Mechanized wine production line

A production line and liquor technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of not being able to complete the mechanized production line, going to work at three or four o'clock in the morning, and low production efficiency, so as to optimize working hours, reduce labor intensity, and improve production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

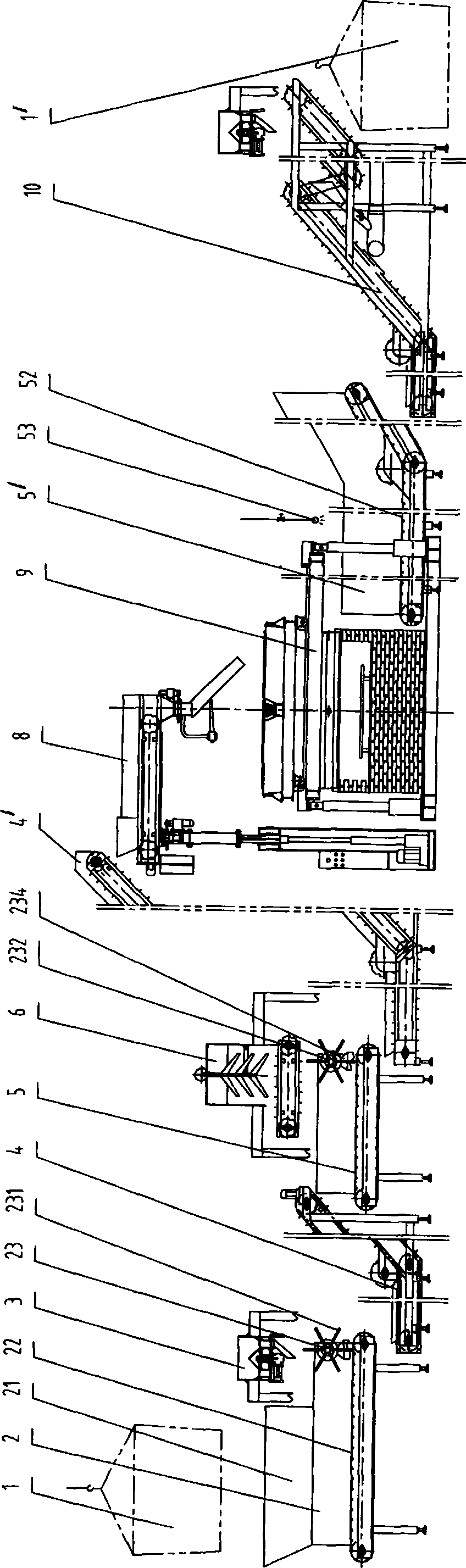

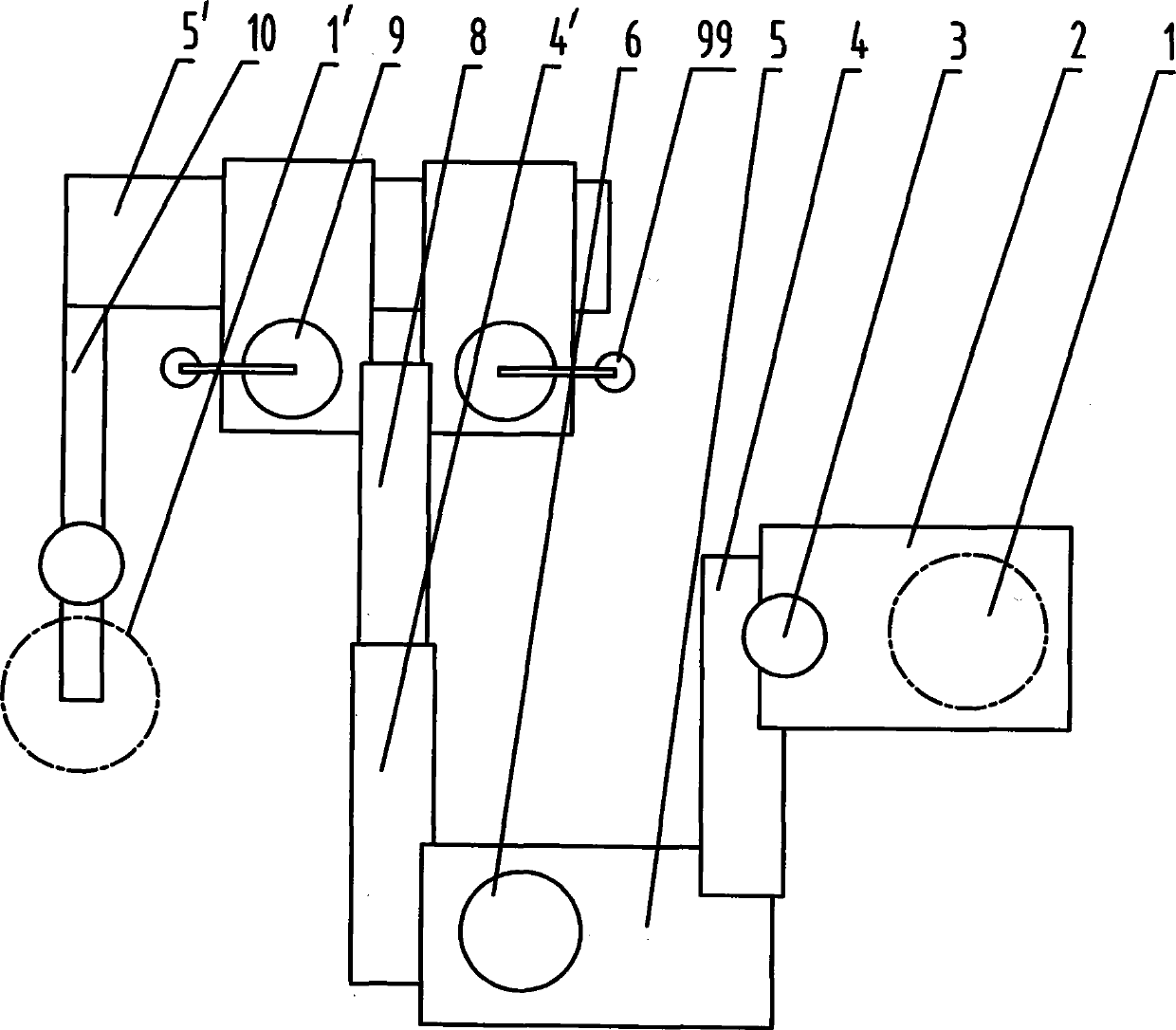

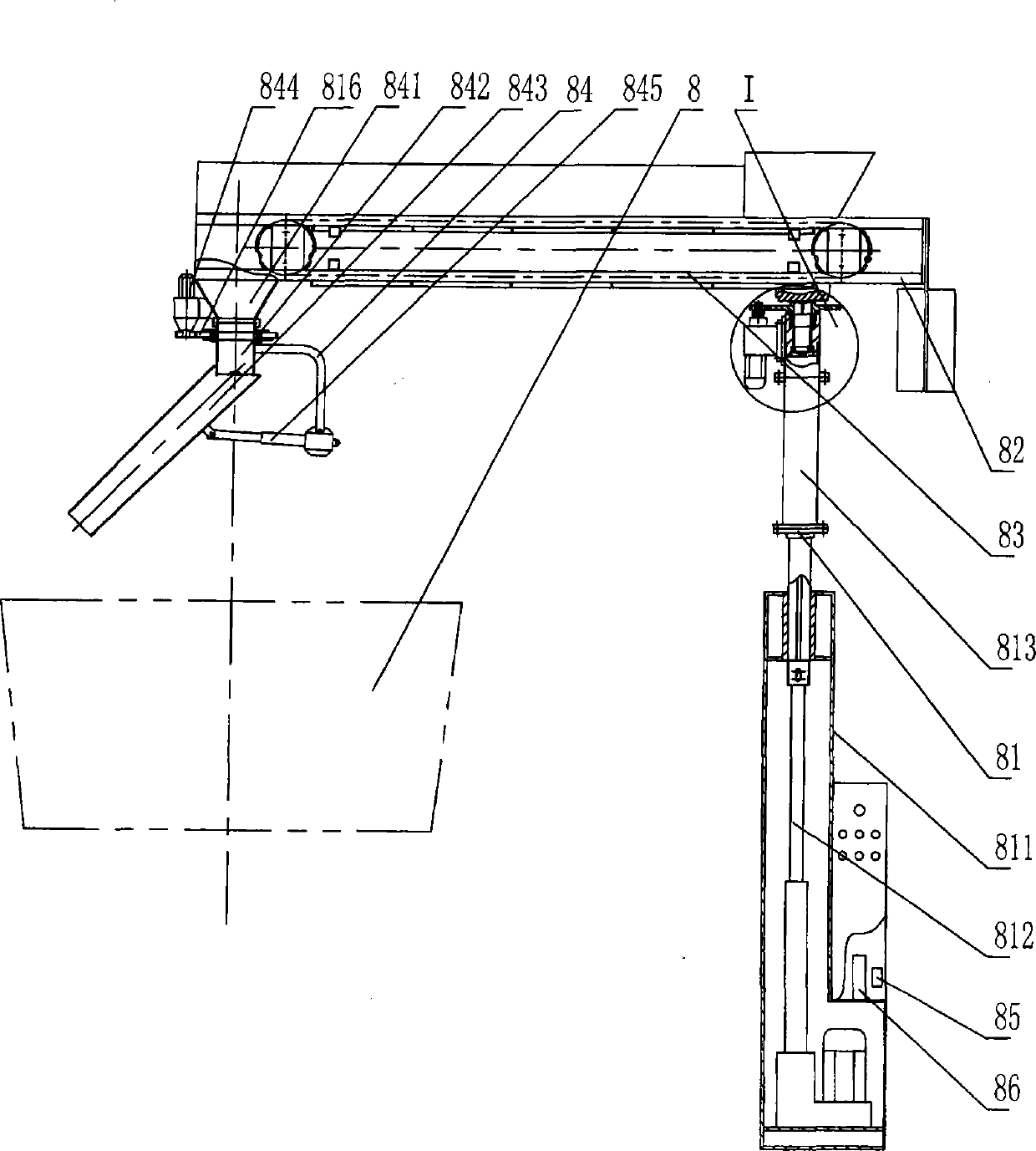

[0024] like Figure 1-10 As shown, the present invention includes grain grain homogenizer 2, grain grain conveyor I4, grain grain moistening machine 5, grain grain conveyor II4 arranged in sequence / , Automatic retort machine 8, Liquor automatic distillation machine 9, Water measuring automatic moistening machine 5 / 1. The automatic grain drying machine 10 is provided with a rotary feeder 3 above the outlet of the grain grain homogenizer 2 and the rear part of the automatic grain drying machine 10, and a rotary feeder 3 is arranged above the grain grain moistening machine 5 outlet. There is chaff husk uniform feeder 6, and condenser 99 is arranged next to liquor automatic distiller 9. There are 2 liquor automatic distillation machines 9 arranged side by side; 2 condensers 99 are respectively arranged on both sides of the liquor automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com