner circle of the shell 1, and at the right end of the inner circle of the shell 1 The right clamping ring 1.2 is integrally connected with the part, and the diaphragm 2 is located between the left clamping ring 1.1 and the right clamping ring 1.2.

[0013] A gasket 4 is provided between the shell 1 and the ship bulkhead 11.

[0014] The housing 1 is a two-half split structure, and the two parts are connected by a first connecting bolt 6 and a positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com